Video updated on Feb 25, 2021.

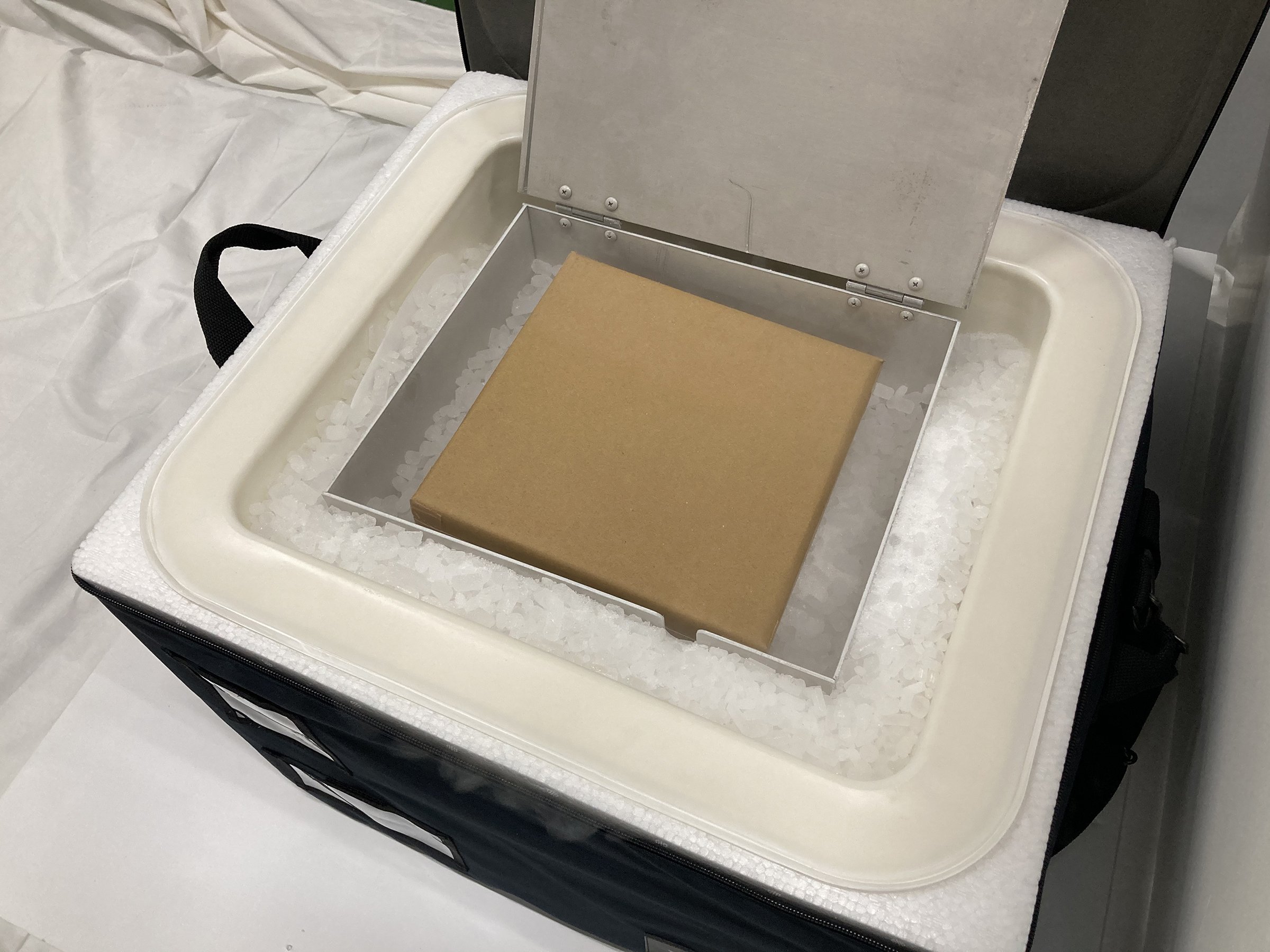

Osaka, Japan - Panasonic Corporation has developed VIXELL™, a vacuum-insulated box that can store items in a -70ºC environment for up to 18 days*1 using refrigerants such as dry ice.

