Feb 13, 2026

- Products & Solutions

- Stories

- Panasonic GREEN IMPACT

- Hydrogen Energy Solutions

- Panasonic HX

- Europe and CIS

- Business Solutions

In the face of unprecedented threat to our planet and its life-supporting ecosystems, the Panasonic GREEN IMPACT (PGI) initiative embodies the company’s efforts towards a more sustainable global environment, and ultimately a better life for all. All operating companies across the Panasonic Group are contributing to PGI’s ambitious plan to achieve a CO2 emissions reduction of over 300 million tons—around 1% of current total global emissions1—by 2050.

Panasonic Corporate R&D Division is playing a key role in this mission, along with related divisions within operating companies across the Group. Across myriad scientific fields, the division is busy innovating eco-friendly new technologies and business models that will contribute to the FUTURE IMPACT aspect of PGI that includes initiatives to expand the volume of “avoided emissions,” the CO2 emission reductions achieved outside of a company’s value chain.

Since the implementation of PGI in January 2022, Panasonic Corporate R&D Division has focused principally on the two spheres of carbon neutrality and circular economy, areas that align with PGI focus fields. However, the division is seeking to further bolster PGI initiatives ahead of the game, by stepping into the third R&D area of “Nature Positive,” the vision set out at the 2022 United Nations Biodiversity Conference (COP 15).

This vision of stepping into the new area of nature positive was announced by Tatsuo Ogawa, Executive Officer & Group CTO of Panasonic Holdings Corp., at the company’s campus in Osaka’s Kadoma district. It is a vision that tangibly resonates with Ogawa, who recounts that a budding awareness of sustainability and circularity came to him as a young boy spending time in the Japanese countryside.

Tatsuo Ogawa delivers a keynote speech conveying Panasonic’s vision of greener and more fulfilled living via technological innovation

Ogawa’s presentation opened the Panasonic Corporate R&D Technology Forum, an event at the Kadoma campus that showcased an array of future-focused innovations. Panasonic Corporate R&D Division’s contributions to this event demonstrated how realization of carbon neutrality and the circular economy remain the core focuses of Panasonic Holding’s future R&D roadmap, with these now joined by a new vision to step into the sphere of nature positive in the near future. The new technologies shown, Ogawa affirmed, have potential to shake present-day industries to their foundations.

Panasonic Holdings’ R&D activity spans the twin spheres of GX (Green Transformation) and CPS (Cyber Physical System) technologies. GX is a Japanese government-led initiative focused on the shift from fossil fuels to clean energy, while CPS is the Panasonic Group’s own conception of improving people’s everyday lives by merging physical and digital data-driven “cyber” realms. Ogawa announced that Panasonic plans to increase investment in these two areas by some 70% ahead of fiscal 2024.

Over at the Tech Forum’s exhibition area, R&D specialists from Panasonic Corporate R&D Division were on hand to show how their groundbreaking innovations may make significant contributions to carbon neutrality, the circular economy, and nature positive.

Seiji Kojima, Chief Researcher, Applied Materials Technology Center Technology Division, demonstrated Bio CO2 Transformation, a proprietary biochemical process that addresses the world’s growing need for foodstuffs while taking a circular approach to carbon neutrality. This technology is among the first tangible manifestations of Panasonic Holdings’ vision to contribute to the nature positive realm.

The photosynthesis-based process, which tests show can boost food crop yields by as much as 40.9% in the case of spinach, consists of two steps. First, atmospheric CO2 is transformed into plant growth-promoting biomolecules via the photosynthesis of cyanobacteria. Second, these biomolecules—when applied to the leaves of plants as a highly diluted spray—stimulate the crop’s photosynthesis-related metabolism, thereby enhancing yield. As Kojima explains, our planet provides a limitless, free-of-charge supply of core ingredient CO2, which may give Bio CO2 Transformation scope to help offset the rising cost of foodstuffs.

Seiji Kojima explains the intricacies of Bio CO2 Transformation, a proprietary biochemical process that addresses the world’s growing need for foodstuffs while taking a circular approach to carbon neutrality

The Bio CO2 Transformation process itself takes place within a very simple reactor. Under regular temperature and pressure conditions, engineered cyanobacteria secretes photosynthetically produced biomolecules in the presence of air and around 16 watts of illumination (natural light is also acceptable). No additional equipment or infrastructure investment is required on the part of farmers, and—in addition to promoting growth—the biomolecules also improve a crop’s resistance to disease.

