As soon as the global threat from the coronavirus became apparent one year ago, the race was on to develop vaccines that would offer protection and allow normal life to resume around the world. Understandably, much attention has since focused on the incredible speed at which these vaccines have been developed, tested and manufactured in bulk.

But getting billions of vaccine shots transported from manufacturing plants around the world to distribution points in each country and delivered from these to local medical facilities--all within low and tightly controlled temperature ranges--would also prove to be challenging, both in terms of the logistics and the new cold storage technology required along the way.

Enter Panasonic. Long a trusted brand in the field of consumer electronics, the company was already an industry leader in the development of plasma display technology and refrigeration techniques. Following a chance conversation between the heads of these two development teams, the idea was hatched to utilize plasma display technology in the development of new vacuum insulation techniques and to leverage this in the creation of more advanced refrigeration capabilities. The new VIXELL cooling box solution was the outcome.

Explains developer Shinya Kojima, "To begin with, my team's efforts were focused on developing improved cold storage capabilities for food. But with the growing need for the safe transportation of medicines at tightly controlled temperatures--even prior to the COVID-19 pandemic--our focus switched to this more specialized area of transportation."

Added developer Hideji Kawarazaki, "New generations of medicines and vaccines are increasingly expensive, so any waste resulting from improper temperature control during transit can be very costly. Then along came COVID-19, which brought a whole new level of urgency. That spurred us to redouble our efforts and develop more advanced refrigerated solutions at record speed."

