Dec 25, 2025

- Products & Solutions

- Stories

- Technology

- AI & Robotics

- R&D

- Business Solutions

Jan 26, 2016

Products & Solutions / Topics

Panasonic Factory Solutions Co., Ltd.

Simultaneously achieve high productivity and high accuracy placement

|

Model ID |

Production Modular, NPM-TT2 |

|

Model No. |

NM-EJM1E |

|

Productivity |

36,000cph*1 |

|

Head |

8-nozzle head, 3-nozzle head |

|

Applicable components |

0402 to L120 x W90mm x T30mm or L150 x W25mm x T30mm |

|

Applicable PCB |

Dual-lane mode 50 x 50 to 510 x 300mm |

|

Start accepting order |

February 2016 |

Panasonic Factory Solutions Co., Ltd., a business unit of Panasonic Corporation, announced today that it will begin taking orders for its New Production Modular, NPM-TT2 (Model No. NM-EJM1E) in February, 2016. The NPM-platform supports Surface Mount Technology (SMT) processes including component mounting, adhesive dispensing, and inspection of printed circuit boards.

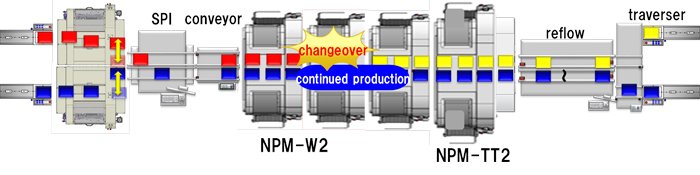

Flexibility is critical in today's SMT factory and the NPM-TT2 adapts to a wide variety of manufacturing conditions and characteristics such as different production volumes and variation in component packaging. The NPM-TT2 reduces system changeover time, therefore, helps customers meet market requirements of shorter product life cycles.

Beyond evolving with the markets' needs, the NPM-TT2 was also designed for increased productivity and yield of large, odd-form component placement with our award winning, new multi-recognition camera, and other improved technologies.

Panasonic continues to provide customers with solutions such as the NPM-TT2 for the SMT process and contribute to the reduction of TCO*2.

Akio Kaneko

Corporate Planning Group

Panasonic Factory Solutions Co., Ltd.

TEL : 055-275-6786 FAX : 055-275-6071

Homepage URL http://www.panasonic.com/jp/company/pfsc.html

*1 cph : Chip Per Hour

Number of chips that can be placed per hour

*2 TCO : Total cost of Ownership

Total cost to purchase, maintain and manage equipment, etc.

The NPM-TT2 Production Modular

The content in this website is accurate at the time of publication but may be subject to change without notice.

Please note therefore that these documents may not always contain the most up-to-date information.

Please note that German, Spanish and Chinese versions are machine translations, so the quality and accuracy may vary.