Dec 25, 2025

- Products & Solutions

- Stories

- Technology

- AI & Robotics

- R&D

- Business Solutions

Oct 11, 2018

Products & Solutions / Press Releases

Panasonic's new PanaCIM-EE Gen2 realizes enhanced quality,

reduced costs and increased floor productivity.

Osaka, Japan - Panasonic Corporation announced today that the company will start accepting orders from the middle of October for PanaCIM-EE Gen2*1, a new integrated management software that enables control of the entire surface mount technology (SMT) floor. This software will be installed in factories in which electronic components are mounted on printed-circuit boards.

On production sites, demand for smart factory utilizing IoT and M2M technology has been increasing to realize mass customization while improving quality, productivity and cost reduction. In order to meet these needs, Panasonic proposed the industry's first integrated line management system, called iLNB, in October 2016. This system has been well received as the real-time operation status of the entire mounting line, composed of equipment from different manufacturers, can be centralized to one computer, and automatic model changeover can be executed.

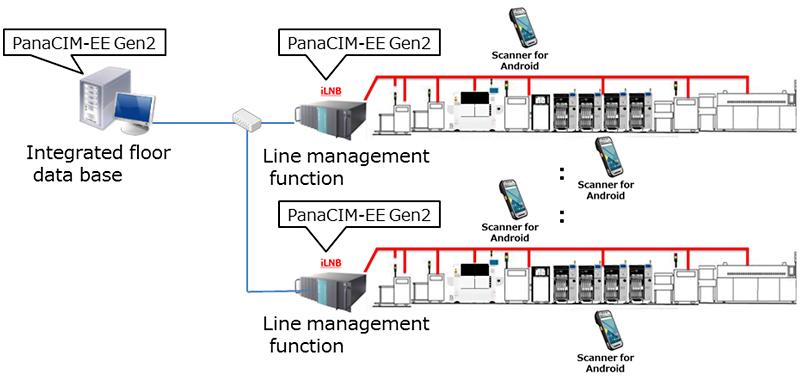

In order to integrate and manage this mounting line at the floor level, it is necessary to introduce a manufacturing execution system (MES) that tracks the status of each process and supports the operator. PanaCIM Gen2 boasts new functions added to the existing MES software PanaCIM-EE and in combination with iLNB this new software enables distributed control for each line including other company's equipment*2. In addition to collecting information and analyzing each line in real time, PanaCIM-EE Gen2 features integrated materials management and maintenance required by the floor level where multiple lines are set up, and realizes the optimal QCD (quality, cost and delivery) balance for the entire floor.

The versatility of the interface connected to the external system has also been improved. The new software is compatible with systems that are widely adopted at customers' sites, such as scanners using smartphones for Android™ *3 and multiple manufacturers' components verification systems, contributing to the reduction of installation cost.

Based on the manufacturing know-how cultivated over many years, Panasonic will continue to work toward the realization of Smart Factory which will bring various benefits to the entire factory into the future.

Panasonic Corporation is a worldwide leader in the development of diverse electronics technologies and solutions for customers in the consumer electronics, housing, automotive, and B2B businesses. Celebrating its 100th anniversary in 2018, the company has expanded globally and now operates 591 subsidiaries and 88 associated companies worldwide, recording consolidated net sales of 7.982 trillion yen for the year ended March 31, 2018. Committed to pursuing new value through innovation across divisional lines, the company uses its technologies to create a better life and a better world for its customers. To learn more about Panasonic:https://www.panasonic.com/global.

Panasonic Corporation

Tel: +81-(0)3-3574-5664

The content in this website is accurate at the time of publication but may be subject to change without notice.

Please note therefore that these documents may not always contain the most up-to-date information.

Please note that German, Spanish and Chinese versions are machine translations, so the quality and accuracy may vary.