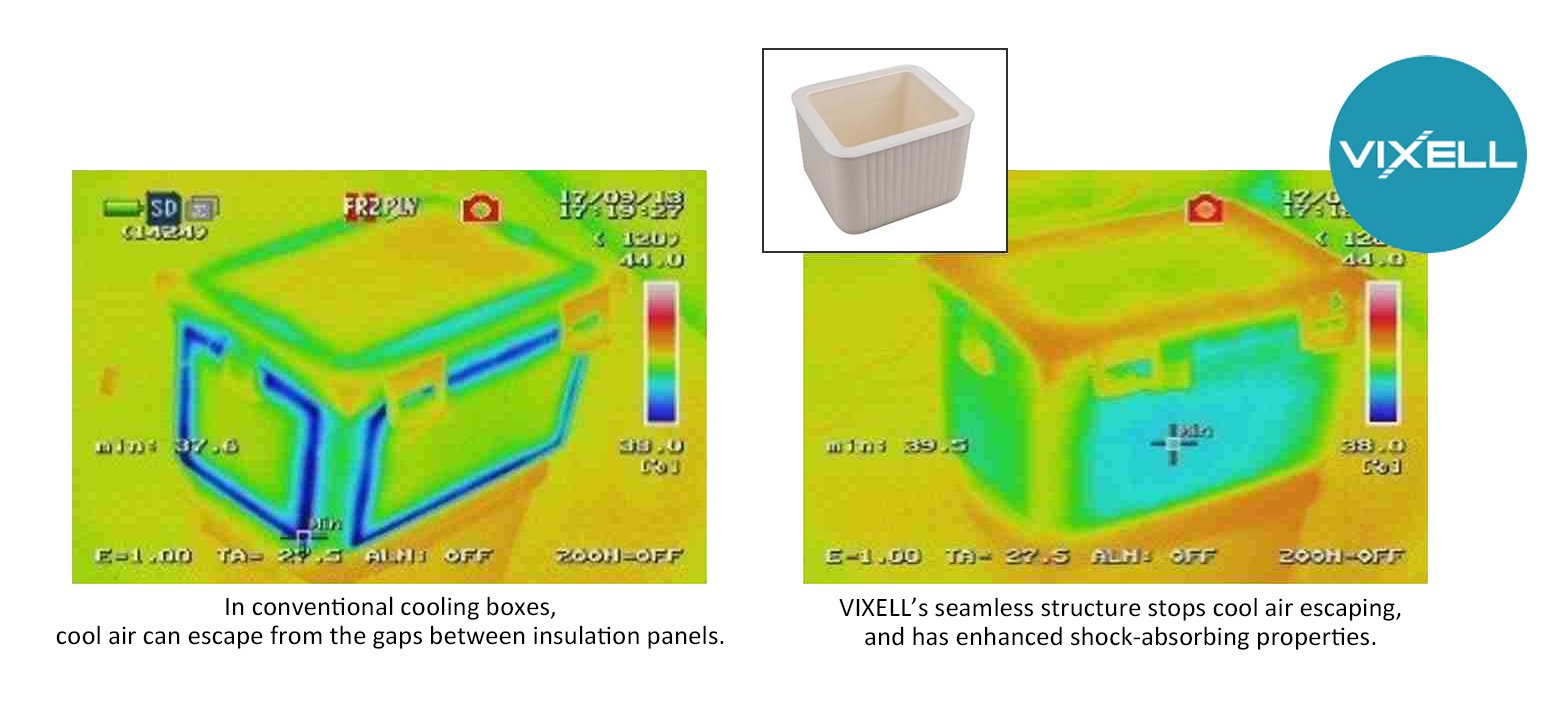

There are a number of drawbacks with conventional cold carrier boxes, explained Kojima. Gaps often open up between their internal insulation layers, leading to temperature leakage. In addition, they are wrapped in aluminum film, which prevents any radio or magnetic field penetration and makes remote monitoring of their internal temperature impossible. In order to check the conditions inside a box, it is necessary to open it, compromising the internal temperature.

A further drawback of conventional vacuum-insulated products is that at very low temperatures they become quite brittle and more susceptible to accidental damage during transportation or after prolonged use. This can lead to a deterioration in their vacuum integrity, and in turn reduce insulation performance.

To address these drawbacks, the Panasonic teams harnessed the company's proprietary vacuum insulation technology, using advanced cast-molding techniques to develop new seamless urethane foam insulating material. This has no gaps between the insulation layers, so coolness retention is significantly improved. The new insulation also requires no aluminum foil wrapping, allowing the condition of the box contents to be verified wirelessly using external monitors. Finally, VIXELL's new shock-absorbing structure softens any impacts and reduces the risk of damage if the box is roughly handled or dropped.

Equipped with the new insulation and using regular dry ice, the VIXELL containers can maintain temperatures as low as minus 70C for up to 18 days without any power.

A pre-installed wireless vacuum sensor utilizing contactless power supply technology allows handlers to instantly check the internal condition of the box by placing it on a dedicated powered inspection stand. Even the temperature inside the box can be monitored through the use of a wireless monitoring device.

Hideji Kawarazaki, Manager, Engineering Division, demonstrates remote monitoring of the internal condition of a cooling box using the powered inspection stand.

As well as facilitating transportation at precise low temperatures, the new VIXELL boxes will allow distribution centers and clinics without dedicated cold storage facilities to store the vaccines temporarily, further smoothing the distribution process. Their design also allows for the internal refrigeration units to be swapped at any time, which means that individual units can be used to transport and store contents at different temperatures.

Panasonic is partnering with Suzuken, a Japanese company active in the pharmaceutical wholesale business, in the marketing of VIXELL.

For now, Panasonic will lease the VIXELL containers to ensure that they are used in optimum conditions. They will initially be available only in Japan, but Kojima confirmed that Panasonic aims to make them quickly available in other countries, to help reduce the risk of supply shortages as COVID-19 vaccination efforts ramp up worldwide.

Reflected Kawarazaki, "Panasonic has designed and manufactured products for years that have helped consumers lead more comfortable and enjoyable lives. This time, the focus was on developing something that would help society at large. I feel a sense of pride in that we were able to step up so quickly and deliver this in support of the global COVID vaccination effort."

"Actually," he added after a pause, "for many of us on the teams that worked together on this, it's a dream come true."

# # #

Disclaimer:

We would like to note that Panasonic Newsroom is not a place to address personal Customer Service issues. Even though this is not the forum, Panasonic is always eager to resolve your concerns. Our local customer services contacts can be found at Global Support or you can see our list of Social Media Accounts to find the right channel for your queries and concerns.

Related Links

Related News

Related Videos

VIXELL™ - A Vacuum-insulated Cooling Box for -70ºC Storage