Feb 24, 2026

- Products & Solutions

- Press Releases

Oct 12, 2020

Products & Solutions / Press Releases

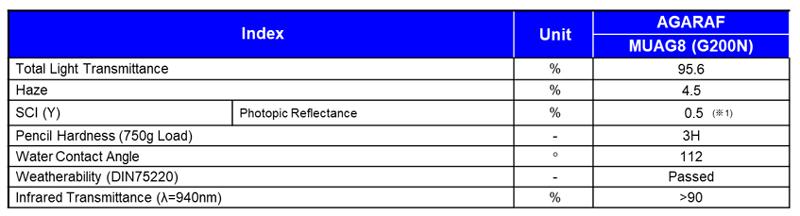

- The company has achieved a film with a low reflectance of 0.5% through a wet process with excellent cost performance for the first time in the industry*

- The film boasts excellent weatherability conforming to the DIN (Deutsche Industrie Norm) Standards and high infrared transmittance

Osaka, Japan – Panasonic Corporation announced today that its Industrial Solutions Company has commercialized an anti-glare type [1] anti-reflection film for automotive displays. A wet process with excellent cost performance was adopted to develop the low reflection film with the model number MUAG8 (G200N). The company has started shipping samples and will start mass production in April 2021.

Progress is being made to upgrade automotive displays, including center information displays and side displays, by addressing the need for larger screens, higher resolution, higher definition, odd form varieties, and improved operability. Under such circumstances, the displays are required to provide high visibility to allow drivers to instantly obtain information for ensuring safe and comfortable driving, creating strong demand for reducing reflection from the displays.

To reduce the reflection from the automotive displays, their outermost surfaces require anti-reflection properties. A method of laminating a film on screens is suited to achieve such anti-reflection. Such method can easily address the need for larger screens and odd form varieties and also prevents screen glass from shattering upon impact. Therefore, a wet process [2] for producing anti-reflection films is adopted to develop the product.

However, there is a problem whereby it is difficult for conventional wet processes to concurrently ensure that produced films have good anti-reflection characteristics and high durability during actual use, while the processes have excellent cost performance advantages, including a short production lead time. Panasonic has achieved the low reflection characteristics of the new film with the reflectance reduced to 0.5% or lower by employing its unique resin design, hard coating material design, and nano-coating technologies.

Moreover, the product has high weatherability that meets the DIN Standards [3] related to deterioration under harsh use environments. In addition, Panasonic's original design technology of optical materials achieves the new film with high infrared transmittance, which is effective when infrared sensors are installed as part of a driver monitoring system incorporated into the periphery of a display. This allows the film to transmit a greater amount of infrared rays. When the film can ensure the amount of infrared rays required for the sensors to detect incoming rays, the film can be attached to the surface of the display with the inside sensors fully covered.

This developed product will be exhibited at the SID Vehicle Displays Online 2020 to be held on October 14 and 15, 2020.(URL:https://www.vehicledisplay.org/)

Automotive displays (including instrument cluster panels), such as center information displays, side displays, and automotive displays equipped with driver monitoring systems on the periphery

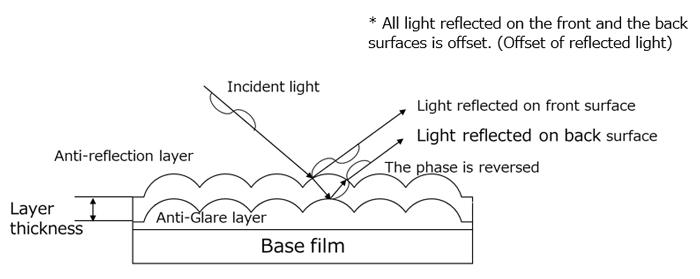

Light incident to an anti-reflection layer reflects on both the front and the back surfaces of the layer. Optimizing the refractive index and thickness of the layer can reverse the phase of the light reflected on the back surface, which can offset all light reflected on the front and the back surfaces to achieve a low reflectivity layer. Panasonic uses its unique resin design and hard coating material design technologies to laminate a combination of multiple high and low refractive-index layers, and further forms them into a film deposited onto a base film by using its unique nano-coating technology. Light reflected from the formed film is reduced by the reflection offset, thereby allowing the company to achieve a low reflectance of 0.5% or lower through a wet process for the first time in the industry.

Under the harsh environments of a car cabin, anti-reflection films are exposed to significant issues related to film deterioration, including discoloration and film peeling. The developed product underwent weatherability testing that conforms to DIN75220 (Z-in 1) [4] that requires repeat exposure of UV irradiation under high temperatures and condensed humidity under low temperatures. After that, the company performed a cross-hatch adhesion test [5] to check the adhesion of the product under harsher conditions and verified that there was no film peeling.

Panasonic's original design technology of optical materials achieves the new film with high infrared transmittance, which is effective when infrared sensors are installed as a part of a driver monitoring system incorporated into the periphery of a display. This allows the film to transmit a greater amount of infrared rays. When the film can ensure the amount of infrared rays required for the sensors to detect incoming rays, the film can be attached to the surface of the display with the inside sensors fully covered. This eliminates the need for additional processing such as perforating areas of the film through which sensors receive infrared rays, thereby contributing to the reduction of process steps and the improvement of design quality.

Electronic Materials, Industrial Solutions Company, Panasonic Corporation

https://industrial.panasonic.com/cuif/ww/contact-us?field_contact_group=2343&field_contact_lineup=3253&ad=press20201012

Panasonic Corporation is a worldwide leader in the development of diverse electronics technologies and solutions for customers in the consumer electronics, housing, automotive, and B2B businesses. The company, which celebrated its 100th anniversary in 2018, has expanded globally and now operates 528 subsidiaries and 72 associated companies worldwide, recording consolidated net sales of 7.49 trillion yen for the year ended March 31, 2020. Committed to pursuing new value through innovation across divisional lines, the company uses its technologies to create a better life and a better world for its customers. To learn more about Panasonic: https://www.panasonic.com/global.

The content in this website is accurate at the time of publication but may be subject to change without notice.

Please note therefore that these documents may not always contain the most up-to-date information.

Please note that German, Spanish and Chinese versions are machine translations, so the quality and accuracy may vary.