From extraction to recycling, making use of cellulose fiber, a strong but light-weight material that can be sourced from industrial waste.

Over 300 million tons of plastic waste is produced each year worldwide, half of which is designed to be used only once and only 9% of all plastics are being recycled. The environmental cost of single-use plastics is high and is a problem that needs to be addressed urgently. Since 2015, the Panasonic R&D team has been researching a more sustainable material and developing a resin that is a highly functional and reusable with a lower environmental impact--by using the cellulose fiber.

Cellulose fiber is made from a natural fiber, the cellulose fiber, found in all plants. It can be made from plant waste (e.g. wood waste, coffee husk) or from plant materials like wood, making it a sustainable resource as it can also be reproduced by recycling plant derived waste materials.

Reducing the environmental impact with an innovative defibration process

The team has been developing a strong, flexible and light-weight material by compounding cellulose fiber into resin. A special and innovative dry defibration process has been created, which does not use water. Decreasing the number of steps and using less energy in the process translates into lower energy costs and CO2 emission and improved productivity: reducing 1.8 kg of CO2 per kg of cellulose. In addition, the team has considered the recycling aspect of this material. Panasonic's proprietary, highly accurate near infrared sensor sorting system can sort the recycled materials based on each resin type, which ensures that the recycled material maintain its durability relatively and can be reused.

Examples for incorporating cellulose fiber into products

The cellulose fiber material can be used for many different kinds of products as the following two examples can demonstrate.

-

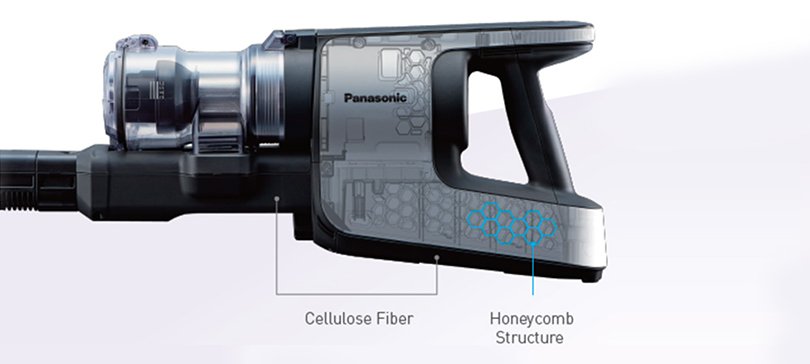

The chassis of Panasonic's cordless stick vacuum cleaners, MC-SBU820J/MC-SBU620, introduced in August 2018: The cellulose fiber used boasted approximately eight times the impact resistance of glass fibers, and in addition to its durability, it also successfully reduced the amount of plastic used in the product. This was the first time that the cellulose fiber material has been used in a home appliance product in Japan.

-

Teaming up with Asahi Breweries, Panasonic developed a reusable cup for drinking beer, christened the "Forest Tumbler" due to its wooden look and texture. The cup was verified to hold the head of a beer, containing bubbles 1/5 of the size found in plastic cups in proprietary testing at Asahi Breweries.

These examples show the potential for using cellulose fiber material in a large variety of products of any kind.

The future of cellulose fiber outlook for more sustainable materials in products

Not only are consumers increasingly aware and consider sustainability when making purchases, many governments worldwide are also taking action. For example, EU is tackling plastic pollution and marine litter, and is accelerating the transition to a circular plastics economy, as described in the EU Circular Economy Action Plan and the EU Single-Use Plastics Directive.

As demand intensifies for sustainable materials across all industries, Panasonic has been working to enhance the strength and durability of the material incorporating variations of the levels of the cellulose fiber. Such variations will allow for different properties suitable for a diverse range of applications.

Panasonic aims to reduce the use of virgin plastic resin derived from mineral oil and ultimately, make use of materials produced from natural resources in order to contribute to more sustainable materials.

# # #

Disclaimer:

We would like to note that Panasonic Newsroom is not a place to address personal Customer Service issues. Even though this is not the forum, Panasonic is always eager to resolve your concerns. Our local customer services contacts can be found at Global Support or you can see our list of Social Media Accounts to find the right channel for your queries and concerns.