Worldwide, more than 300 million tons of plastic is being consumed every year. On the other hand, it is said that only 14% is being recycled (according to documents published by the United Nations Environment Programme). As we face issues such as plastic waste polluting the sea, declining oil fields, and global warming, there is a global urgency to reduce petroleum-based plastics.

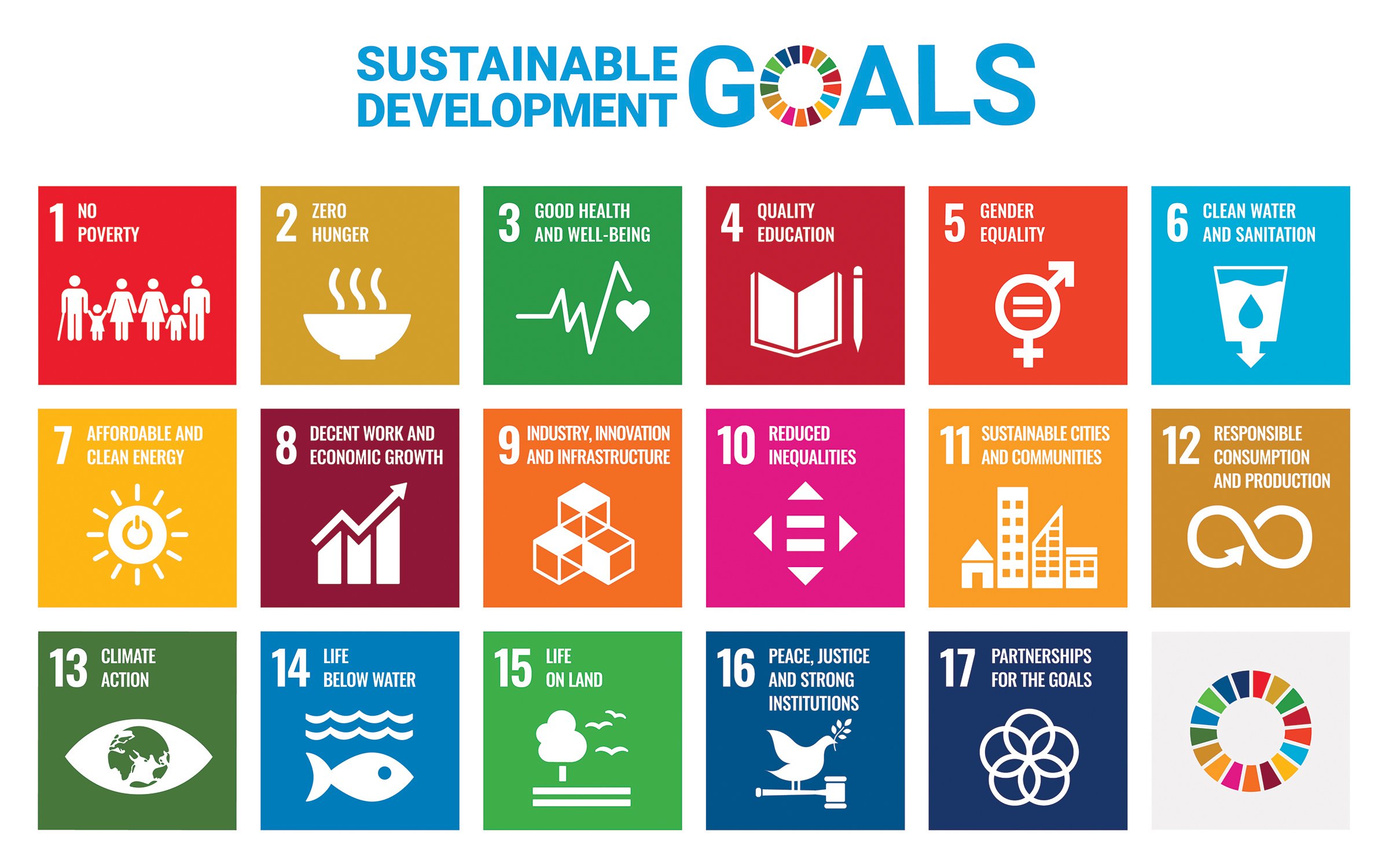

Sustainable Development Goals (SDGs) were adopted by all member states of the United Nations in 2015 as a universal call to action to realize a better, sustainable world. In it, the UN has identified "Achieve the efficient use of natural resources" and "Prevent and significantly reduce marine pollution" as important goals.

To answer this call to action and reduce the amount of plastic used, Panasonic, which has over 300 manufacturing sites around the world, began its research and development of eco-conscious materials in 2015. What Panasonic focused its attention on was plant-derived cellulose fiber. This light, but strong eco-conscious biomass molding material is made by extracting fiber from cellulose, a key composite of plants, fibrillating, and mixing it with resin as a reinforcing agent.

