Feb 20, 2026

- Company

- Stories

- Business Policy

- Financial Reports

A variety of technologies have taken root in our daily life, making it difficult to imagine our lives without them. Here, we introduce some examples of the Panasonic Group's technologies that have become integral to people's lives. These technologies have been developed after many trial-and-error efforts to meet the social challenges and customer needs of each era.

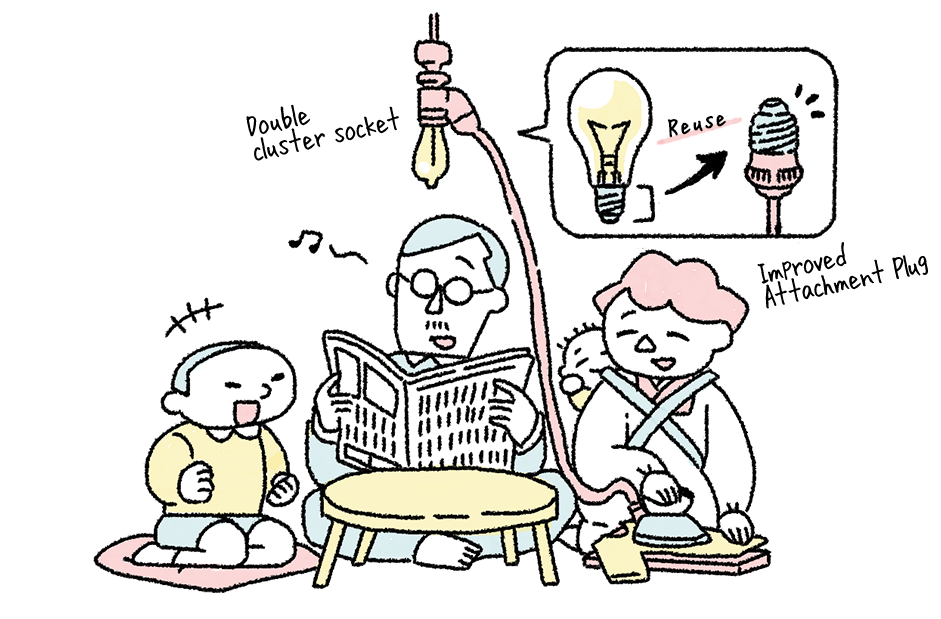

The Panasonic Group has been manufacturing wiring fixtures for over 100 years, and it has continuously expanded and upgraded its product line to meet the needs of the times. The improved attachment plug of 1918 was the company's first product, marking a pioneering achievement in safe, comfortable, and convenient products.

Two years after introducing the improved attachment plug (left), the double cluster socket (two-way socket) was developed.

In the late 1910s, attachment plugs for connecting cords to electric light sockets, serving as power outlets in homes at that time, became increasingly popular. However, they had problems such as poor machining accuracy of the threads used to screw the plug into the socket. Therefore, the founder Konosuke Matsushita tried and failed until he came up with the idea of reusing the screw bases of burned-out incandescent lamps from well-known manufacturers, resulting in a high-quality product at a price 30% lower than the competition. These dual advantages, combined with an innovative design, made the product well received. Later, referring to the inclusion of Contribution to Society in the Seven Principles, Konosuke said, "Since the improved attachment plug, we have consistently followed the policy of making no unjust profit while contributing to society."

Pursuing differentiation and marketability

In fact, in 1917, before founding the company, Konosuke launched an improved socket for use in electrical work, but this product did not sell at all, bringing his efforts to a standstill. This failure made him realize the importance of creating marketable products. As a result, he differentiated his attachment plug from similar devices with prices and designs more suitable for the general public. Such innovative efforts were the key to success.

Rechargeable batteries store energy so that it can be used as electric power whenever necessary. The technologies of Matsushita Electric and SANYO Electric, once fierce rivals in the battery business, have been integrated, thus accelerating efforts to contribute to people's lifestyles and society.

