In 2018, Panasonic is celebrating its 100th anniversary. The first product that the founder, Konosuke Matsushita, introduced to the world a century ago in 1918 was the "Attachment Plug." Then came the "2 Lighting Cluster" in 1920. These wiring devices are the roots of the company, and Panasonic's wiring devices to this day boast a high market share in Japan and remain a key pillar of business for Panasonic. Panasonic's wiring device business has continued to safely deliver a comfortable, convenient lifestyle with light and has supported social development. This article introduces the 100-year journey and the future vision of Panasonic's wiring device business.

- The inaugural product was a tour de force in an age where there were no wall outlets.

- Wiring devices have evolved with the times.

- Panasonic's wiring devices spread across the world.

- The world of Panasonic's "wiring devices" continues to expand.

- Column: Tsu Factory, the birthplace of Panasonic's latest wiring devices

The inaugural product was a tour de force in an age where there were no wall outlets.

"Attachment Plug," a fruit of improvements made day and night by the founder, Konosuke Matsushita

Back in 1918, Japanese homes did not have wall outlets. The only source of electricity in homes was the light bulb socket dangling from the ceiling. But at night, the plug would be used for the light bulb, so it was very difficult to use any other electronic product.

The "Attachment Plug" was a connector that was used to connect the cables of electronic products to the light bulb socket. These already existed back then, but the 23-year old founder realized cost cuttings by reusing the sockets of used light bulbs. The newly developed Attachment Plugs that were of better quality and cheaper by 30-50% were very well received.

This photograph was taken a year after the company was established. Back row, from left to right: Konosuke Matsushita, his brother-in-law Toshio Iue, and his wife Mumeno Matsushita.

The Attachment Plug then evolved into the innovative "2 Lighting Cluster," which transformed a single light bulb socket into 2 power sources. This, too, was highly appraised as it allowed users to keep the light on in the room while using the iron or the kotatsu (small table with an electric heater underneath). These 2 wiring devices paved the way for Panasonic's growth and success.

1931. The "2 Lighting Cluster" appeared in an advertisement when homes did not have any wall outlets. There is a light bulb in one socket, while a kotatsu is plugged into the other.

This small company, which started with just 3 people, had grown to 20 employees by year-end. By the way, Panasonic currently has approximately 274,000 employees (as of end of March 2018) around the world.

Panasonic's inaugural product was the "Attachment Plug." Without changing the basic structure, 100,000 units of this product are still being manufactured and sold annually to this day, 100 years later. They are being used by festival stalls and shipping boats for lighting.

Wiring devices have evolved with the times.

Creating safe, high-quality products while placing people at the heart of design.

From around 1955, when Japan began to see the light at the end of its restoration efforts after World War II, the "Three Sacred Treasures" of post war Japan - home appliances such as TVs, refrigerators, and washing machines - rapidly became a part of people's lives. With the electrification of society, needs for high quality wiring devices increased. And to meet these needs, Panasonic continued to offer highly versatile, safe, and user-friendly products.

Wiring devices - Development journey

100 years later, a business that started with 1 wiring device is still evolving into a diverse range of products that includes switches, outlets, and sensors.

Transitions in home wiring devices in Japan.

Now let us take this opportunity to look back at how wiring devices were used in Japanese homes.

Living in the early 20th century - The age of electric light devices

The manufacturing of wiring devices in Japan began in the early 20th century, and electricity gradually became widespread in Japanese homes. Back then, construction to install switches and outlets was rare. Homes were equipped with light bulb sockets, but the wiring was exposed. And to use electronic products other than light bulbs, "Attachment Plugs" and "2 Lighting Clusters" were necessary.

Living in the 1940s - The age of the first home electrification boom

Although consumer electronics were on the increase, wiring in homes could not keep apace. As a result, sockets and electrical circuits were so overloaded that there were electrical accidents across the country. To resolve this issue, power companies, the wiring device industry, and wiring device manufacturers joined forces to launch the "Proper Wiring Movement" in 1958. Panasonic developed the embedded wiring equipment that allowed users to attach up to 3 switches and outlets to each box.

This is when the wiring started to be embedded in walls rather than remain exposed.

Living in the 1960s - The age of the second home electrification boom

The capacity of switches increased from 10A to 15A, and in order to improve the safety of outlets, large-sized modules, the "Full Color Embedded Wiring Equipment" was born. The development of the "Quick-Connect Terminal Type Full Color Wiring Device" allowed users to access electricity by simply plugging in and also reduced the need for construction. Moreover, by developing a Full Color Module that fulfilled JIS standards, Panasonic contributed to the development of the entire industry.

