Panasonic has developed the SG-P series safety door switches that enable workers to see the open/closed state of doors of the entire production equipment at a glance. The products will be released in October 2020. They will increase the safety of workers during maintenance at production sites, as well as reduce machine downtime, thereby improving the operating rate.

Osaka, Japan - Panasonic Corporation announced today that has developed the SG-P series safety door switches designed to increase the safety of workers by letting them see the open/closed state of doors of entire production equipment at a glance. The products will be released in October 2020.

Until now, human workers and machines have worked separately at production sites. But in recent years, the environment in which people and machines work in cooperation while recognizing each other is increasing, which is further raising safety awareness on factory floors.

However, switches that can easily disable safety functions are still used at production sites, which is one of the factors that cause serious accidents to workers. By detecting only the paired actuator, it prevents the intentional disabling of interlocks, which is a mechanism that deactivates machine operations when certain conditions are not met and enhances the safety of workers during maintenance.

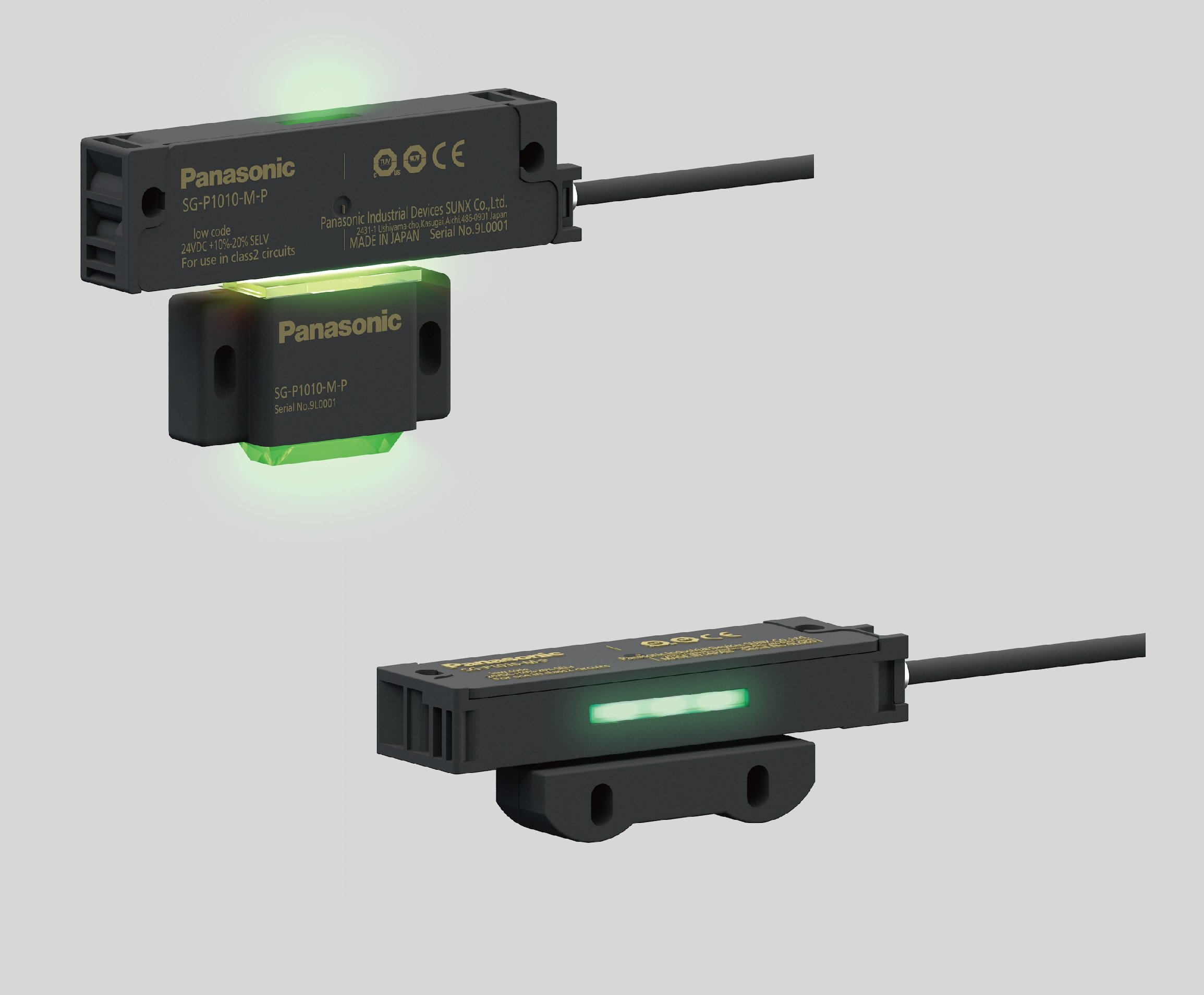

There was another problem. Machines could not be operated immediately when using switches with small indicators, because it takes time to check the open/closed state of the doors of the entire production equipment. To address this problem, Panasonic has equipped the newly developed switches with a large and bright indicator and configured the actuators to illuminate, enabling workers to swiftly identify open doors. This will reduce machine downtime and improve the operating rate.