Rechargeable batteries have evolved along with the increase in cordless home appliances in Japan, and they continue to evolve with advances in technologies that make them more miniature, lightweight, and higher capacity. In the late 1950s, the two companies each launched its own development of nickel-cadmium batteries and carried on research and development to improve reliability as well as ensure a sealed structure, which eventually contributed to the miniaturization of video cameras. Following the development of nickel-metal hydride batteries with a higher energy density, they were adopted in laptop computers and mobile phones in the 1990s, providing reassurance that devices could last longer without having to recharge. In the late 1990s, lightweight, higher-energy density lithium-ion batteries emerged, dominating the rechargeable battery market. Due to increased concerns over environmental and energy issues with the coming of the 2000s, the focus shifted from consumer to automotive batteries. In the EV battery market, the Panasonic Group is pursuing technological innovation to maintain a presence in the North American market, where there is a particularly high need for higher-capacity batteries to achieve a longer driving range. This evolution was backed by the discovery of new materials, providing higher capacity and energy density, as well as higher levels of technological capabilities to promote the relentless pursuit of product improvement.

Panasonic's first lead-acid battery for automobiles (1937), which marked its entry into the rechargeable battery bussiness, was continuously improved with lead powder produced in-house as high-quality material was difficult to procure in wartime.

Cylindrical automotive batteries , from left: 1865, 2170, 4680

Technological innovations have continuously overcome customer and social challenges

The strengths are supported by the Panasonic Group's technological capabilities honed over 100 years of history in the battery business, as well as the capabilities in creating markets to fundamentally solve issues facing customers and society. A further source of the Group’s strength is its users' trust and its track record, which have been built up day after day with a policy of absolute safety and quality that does not permit manufacturing without a full commitment to these values. While meeting customer demands, the Group will pursue ever-higher capacity and power density through technological innovations to constantly enhance its product strengths.

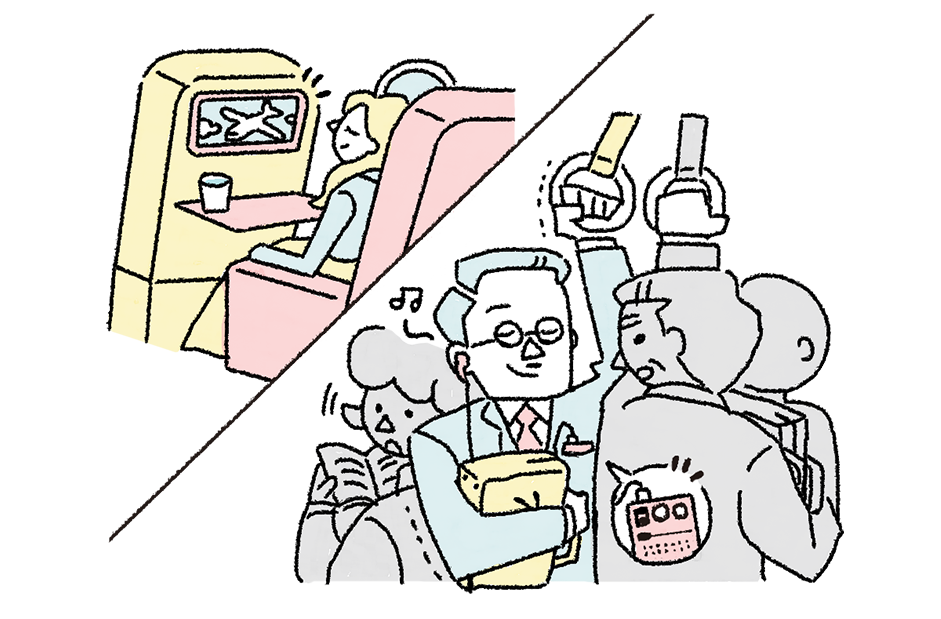

In the 1970s, Panasonic’s radio business had stagnated due to competition from Southeast Asian products. However, the 1977 release of the Pepper R-012, an innovative 12.7-mm thin radio, changed all that.