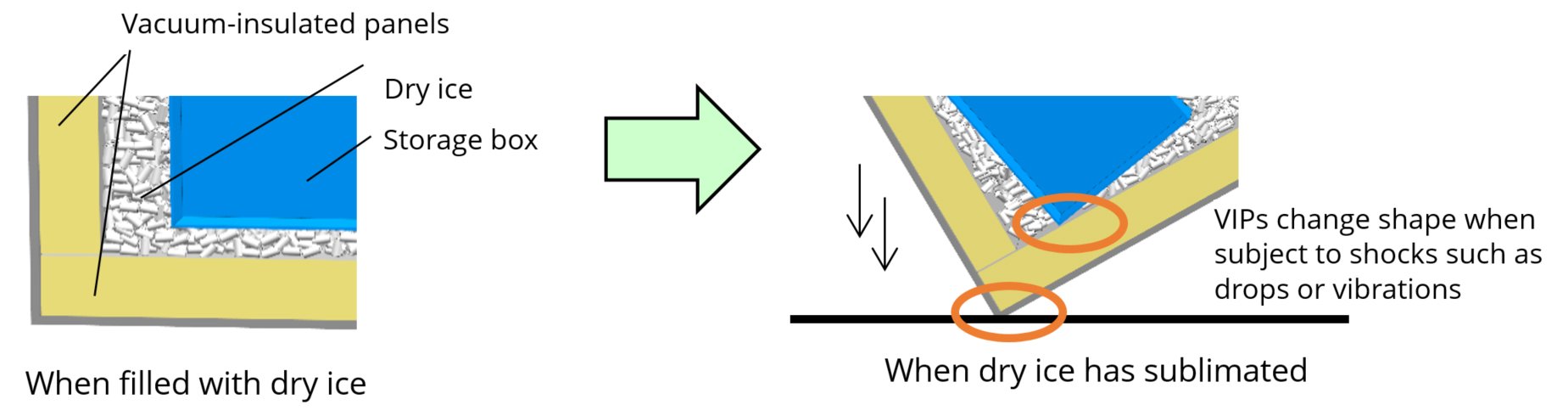

The transport of vaccines and other medical supplies requires strict temperature control. Up until now, conventional insulated boxes have been manufactured by joining vacuum-insulated panels (VIPs) together, but a drawback of this structure has been that cool air leaks through the gaps where the panels join. Panasonic has long been engaged in the research and development of VIPs, and has used them to reduce energy usage in refrigerators and other products. Utilizing its accumulated technologies and expertise, the company has eliminated this leakage--an inevitable issue when using VIPs--through the development of VIXELL™. VIXELL™ boxes are created using a proprietary cast-molding method which completely prevents cool air from escaping through gaps seen in conventional boxes. The 57-liter type uses urethane foam and glass wool as insulating material, and compared to previous Panasonic prototypes, improves coolness retention performance by around 30%.*2

Inside VIXELL™ boxes are thermal storage units, and the temperature is maintained by filling the inside and outside of these units with refrigerant. By switching the types of these units and refrigerants, VIXELL™ can accommodate a diverse range of temperature zones, including the dry ice temperature zone*3 (below -70ºC), the below -20ºC zone, and the 2ºC-8ºC zone.

