Dec 24, 2025

- Company

- Topics

- ESG Management

- Operating Company

- Awards

Oct 15, 2021

Company / Topics

Osaka, Japan – Panasonic Corporation’s Appliances Company (Kitchen Appliances Business Division*1 and Manufacturing Innovation Division’s AP Kato Plastic Recycling Plant*2), Manufacturing Innovation Division, and Panasonic ET Solutions Co., Ltd. have been honored with the Ministry of Economy, Trade and Industry Minister’s Award at the FY2021 Resources Recirculation Technologies and Systems Awards hosted by The Japan Environmental Management Association for Industry (JEMAI).

Under Japan’s Home Appliance Recycling Law, which entered into force on April 1, 2001, home appliance manufacturers are obligated to recycle materials from used air conditioners, TVs (CRT, LCD, and plasma), refrigerators/freezers, and washing machines/clothes dryers. Plastics used in home appliances can be sorted, recovered, and transformed into recycled plastics, but some materials—such as plastics containing glass fiber—are discarded since they cannot be separated. In addition, the challenge of eliminating residual odors from and recovering/controlling the physical properties of some recycled plastics has made it difficult to maximize their potential reuse. Concerns over quality have also hindered the adoption of recycled plastics.

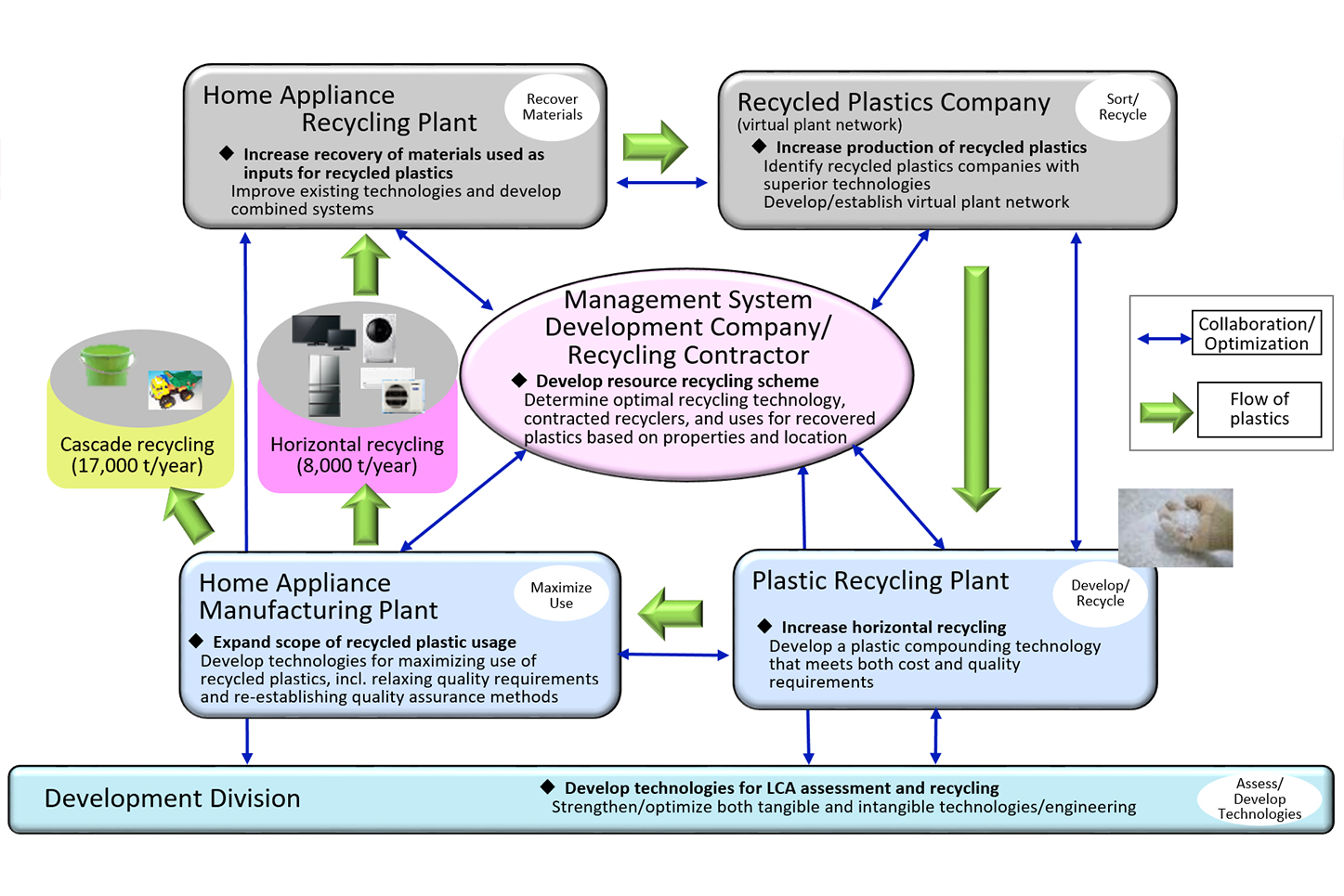

The award-winning project, “Development of a circular supply chain for plastics recycled from home appliances,” was implemented nationwide through close collaboration among relevant divisions within the Panasonic Group and partner companies for the purpose of overcoming the challenge of working with recycled plastics. The project included the following activities: increasing the volume of plastics recovered at home appliance recycling plants; developing a new type of low-cost, high-quality recycled plastic; enhancing plastic factory production volumes; maximizing the use of recycled plastics at home appliance factories; and designing a scheme to coordinate the entire process. Each division played a unique role and worked together to develop a nationwide circular supply chain that closes the loop for the recycled plastics life cycle.

The project has resulted in improved technologies for sorting plastic materials and higher quality recycled plastics. The evolution of technologies for maximizing the use of recycled plastics has made it possible to recycle 17,000 t/year of plastic through cascade recycling (plastics are recycled for use in products different from their source) and 8,000 t/year through horizontal recycling (plastics are recycled for use in the same products as their source). Furthermore, optimizing the scheme based on life cycle assessment has yielded a 95,573 CO2eq reduction in greenhouse gas emissions and a 1,337,299 GJ/year reduction in energy consumption.

Panasonic intends to further expand the utilization of recycled plastics by evolving its individual technologies and maintaining high standards. It will also continue to promote collaboration and knowledge sharing with related companies to contribute to the realization of a circular economy.

*1: Name of the organization at the time of award application; as of October 1, 2021, the name has been changed to: Panasonic Corporation, Lifestyle Updates Business Division, Living Appliances and Solutions Company, Kitchen Appliances Business Division

*2: Name of the organization at the time of award application; as of October 1, 2021, the name has been changed to: Panasonic Corporation, Lifestyle Updates Business Division, Living Appliances and Solutions Company, Business Process Innovation Division, Environmental Promotion Center

The content in this website is accurate at the time of publication but may be subject to change without notice.

Please note therefore that these documents may not always contain the most up-to-date information.

Please note that German, Spanish and Chinese versions are machine translations, so the quality and accuracy may vary.