Features

- Prevention of the intentional disabling of interlocks

- Large and bright indicators show the open/closed state of the doors of the entire equipment.

- The parent-child structure saves wiring, allowing up to 30 units to be connected in series.

Product features

Prevention of the intentional disabling of interlocks

During the maintenance at production sites, intentionally disabling interlocks when opening equipment doors can be a major cause of accidents because there is a risk that another person may operate the machine without noticing the worker. Panasonic's new safety door switches prevent intentional disabling by adopting an RFID system (*1) that detects only the actuator paired with the switch. Its compliance with the coded levels specified in ISO 14119 (*2) increases the safety of workers.

(*1) System for reading and writing individual actuator information by using weak radio waves

(*2) General requirements for the design and selection of interlocking devices associated with the safety guards of machines.Large and bright indicators show the open/closed state of the doors of the entire equipment.

The newly developed safety door switches are equipped with a large and bright indicator despite being compact enough to be fitted in a 30-mm square aluminum frame. Open doors are indicated with bright red lighting, whereas other doors linked to the open doors are indicated with green flashing lights to show their unsafe state. Conventional switches with a small indicator were not easy to see from the outside when mounted on the inside of doors, making it difficult for workers to identify open doors. However, the actuator of these products is configured to also illuminate, enabling the checking of the state of the switch even from the outside and consequently, the swift identification of open doors. This reduces machine downtime, improving the operating rate.

The parent-child structure saves wiring, allowing up to 30 units to be connected in series.

Up to 29 sub switches, which are child devices, can be connected to one standard switch, which performs as a parent device, allowing up to 30 units to be connected in series. Only the parent device outputs, which eliminates the need for wiring used for output from linked child devices, thereby saving wiring required for mounting on equipment.

Suitable applications

Production equipment in electric and electronic component industries, etc.

Sales area

Global

Basic specifications

- Compliant standards:

International standards: ISO 13849-1 (Category 4, PLe), IEC 61508-1 to 7 (SIL3), IEC 62061 (SIL3), IEC 60947-5-3, ISO 14119

Japan: JIS B 9705-1, JIS C 0508 1 to 7, JIS B 9961, JIS C 8201-5-2, JIS B 9710

Europe (EU): EN 60947-5-3, EN 300 330, EN 301 489-1 - Power supply voltage: 24 V DC

- Control output: PNP/NPN Transistor open collector 2 outputs

- Protective structure: IP65

- Outer dimensions:

Compact type: Switch W88×H15×D25 mm, Actuator W56×H15×D13 mm

Visible type: Switch W88×H15×D25 mm, Actuator W52×H15×D32 mm

Part numbers

- Compact type

Standard: Low level coded (PNP output) SG-P1010-M-P, (NPN output) SG-P1010-M-N

Standard: High level coded (PNP output) SG-P2010-M-P, (NPN output) SG-P2010-M-N

Sub: Low level coded SG-P1010-S

Sub: High level coded SG-P2010-S - Visible type

Standard: Low level coded (PNP output) SG-P1020-M-P, (NPN output) SG-P1020-M-N

Standard: High level coded (PNP output) SG-P2020-M-P, (NPN output) SG-P2020-M-N

Sub: Low level coded SG-P1020-S

Sub: High level coded SG-P2020-S

# # #

- Disclaimer:

- We would like to note that Panasonic Newsroom is not a place to address personal Customer Service issues. Even though this is not the forum, Panasonic is always eager to resolve your concerns. Our local customer services contacts can be found at Global Support or you can see our list of Social Media Accounts to find the right channel for your queries and concerns.

![[Video] Panasonic Stories in 60 Sec: Panasonic HX](http://news.panasonic.com/uploads/tmg_block_page/cover_image/18401/60sec-panasonic-hx.jpg)

![[Video] Panasonic Stories in 60 Sec: Robot Control Platform Robo Sync](http://news.panasonic.com/uploads/tmg_block_page/cover_image/18349/60sec-robo-sync.jpg)