In 1966, Panasonic launched a campaign that proposed a new lifestyle with "2 lights and 3 outlets in one room" coined as the "Electricity 1, 2, 3 Movement."

After 1975, a diverse range of high performance switches were developed, including the Mood Switch that matched the interior décor, "Hotaru (Firefly) Switch," which had a small light that lit up in the dark, and the Timer Switch.

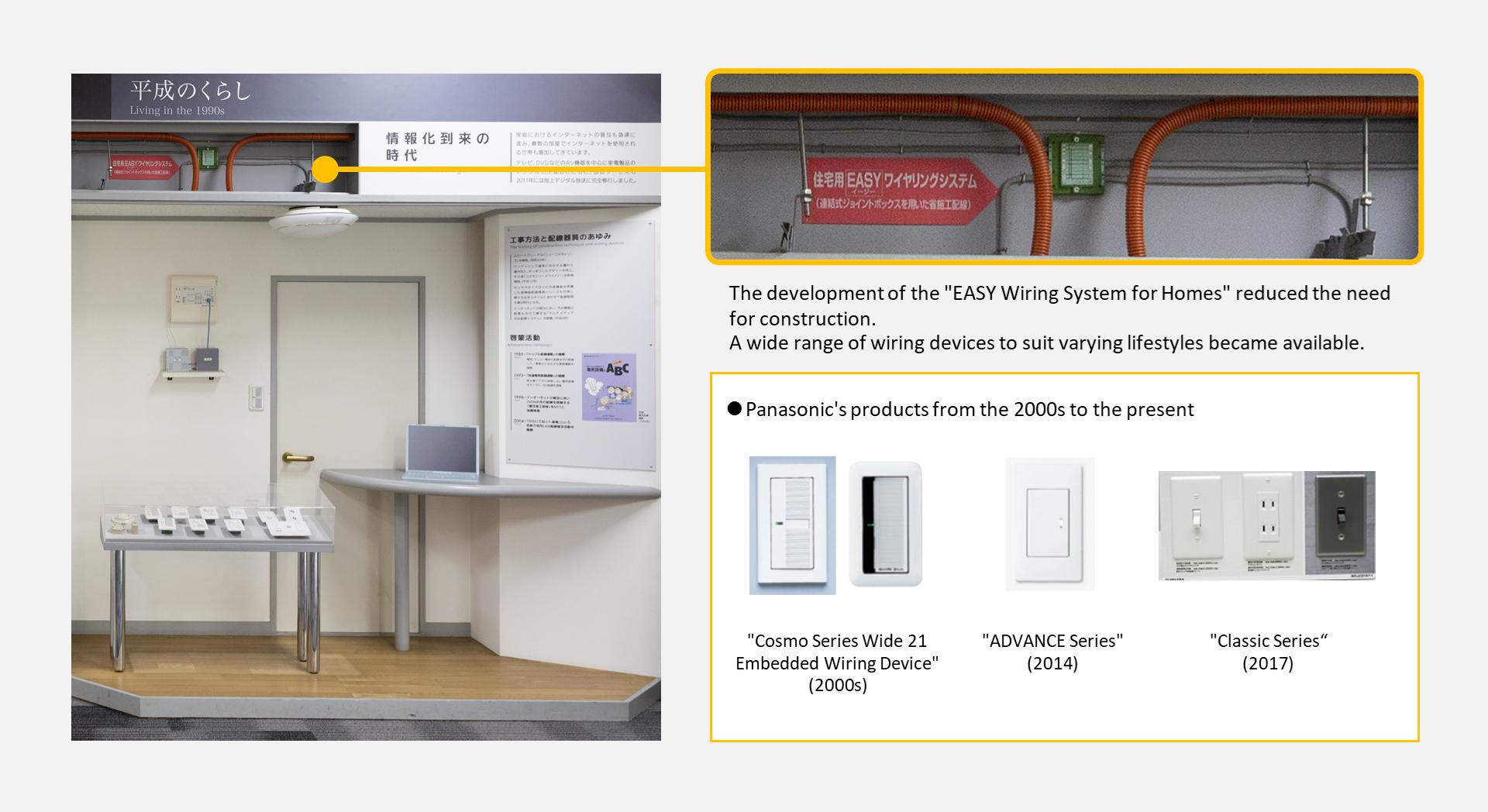

Living in the 1990s - The information age

In 1985, Panasonic developed the "New Cosmo Series Embedded Wiring Device." Panasonic brought to life both excellent operability that responded to a single push as well as a streamlined design. And in 2000, Panasonic launched the "Cosmo Series Wide 21 Embedded Wiring Device," which had a wider operating surface making it easier to use for children and the elderly. Even in 2018, Panasonic is continuing to make improvements to its switches.

