Dec 25, 2025

- Products & Solutions

- Stories

- Technology

- AI & Robotics

- R&D

- Business Solutions

Apr 17, 2018

Products & Solutions / Press Releases

Panasonic's power choke coil for automotive use with the industry's highest resistance to vibration, contributes to more ECUs being placed within the engine itself and integration of mechanical and electronic in-vehicle components.

Osaka, Japan - Panasonic Corporation announced today that it has commercialized a high vibration acceleration-resistant (50 G or higher), surface-mounted type power choke coil [1] (10 mm square size) suitable for power circuits in automotive electronic control units (ECUs) employed in hybrid electric vehicles, electric vehicles, and gasoline-powered vehicles. The company will launch the new product by the end of this month.

With the growing demand for energy efficiency of eco-friendly cars and the need to comply with environmental regulations, computerization of cars has been rapidly expanding, and ECUs are being incorporated more frequently and on larger scales in cars. In addition, more ECUs are being placed within the engine itself, elevating integration of mechanical and electronic in-vehicle components [2]. This trend has created a need for automotive ECUs that can be installed in high-temperature environments that have more severe vibration conditions and support large current. Choke coils with high resistance to vibration and heat as well as support for large current are essential for removing noise and smoothing the power supply of power circuits that constitute automotive ECUs. The company is launching its surface-mounted type power choke coil for automotive use achieving the industry's highest(*1) resistivity of 50 G or higher vibration acceleration.

DC/DC converter circuits [3] and power circuits for high-performance ECUs incorporated in hybrid electric vehicles, electric vehicles, and gasoline-powered vehicles, and mechanical-electrical-integrated automotive ECU circuits

The placement of automotive ECUs has been changing from the engine compartment to the engine itself, which requires coils used in automotive ECUs to have high resistance to vibration. Conventional products structurally have a low self-resonant frequency [4] around 2,000 Hz and have an issue with vibration resistance. By utilizing the company's metal composite material [5] using its unique metal magnetic material and own winding and molding technologies, Panasonic created a coil with a high self-resonant frequency of 3,000 Hz or higher leading to the industry's highest resistance to vibration acceleration of 50 G or higher, contributing to more vibration-resistant automotive ECUs.

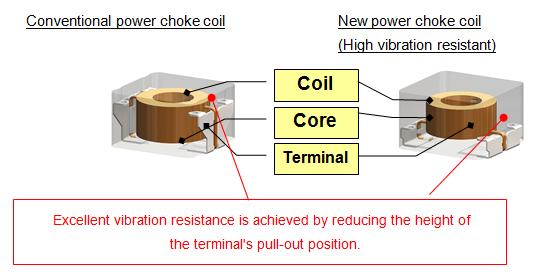

The conventional automotive ECU board mounting process requires anti-vibration measures, such as anchoring components with bonding agents (adhesives), to make the ECU resistant to vibration. The height of the developed power choke coil's terminal pull-out position is reduced to half that of the company's conventional product through the adoption of the company's unique winding and molding technologies, allowing its placement near the mounting board to achieve excellent vibration resistance. This has made conventional anti-vibration measures unnecessary, allowing the streamlining of the production process.

Coils used in automotive ECUs are required to be heat-resistant and support high current, in addition to being highly resistant to vibration. Previously, coils with high resistance to vibration acceleration of 30 G or higher had an issue of not being able to support large current due to their low profile and small size. The developed power choke coil achieves a vibration acceleration resistance of 50 G or higher while also having excellent heat resistance and supporting large current, through the adoption of the company's unique metal composite material, thereby contributing to the placement of automotive ECUs in the engine itself.

| Vibration acceleration | 50G (490 m/s²) |

|---|---|

| Frequency | 5 - 2000 Hz |

| Amplitude | 5 mm max. |

| Vibration directions, number of times (Time) | X, Y, Z directions, 108 times (equivalent to 100 h) |

| Temperature | 150°C (including product's self-heating when energized) |

| Series | Case size (L×W)mm | Inductance[6](*1) | DC resistance[7] 20°C | Rated current (*2) |

|---|---|---|---|---|

| PCC-M1050MS | 10.9 x 10.0 | 0.68uH | 1.66 mΩ | 27A |

| Series | Case size (L×W)mm | Inductance[6](*1) | DC resistance[7] 20°C | Rated current(*2) |

|---|---|---|---|---|

| PCC-M08**MS | 8.5 x 8.0 | 2.5~100uH | 7.4~302 mΩ | 12~5A |

| PCC-M10**MS | 10.9 x 10.0 | 0.33~100uH | 1.0~208 mΩ | 33~2A |

Panasonic Corporation is a worldwide leader in the development of diverse electronics technologies and solutions for customers in the consumer electronics, housing, automotive, and B2B businesses. Celebrating its 100th anniversary in 2018, the company has expanded globally and now operates 495 subsidiaries and 91 associated companies worldwide, recording consolidated net sales of 7.343 trillion yen for the year ended March 31, 2017. Committed to pursuing new value through innovation across divisional lines, the company uses its technologies to create a better life and a better world for its customers. To learn more about Panasonic:

http://www.panasonic.com/global

Panasonic Corporation

Tel: +81-(0)3-3574-5664 Fax: +81-(0)3-3574-5699

The content in this website is accurate at the time of publication but may be subject to change without notice.

Please note therefore that these documents may not always contain the most up-to-date information.

Please note that German, Spanish and Chinese versions are machine translations, so the quality and accuracy may vary.