While Konosuke Matsushita had high expectations for Pepper, he insisted that the development team be mindful of cost and time to market and, moreover, that basic performance not be compromised by its thinness. Therefore, company-wide efforts were made to innovate the technology for mounting components on printed circuit boards while automating this mounting process. At the same time, the team also developed ultra-small and thin components, such as a 9.5-mm-thick miniature speaker, a synthetic resin speaker diaphragm, a rectangular chip resistor, and a flexible wiring board that could be bent. As a result, the Pepper was born, introducing a small, thin, and reliable radio that could fit into the breast pocket of a shirt. It was a huge hit, with more than one million units sold in the series, and it also became the technological foundation for a variety of subsequent products. Furthermore, the technology was the starting point for Group’s avionics business which began by equipping radios in airline seats and now has evolved to full screen In-flight Entertainment Systems and Wi-Fi connectivity services. Today, the company is a world leading supplier of in-flight entertainment and connectivity (IFEC) solutions for the aviation industry.

Pepper R-012 was released at 7,800 yen, compared to the initial target of around 16,000 yen.

Astrova, the latest in-flight entertainment system from Panasonic Avionics Corporation

The pursuit of high goals drives the creation of distinctively unique value

Konosuke urged the engineering team, who were struggling to achieve both thinness and high sound quality, to deliver an authentic sound despite the product's thinness, encouraging them by saying, "The important thing is to satisfy radio listeners wherever they are." He himself even checked the audio quality four times. The efforts of component engineers throughout the company to achieve these ambitious goals resulted in a revolutionary product that pushed the limits of minimal weight, thickness, and overall dimensions.

Image stabilization technology is a standard feature of today's digital cameras. In fact, Panasonic invented this technology and was the world's first company to implement it. This invention was inspired by a discovery during a trip to Hawaii.

Around 1980, an engineer traveled to Hawaii with a colleague. While driving, the colleague tried to film the scenery with a large video camera he held on his shoulder. Observing the colleague's physical movement made to prevent images from blurring, the engineer noticed that it was a rotational movement at the waist and thought that a gyro sensor, which he was considering using in a car navigation system, could solve this problem. Back in Japan, he succeeded in miniaturizing gyro sensors, which were previously difficult to use inside a camera, and in developing an image stabilization mechanism and algorithm. In 1988, Panasonic released the world's first video camera with image stabilization. When showcased at an exhibition in the US, it amazed and impressed visitors. This technology was also highly regarded scientifically, with the original research paper being recognized as novel and unique at an academic conference. A patent was also filed, making Panasonic both in name and in fact the world's first manufacturer to install an image stabilizer in a camera.

PV-460, the world's first video camera with an image stabilizer (released in June 1988)

LUMIX DC-S9 full-frame mirrorless interchangeable lens system camera

Delivering highest-quality video recording, proud of supplying world's first image stabilization

Actually, video and still image stabilizers involve different principles. However, Panasonic engineers are proud to be part of the company that created the world's first image stabilization technology and are determined to live up to this reputation. Therefore, they developed image stabilization for the comfortable shooting of still images as well, aiming to provide the highest-quality shooting experience not only with video cameras but also with digital still cameras such as LUMIX.