With respect to wiring construction, in 1997, as Internet became more and more widespread, Panasonic introduced the "Multimedia Port," which pre-installed IT wiring. Panasonic also added new products equipped with advanced technology such as sensors and timers to its high performance wiring devices, giving people a wide range of wiring devices to suit varying lifestyles.

In addition to traditional push switches, Panasonic "ADVANCED Series" added switches that can be turned ON/OFF simply by touching it and dimmed by trailing one's finger across it. As of 2018, lights can be controlled via smartphones and tablets (only when the user is at home). Moreover, by working together with the energy management system, "Smart HEMS," which makes energy in the home visible and intelligently controls various equipment and the air conditioner, lights may be controlled to save energy (*).

In the future, the lighting will work together with smart speakers to enable users to easily control the lighting with voice commands (to be made available in FY2018).

In recent years, to respond to the needs of architects, Panasonic has launched a retro tumbler switch series. Panasonic's wiring device business, which has continued for 100 years, continues to diversify.

* Working with the "Smart HEMS":

If the energy usage in the home surpasses the preset daily target, the brightness of the lights connected to the touch LED dimmer switches will automatically be adjusted to save energy.

Panasonic's wiring devices spread across the world.

Global toll of "local production, local consumption and total optimization"

Panasonic's wiring devices were mainly exported in the 1980s, but in the 1990s, Panasonic began establishing its sales arm in each country/region and began developing and manufacturing products mainly for China and Asia. Post 2000, Panasonic rapidly expanded its global reach through, for example, M&A. As of 2018, Panasonic's wiring devices are being manufactured in 9 countries, 11 locations, and are being sold in more than 60 countries around the world, mainly in Asia. Panasonic boasts the second largest market share in the world, the first largest share in Asia. And by 2020, Panasonic is aiming to have the largest share in the world (according to Panasonic research).

The circumstances surrounding manufacturing in each country are different even if you take one single switch. Of course there are differences in standards, but functions and design also vary. Panasonic's wiring devices business focuses on local production, local consumption, meaning designing products that reflect the preferences of people who live in that country or region and the situation in which they would use that product. And depending on the situation, some parts will be exported to other countries to respond flexibly to needs and realize total optimization.

For example, in China, just like consumer electronics, trends in wiring devices are changing dramatically. Amid this environment, in 2016 Panasonic launched the "Gecai Series" which featured the world's first push type switch. Panasonic brought to life a safe, well-designed product at a reasonable price worthy of becoming the new market standard, which would blend into lifestyles in China. In 2016, Panasonic won the Good Design Award and the iF Design Award in 2017.

In the Middle East, just like the consumer electronics Panasonic had developed in the past for this market, local consumers tended to prefer more glamorous designs, gold plated products being one of their favorites.

In Turkey, Panasonic manufactures products for Turkey as well as adjacent countries. Panasonic offers a wide range of products from reasonable products to luxurious ones.

The world of Panasonic's "wiring devices" continues to expand.

From serving as a switch to an advanced device connected to the entire house.

100 years ago, Panasonic's wiring device business began with the "Attachment Plug". Keeping apace with the evolution of lifestyles, Panasonic has continued to offer switches, outlets, as well as distribution boards, chimes, switchboxes, etc. and to propose an enriched lifestyle with safe, reassuring lighting. Through the ages, Panasonic has continued to hone its technologies in wiring devices, lighting control, electrical circuits, alarms, disaster-prevention systems, and piping equipment and once entering the 21st century, Panasonic expanded its reach to the world of energy management, developing products that create, store, and save energy in the entire home.

Panasonic will continue to deliver safe, easy to use, high quality products.

Column: Tsu Factory, the birthplace of Panasonic's latest wiring devices

Panasonic Eco Solutions Company's Tsu Factory located in Tsu City, Mie Prefecture manufactures direct descendants of Panasonic's inaugural wiring devices. There are over 1,000 employees, and each year the factory produces 85 million devices. From product design, parts manufacturing, to assembly, Panasonic consistently ensures high quality while remaining conscious of the environment. The wiring device manufacturing wing manufactures products around the clock, and the logistics within the factory have been automated.