Novitek is a plant growth-promoting liquid, containing biomolecules diluted by a factor of 1,000, that is simply sprayed onto the leaves of crops

Kojima’s experience with Bio CO2 Transformation speaks to the advantages of developing a technology under the aegis of a dynamic and multi-faceted enterprise such as the Panasonic Group. “When I first saw the growth-promoting effect of our CO2-derived biomolecules on spinach in the laboratory, I immediately envisioned the big picture of using atmospheric CO2 to enhance food production,” he recalls. “The question, however, was whether this effect would be relevant in actual agricultural settings, and whether production of these biomolecules could be scaled up to commercial levels in an economically feasible way.

Novitek’s effectiveness demonstrated on spinach crops: On the left, a single spraying increased yield by more than 40%

“This was a problem that could not be solved by the R&D team alone,” Kojima continues. “However, with the cooperation of group operating companies that have diverse customer contact points and business channels—something characteristic of Panasonic—we verified the crop yield enhancement via field trials, and established a manufacturing system for commercial use.”

Bio CO2 Transformation technology is planned to be commercialized as a biomolecule spray, under the brand name Novitek. Domestic Japanese sales are projected to begin as early as 2024.

Renewable energy, plus the balancing of energy provision and demand, are also key facets of Panasonic Holdings’ carbon neutral vision. This is demonstrated in perovskite PV, a next-generation solar panel that can be subtly incorporated into a building’s architecture in the form of windows, facade paneling, and more. Perovskite PV thus has the potential to supplant present-day solar panels with an alternative that forms part of, rather than intrudes upon, the aesthetics of towns and cities.

Yukihiro Kaneko demonstrates highly efficient perovskite PV solar cells that can be incorporated into a building’s design, as well as structures that cannot accommodate conventional solar panels

Moreover, as explained at the event by Yukihiro Kaneko, General Manager in Panasonic Holdings’ Applied Materials Technology Center, Technology Division, perovskite PV can also make a superior contribution towards the future of carbon neutrality. Kaneko, who was raised amid the rich natural beauty of Hokkaido in northern Japan, says he grew up wondering what he might do to help protect the environment. Through perovskite PV, this ambition has been fulfilled.

Panasonic Holdings Corporation has achieved one of the world’s highest conversion efficiency levels for a perovskite-based module of over 800 cm2 in size—17.9% as certified by a third party, which is almost equal to that of a conventional commercially available crystal silicon module. Perovskite PV’s flexibility of form, meanwhile, comes from a fabrication process that involves its photovoltaic cells being printed onto a glass substrate via familiar inkjet technology—a simpler method compared to standard solar panels.

August 2023 saw Panasonic announce that it has begun demonstration, and long-term testing, of Perovskite PV integrated into the architecture of a model house at Fujisawa Sustainable Smart Town (Fujisawa SST) in Japan’s Kanagawa Prefecture. Panasonic is a major proponent of Fujisawa SST which, as one of the world’s few smart cities, showcases sustainable future living in action.