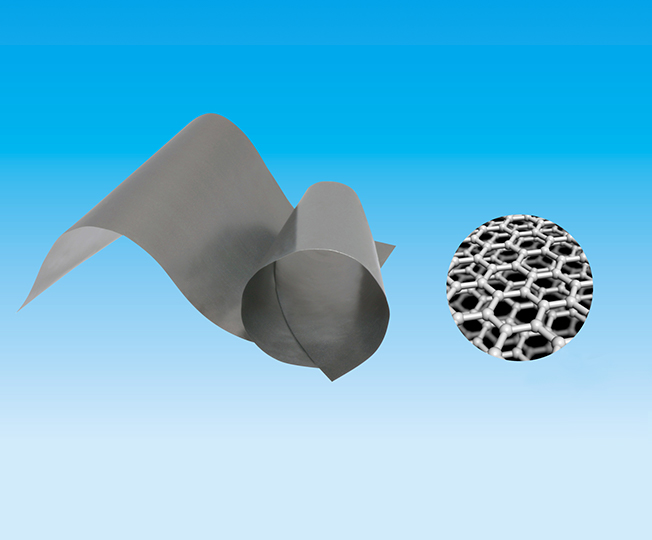

Countermeasures against heat are crucial for smartphones. High-performance CPUs installed in mobile devices, which have been miniaturized to the smallest possible size, produce high heat that requires measures to prevent functional decline. The Graphite Sheet significantly contributes to dissipating this heat.

PGS® Graphite Sheet

Right: The image of the Graphite Sheet crystal structure

After the discovery of conductive polymers,* a polymer research project team led by a national research institution was launched in 1981 within Matsushita Research Institute Tokyo, Inc. (at the time). Later, in 1983, crystalline graphite,** a metal-like material that efficiently conducts electricity and heat, was created. A commercialization project emerged from this basic research. While robust in the direction parallel to its surface, conventional crystalline graphite is weak in the direction perpendicular to its surface, decreasing its workability. Even as application development proceeded with difficulty due to these properties, a flexible type was then produced by accident. This was the moment that upset the conventional wisdom about graphite. This new crystalline graphite, combining high heat conductivity with flexibility, was formed into sheets that, in 1998, were used to dissipate heat in laptop computers. With the evolution of smartphones and electronic devices to make them more sophisticated, smaller, thinner, and lighter, the Graphite Sheet became an integral material for coping with heat, thus making the transition from a mere thermal diffusion material to an essential product material. This invention received the Ichimura Prize in Industry in 2010, the Okochi Memorial Prize for Production Technology in 2012, and the Commendation for Science and Technology by the Japanese Minister of Education, Culture, Sports, Science and Technology in 2014.

* An electricity-conducting plastic discovered by Dr. Hideki Shirakawa, who received the Nobel Prize in Chemistry 2000.

** A crystalline form of carbon consisting of stacked flat layers with a regular hexagonal lattice structure.

Fully committed to creating and commercializing useful products for the world

The Graphite Sheet is the fruit of Panasonic engineers' tenacious efforts, which enabled them to complete the entire process from basic research to application development and product commercialization over a long period of time. This enduring process could only be achieved by unwavering goals, the conviction to follow through with the project, and opportunities to benefit from trends . This is an outstanding example of new solution proposal and business incubation.

When it's used, hydrogen does not emit CO2, raising expectations for it as a next-generation energy source. The fuel cell generator is a system that generates electricity and heat by causing chemical reactions between hydrogen and oxygen. The well-known ENE FARM is a household fuel cell generator that Panasonic put on the market for the first time in the world.

Basic research into fuel cells was launched in the late 1950s, and research on polymer electrolyte fuel cells* began in 1991. Both projects were halted in midcourse due to the circumstances surrounding them. Nevertheless, as the adoption of the Kyoto Protocol** in 1997 rapidly raised the public's environmental awareness, Panasonic began research on household fuel cell generators under the slogan "From Energy Conservation to Energy Creation." Because this product development required a variety of technologies, in 2001, a group-wide team of engineers from different fields of expertise assembled to launch the Fuel Cell Generator Commercialization Project. The initial prototype could generate power for only 72 hours. Two years later, in 2004, Panasonic achieved power generation of 2,000 hours, and then spent three more years to eventually achieve 40,000 hours. Meanwhile, in 2005, a large-scale demonstration of the generator was conducted in the official residence of the Japanese Prime Minister, as well as in other houses. In 2008, Panasonic completed the technology development, which led in the next year to the release of the world's first household fuel cell generator under the name ENE FARM.

* Polymer electrolyte fuel cell: A fuel cell using a polymer membrane as its electrolyte. Panasonic uses this type of fuel cell for its effective use of heat.