Cellulose fiber is made from pulp, which comes from trees, a recyclable natural resource. It has drawn attention as a sustainable resource that can, unlike fossil fuels, be reproduced by strategically planting trees.

Traditionally, cellulose fiber had to be extracted from pulp by fibrillating the pulp in water. The cellulose fiber must then be dried before it can be mixed with resin, and the energy and cost required to do so had been a challenge in the past. Panasonic developed a proprietary process that is completely dry by fibrillating pulp in molten resin rather than water. By getting rid of the drying process, Panasonic made it possible to manufacture cellulose fiber more efficiently.

The cellulose fiber resin created by applying this completely dry process was used for the chassis of Panasonic's cordless stick vacuum cleaners, MC-SBU820J/MC-SBU620, introduced to the market in August 2018.

Cellulose fiber is also easier to process and recycle. When you burn composite materials made from cellulose fiber resin, because it is plant-based, nothing remains. Moreover, with Panasonic's proprietary, highly accurate near infrared sensor sorting system, materials can be sorted based on each resin type, thus it can be reused as recycled materials whilst relatively maintaining durability.

In 2019, Panasonic developed a composite processing technology that enabled it to mix cellulose fiber with resin at a high concentration of 55%. Panasonic has also ensured coloring freedom during the molding process, which allows it to give the resin a unique wooden texture befitting of the raw material and even aroma.

And the same year, Panasonic developed reusable cups made from high density cellulose fiber molding material. Awareness for mitigating environmental impact has increased over the last couple of years, so reusable cups have started to be widely adopted at theme parks, concerts, and sporting venues. Reusable cups with added value such as designed to commemorate events or bearing images of artists and athletes are starting to become a collectors' item. Panasonic is also using reusable cups in the cafés in its showrooms and distributing reusable cups featuring unique designs. Panasonic will continue to use reusable cups with the hope that they will offer people an opportunity to think about the environment and recycling of resources.

At the café "Re-Life ON THE TABLE" in Panasonic Center Osaka, Panasonic's corporate showroom, reusable cups are used to serve drinks and sweets. They can also be purchased for home use.

Since its foundation, Panasonic's mission has been to realize both "a better life" and "a sustainable global environment." To do so, under the concept, "from product to product," Panasonic has extracted resources from used products to achieve "circular manufacturing." To contribute to these efforts, Panasonic will make further improvements (e.g. toughness, durability) to the cellulose fiber molding material, so that it may be used for other applications and help reduce the amount of plastics used.

Panasonic will continue to also contribute to the realization of a circular society by developing new eco-conscious materials. Please look forward to more from Panasonic.

To develop cellulose fiber molding material, Panasonic utilized the findings from the following projects consigned by the Ministry of the Environment.

1. FY2015-FY2017, Development of technology to reduce CO2 emissions during the cellulose nano fiber production process.

2. FY2016-FY2017, Performance evaluation of consumer electronics utilizing cellulose nano fiber and testing its implementation.

3. FY2017-FY2019, Performance evaluation of cellulose nanofiber recycling, etc.

SDGs Seminar Held ahead of EcoPro Online 2020!

EcoPro 2020, one of the largest environmental exhibitions in Japan will be held online this year.

Ahead of the exhibition, Panasonic will organize an online seminar on October 28, 2020. Panasonic will introduce efforts it is undertaking to achieve the SDGs and will also invite external experts to discuss both from the point of view of companies and consumers how it should realize "a better life" and "a sustainable global environment" by bringing to life a circular economy, a new economic model for achieving SDGs that has been drawing attention.

Panasonic's SDGs seminar: "A circular economy and a sustainable lifestyle it can bring to life" (Japanese Only)

Date: October 28, 2020 18:00-19:30 (JST)

Participants: The seminar is open to all, so please register from http://ptix.at/oEIvJa

For details about the seminar and speakers, please click on the link below:

https://news.panasonic.com/jp/topics/203951.html (Japanese)

And in November, Panasonic will hold a seminar to introduce its plans to expand the use of renewable energy and to discuss the "Eco Island Miyakojima" project and the key town building solutions to be implemented with partners working on the project.

Please click on the link below for more information about the seminar and speakers.

Panasonic's SDGs seminar: "Energy local production and consumption challenge in Japan's tropical island Miyakojima"

https://news.panasonic.com/jp/topics/203991.html (Japanese)

EcoPro Online 2020

Period: November 25 to 28, 2020, 10:00-17:00 (JST) *Archives will be available after the exhibition until December 25, 2020.

Venue: Online

Organizers: Sustainable Management Promotion Organization, Nikkei Inc.

# # #

- Disclaimer:

- We would like to note that Panasonic Newsroom is not a place to address personal Customer Service issues. Even though this is not the forum, Panasonic is always eager to resolve your concerns. Our local customer services contacts can be found at Global Support or you can see our list of Social Media Accounts to find the right channel for your queries and concerns.