The Yamatogawa Route, measuring approximately 10 km in total length, fully opened in March 2020, connecting between Sakai City and Matsubara City in Osaka. Panasonic constructed the tunnel ventilation facilities for this route. Panasonic delivered more products than any other project of this kind in its history, including 78 large jet fans, each as big as an airliner's jet engine, as well as 64 electrostatic precipitators and 14 exhaust fans. In the following, the members in charge of the project at Hanshin Expressway Company and Panasonic talk about the project.

Summary

- In March 2020, the long-awaited Yamatogawa Route, a new extension of the loop expressway, fully opened, and it is expected to mitigate traffic congestions and improve distribution efficiency in the Kansai metropolitan area of Japan.

- For this route, which is almost entirely underground tunnels, Panasonic designed and constructed the tunnel ventilation facilities, and delivered 78 large jet fans, 64 electrostatic precipitators and 14 exhaust fans.

- Panasonic's tunnel ventilation business is unfamiliar to most people, but it dates back more than a half century and Panasonic boasts a solid reputation in this field in Japan.

The new route of Osaka's loop expressway fully opened and became the main artery in the east-west direction.

About 19 years ago, in August 2001, the "Osaka Urban Renaissance Loop Route ," was formulated as a city revitalization project. As the name implies, this project aimed to create an expressway network that goes around half of Osaka Prefecture and eliminates the "missing link."

The urban expressway network established in the central area of Osaka Prefecture forms the core of the metropolitan highway network from which various routes extend outwards radially. Thus, flows of traffic concentrate on the Loop, resulting in chronic traffic congestion. In order to reduce traffic volumes on the loop expressway, it was decided to construct and connect a new route to expand Osaka's loop expressway network to approximately 60 km in total length.