** Kyoto Protocol: The international treaty adopted at the third session of the Conference of the Parties to the United Nations Framework Convention on Climate Change (COP3), held in Kyoto, for promoting international efforts to address global warming.

First ENE FARM household fuel cell generator (2009)

H2 KIBOU FIELD, a demonstration facility using pure hydrogen fuel cell generators (photographed in April 2022)

As a pioneering manufacturer of fuel cell generators, Panasonic endeavours continue

Since the release of ENE FARM, Panasonic have worked to promote further technological innovation, such as increasing the duration of power generation, downsizing, improving efficiency, and developing functions for disaster preparedness. Its cumulative production volume has exceeded 250,000 units in February 2024. In addition, Panasonic released pure hydrogen fuel cell generators to the general public in October 2021. This product leverages technology accumulated through ENE FARM, and it generates power by directly supplying hydrogen rather than extracting hydrogen from city gas. The Group is accelerating its efforts to make better use of hydrogen energy.

The nano-sized particulate ions enveloped in water, called nanoe, are far smaller than water vapor, and they are effective in suppressing bacteria, viruses, pollens, and molds, as well as in deodorization and beauty care.

In 1997, Panasonic launched research into nanoe, a unique technology for generating nanoe ions by applying high voltage to condensed water extracted from the atmosphere. A nanoe device was added to air purifiers for the first time in 2003, expanding the range of applications from consumer electronics to trains, cars, hospitals, hotels, and offices. By leveraging the power of water to dissolve contamination and odor, Panasonic has provided clean and comfortable spaces throughout the world. In 2021, Panasonic modified the counter electrode plate from the conventional four-needle shape to a dome shape that forms countless discharge points in a conical shape, thus completing the development of the new nanoe X device. This expanded the area for generating OH radicals,* achieving a 100-fold increase (to 48 trillion per second) in the number of OH radicals contained in an ion compared to the original nanoe. As one of Panasonic's core technologies, nanoe is still evolving.

* The source element exerting nanoe effects. The larger the number, the higher and quicker the expected effects.

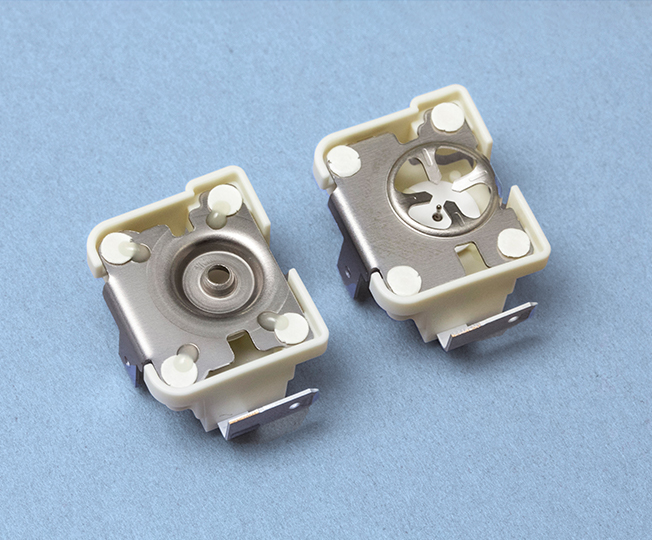

The new nanoe X device (left, dome-shaped counter electrode plate) and the previous nanoe X device (right, four-needle-shaped counter electrode plate)

Eolia 2024 High-Grade Model X Series

Believe in the power of technology and take on challenges from a long-term perspective

The following approach can lead to success: (1) analyze customer problems from a scientific perspective, think about what can be done with the power of technology, and find optimal solutions through testing and verification, (2) cross departmental boundaries and, in some cases, cooperate with external experts and university research institutes while making continued investments and persistent efforts from a long-term perspective, and (3) keep at it until you succeed.

The content in this website is accurate at the time of publication but may be subject to change without notice.

Please note therefore that these documents may not always contain the most up-to-date information.

Please note that German, Spanish and Chinese versions are machine translations, so the quality and accuracy may vary.