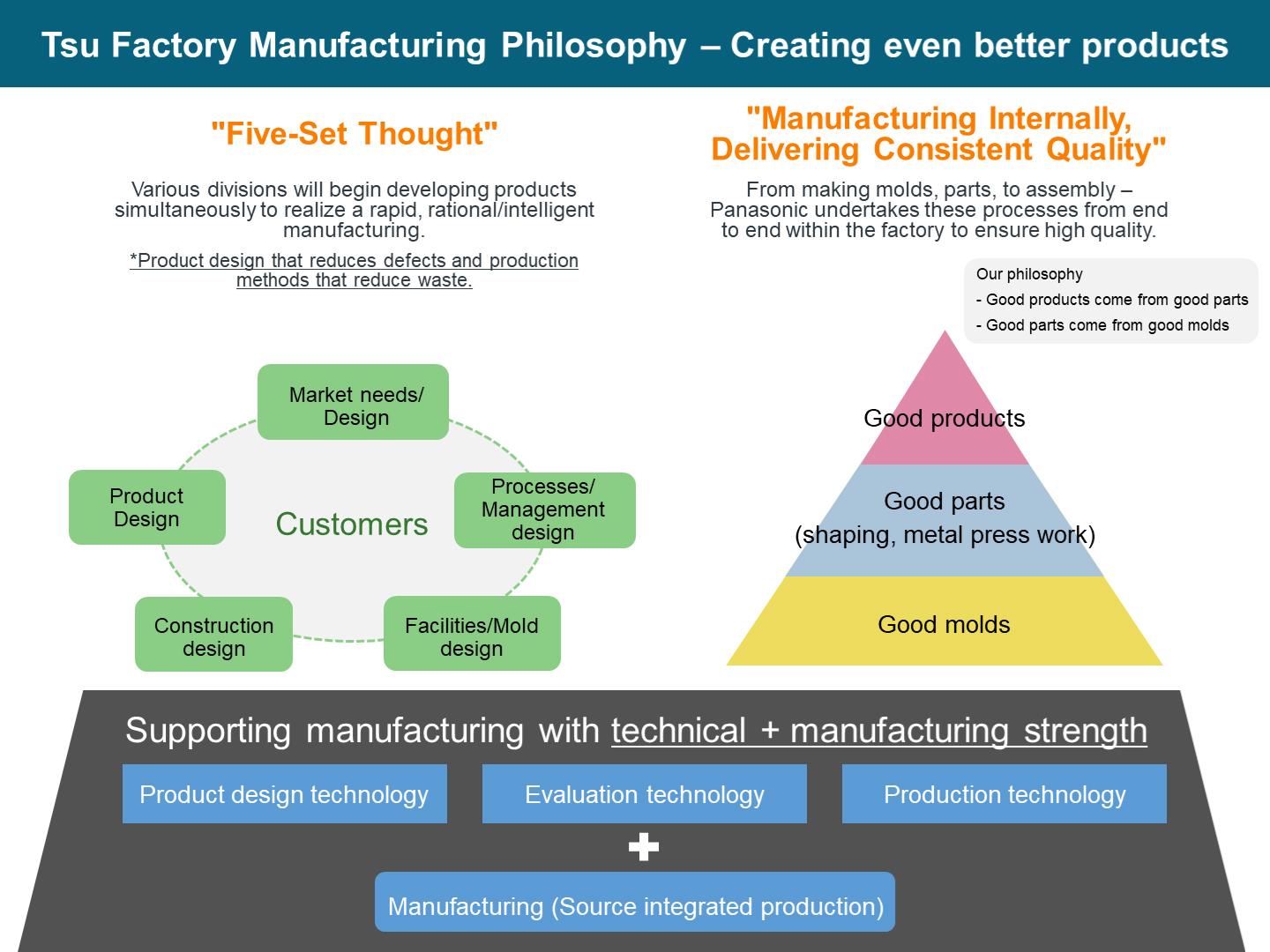

Tsu Factory's manufacturing philosophy

In order to deliver extremely safe, durable wiring devices that blend into people's daily lives and are hardly noticed, the factory holds dear the following manufacturing principles.

"Five-Set Thought"

This is a philosophy unique to Panasonic. It means that from early on various divisions develop products simultaneously to realize a rapid, rational/intelligent manufacturing.

"Manufacturing Internally, Delivering Consistent Quality"

From making molds, parts, to assembly - Panasonic undertakes these processes from end to end within the factory to ensure high quality.

Automation within the factory. The manufactured parts are transported by the automatic delivery machine to the next process.

Role of Tsu Factory as a mother factory

In order to realize smooth production of wiring devices in global manufacturing plants, the Tsu Factory serves as the mother factory. Engineers from the Tsu Factory visit global manufacturing plants regularly to pass on manufacturing skills and concepts that local markets require.

# # #

- Disclaimer:

- We would like to note that Panasonic Newsroom is not a place to address personal Customer Service issues. Even though this is not the forum, Panasonic is always eager to resolve your concerns. Our local customer services contacts can be found at Global Support or you can see our list of Social Media Accounts to find the right channel for your queries and concerns.