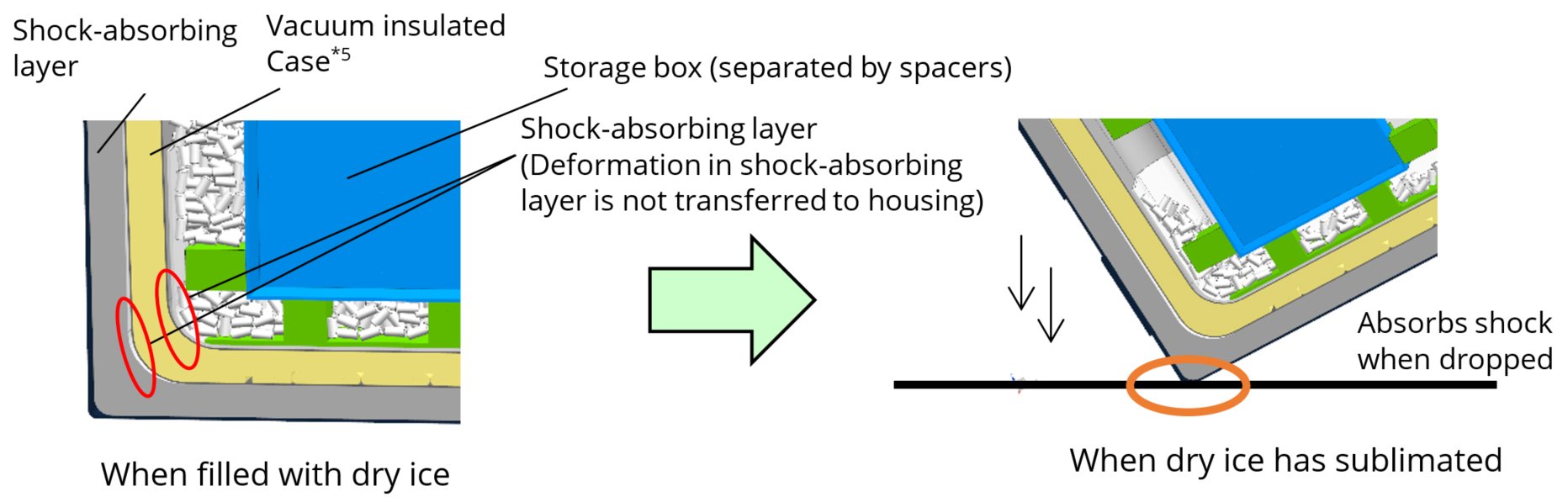

Until now, the insulating material used in these cooling boxes has been covered in a plastic sheet. When using dry ice as a refrigerant, however, the temperature of this plastic drops below the "brittle temperature,"*4 meaning it is more prone to damage when subjected to drops or vibrations during transport. The shock-absorbing structure of VIXELL™ reduces the risk of damage to this plastic sheet. This has enabled reliable, stable transportation even in the dry ice temperature zone.

Panasonic will begin offering samples of VIXELL™ to pharmaceutical and logistics companies at the end of FY2021 ending in March 2021 with the aim for commercialization as soon as possible.

Features

-

Cast molded for outstanding thermal insulation

The cast-molded box structure ensures cool air doesn't escape through gaps in VIPs. The 57-liter type uses both urethane foam and glass wool as insulating material, and compared to previous Panasonic prototypes, improves coolness retention performance by around 30%.*2

-

Coolness retention performance that caters to frozen transport below -70ºC

The vacuum-insulated box contains a dry ice temperature zone thermal storage unit, and can maintain a -70ºC environment for up to 18 days*1 when filled with dry ice.

-

Shock-absorbing structure

When a vacuum-insulated box--which has been cooled to dry-ice temperature--is dropped or accidentally subjected to any other shock, the brittle plastic sheet covering the box is easily damaged. VIXELL™'s new shock-absorbing structure mitigates shock and reduces the risk of damage when the box is dropped.

*1: Testing conditions: 120-liter-type vacuum-insulated cooling box with a 23-liter capacity dry ice temperature zone thermal storage unit, and 34 kg of dry ice inside the cooling box and the storage unit. The test measured how long the cooling box maintained a temperature of below -70ºC with an outside temperature of 30ºC. Under the same conditions but with a 9-liter capacity thermal storage unit and 14 kg of dry ice, the 57-liter type box maintained a temperature of below -70ºC for up to nine days.

*2: When comparing a previous Panasonic prototype with a 57-liter-type vacuum-insulated cooling box with an 8-liter capacity thermal storage unit (2ºC-8ºC temperature zone). The test measured how long the 2ºC-8ºC temperature zone could be maintained with an outside temperature of 35 ºC.

*3: Around -79ºC, the temperature at which dry ice sublimates.

*4: Based on the JIS K7216 testing method for the brittleness temperature of plastics, the temperature at which 50% of the plastic is damaged. The "brittle temperature" differs depending on the type and grade of plastic.

*5: Molded insulating material covered in a material with high gas-barrier properties in a vacuum state.

# # #

Disclaimer:

We would like to note that Panasonic Newsroom is not a place to address personal Customer Service issues. Even though this is not the forum, Panasonic is always eager to resolve your concerns. Our local customer services contacts can be found at Global Support or you can see our list of Social Media Accounts to find the right channel for your queries and concerns.

Related Links

- Appliances Company [Global/English] [Japanese]

- Panasonic R&D Overview

![[Video] Panasonic Stories in 60 Sec: Panasonic HX](http://news.panasonic.com/uploads/tmg_block_page/cover_image/18401/60sec-panasonic-hx.jpg)

![[Video] Panasonic Stories in 60 Sec: Robot Control Platform Robo Sync](http://news.panasonic.com/uploads/tmg_block_page/cover_image/18349/60sec-robo-sync.jpg)