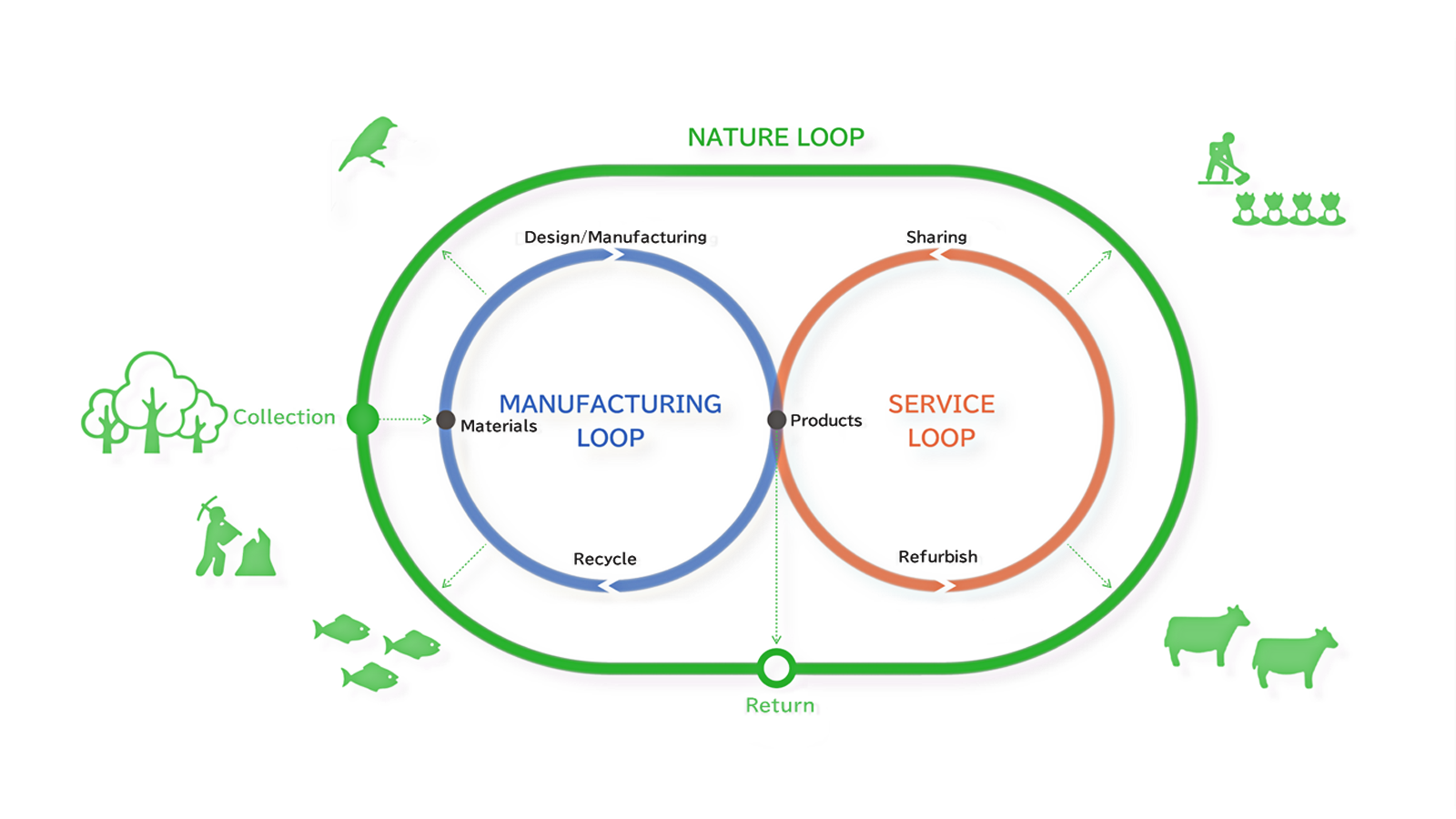

Panasonic Holdings’ approach to actualization of the circular economy is conceptualized as a three-looped process, in which a “manufacturing loop” (incorporating material sourcing, product design and manufacture, and recycling) and a “service loop” (operating in the customer sphere and encompassing sharing of products, and their repair and refurbishing) interact in the wider interest of our planet’s own “nature loop,” a third loop newly added to embody Panasonic Holding’s nature positive vision.

Circular economy model of production, manufacturing, and service development, now including an additional “nature loop” to illustrate the R&D vision of stepping into nature positive

Also showcased at the forum was a circular plastic substitute, named kinari, whose ability to take near-unlimited forms could make it a go-to material in the circular economy. In kinari, the oil-derived resin used in conventional plastic is—to the greatest extent possible—replaced with plant-based cellulose fiber that may be extracted from all kinds of waste materials, including used coffee grounds and timber felled in woodland preservation. The revolutionary material can be formulated to be both tougher and lighter than the increasingly problematic “real thing,” and also offers unrivaled flexibility as to the finishes it may be given—from sleekly modern to nature-reminiscent textures that some users have mistaken for real wood.

Lunchtime tableware used at a school in Fukuchiyama City, Kyoto Prefecture, is made from kinari containing extracts from surplus local trees

The circular model devised for kinari involves the material recycled by one of two methods—both presently under development—once it reaches the end of its lifespan. Material recycling will see kinari reconstituted via a low-emission process into fresh supplies of the same material, while biological recycling will be a process in which kinari is biodegraded into the earth with no negative environmental impact.

Panasonic Holdings recognizes that, while the environmental and social challenges we face now and in the future must be grasped at a global level, individual contributions towards goals such as circular economy and nature positive will be made at a very local level. “Local efforts that align with the biodiversity and lifestyles of individual regions will in concert form larger scale solutions,” envisages Ogawa. This mindset is evident in, for example, Panasonic working with a Kyoto Prefecture school to provide students with lunchtime tableware made from kinari that utilizes surplus timber from local woodland.

The company’s myriad efforts in the face of environmental and social challenges, both manmade and natural, together embody a conception of nature positive that Ogawa believes is ultimately about recognizing oneself as part of the natural world, rather than something distinct from it. This same awareness, he says, was another realization that came to him in the countryside as a youngster.

Similarly, Ogawa acknowledges that the goals aimed for by the Panasonic Group’s GREEN IMPACT initiative—and now Panasonic Holdings’ gradual expansion into nature positive—are ones too large for any single company to accomplish alone. To this end, he expressed hope that the Panasonic Corporate R&D Technology Forum might act as a catalyst for other likeminded businesses to partner with Panasonic in its planet and people-focused mission.

The content in this website is accurate at the time of publication but may be subject to change without notice.

Please note therefore that these documents may not always contain the most up-to-date information.

Please note that German, Spanish and Chinese versions are machine translations, so the quality and accuracy may vary.