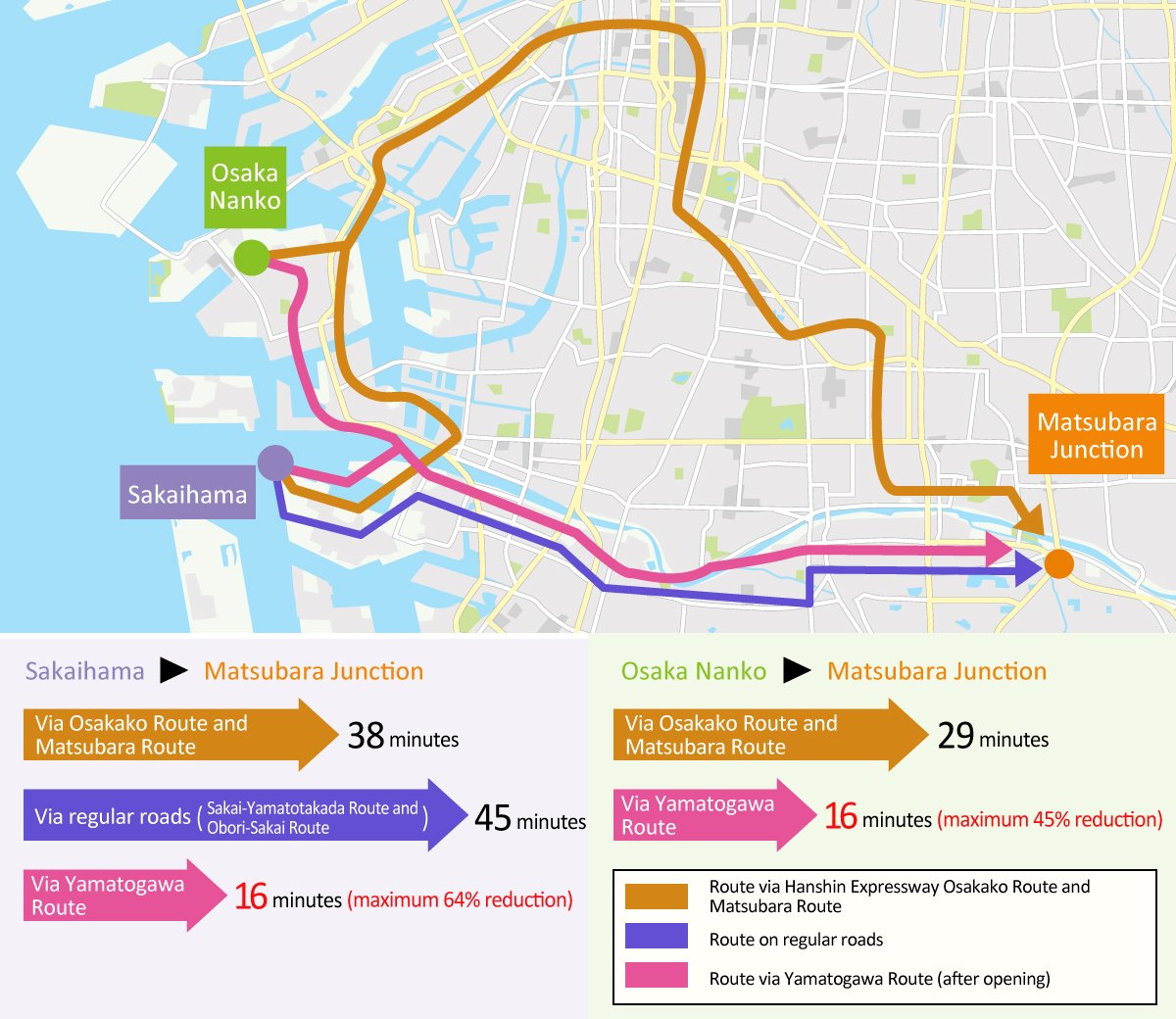

On March 29, 2020, at 16:00, the Hanshin Expressway Route 6 Yamatogawa Route fully opened. The Yamatogawa Route connects between Sanpo Junction in Sakai City and Matsubara Junction in Matsubara City. It stretches 9.7 km in the east-west direction and runs next to the Yamato River (Yamatogawa), which flows alongside the boundary between Osaka City and Sakai City. Completion of the Yamatogawa Route was long awaited, because east-west traffic concentrated on certain arterial roads, causing constant traffic congestion on community roads, although the area has a good railway network in the north-south direction formed by West Japan Railway, Nankai Electric Railway and Osaka Metro. An average driving time from Sakaihama in Sakai City to Matsubara Junction on regular road is presently about 45 minutes, but opening of the Yamatogawa Route decreases the traveling time significantly to about 1/3, or approximately 16 minutes.

Improved accessibility between the coastal area and inland area is expected to reduce traveling times.

Since the Yamatogawa Route connects to the Nishi-Meihan Expressway, Osaka's coastal area and inland area become easily accessible from Nara Prefecture. Previously, it was necessary to detour significantly in the north-south direction when driving on the expressway from the Matsubara Junction to Osaka City. Many manufacturers are located along the regular roads running along the Nishi-Meihan Expressway, so the opening of the Yamatogawa Route is expected to improve the distribution efficiency. Furthermore, the new route serves as an alternative road in the event of a disaster.

Almost the entirety of the Yamatogawa Route is in underground tunnels. That's where Panasonic's technologies were utilized. Panasonic delivered the air ventilation system essential for the tunnels on the Yamatogawa Route, such as jet fans, electrostatic precipitators and exhaust fans. Some of the readers may be surprised to know that Panasonic was deeply involved in such a major infrastructure project. The following introduces some of Panasonic's environmental engineering business activities that are unfamiliar to many people.

Essential life-saving system for tunnels

Panasonic launched its tunnel ventilation business 52 years ago, in 1968, when the company name was Matsushita Electrical Industrial Co., Ltd. In that year, the company delivered, for the first time, jet fans to the Kurikara Tunnel located at the prefectural boundary between Toyama and Ishikawa. So, Panasonic already has more than a half century of history in this business field. About 10 years later, in 1979, Panasonic delivered electrostatic precipitators to the Tsuruga Tunnel on the Hokuriku Expressway for the first time. In 2004, Panasonic delivered a ventilation system for the long Hai Van Tunnel in Vietnam. By participating in major tunnel construction projects, Panasonic established a solid reputation in this business field.

Panasonic Environmental Systems & Engineering Co., Ltd. is now in charge of the tunnel ventilation business. The predecessor of this company was the former Ventilation Engineering Co., Ltd., which was spun off from the Engineering & Service Department in the Blower Business Division of the former Matsushita Seiko Co., Ltd. in 1976. The company changed its name to the current name in 2008. Panasonic Environmental Systems & Engineering proposes solutions and offers technical support pertaining primarily to water, air, soil and energy, such as tunnel ventilation systems, wastewater treatment systems, ventilation systems for agricultural and livestock farming applications, and soil and groundwater cleanup systems.

As Mr. Toshiaki Iwata at Panasonic Environmental Systems & Engineering explains, "Panasonic is widely known as a home appliance company, but the company also boasts a long history and successful track record of developing tunnel ventilation systems such as jet fans and electrostatic precipitators." In fact, Panasonic has delivered approximately 2,000 jet fan units, more than any other company in Japan. The company also has the largest market share for electrostatic precipitators in Japan. Panasonic was the first company in Japan to develop electrostatic precipitators.

Toshiaki Iwata

Group Leader

Road Environment EU Sales Group

Environmental Solutions Business Group

Panasonic Environmental Systems & Engineering Co., Ltd.

If you don't know what a jet fan is like, imagine a "huge electric fan" installed in a tunnel. It resembles a jet engine on an airliner. A jet fan controls the air flow in a tunnel.

An exhaust fan is installed in a ventilation station. The contaminated air sucked in by the exhaust fan enters the electrostatic precipitator, where the particulate matter contained in vehicle exhaust gas is removed from the air. The precipitator electrically captures particulates and discharges clean air. The electrostatic precipitator is mounted on the side of the ventilation station facing the tunnel. The clean discharged air is released to the atmosphere by the large exhaust fan through the above-ground exhaust stack. This is how a tunnel ventilation system works.

The tunnel ventilation project for the Yamatogawa Route was the largest project of this kind in the history of Hanshin Expressway Company. Mr. Kazuhiro Ajihara at Hanshin Expressway Company explains how important the ventilation system is in a tunnel.

"The Yamatogawa Route runs under densely populated urban areas. The newly installed system is called a centralized exhaust type longitudinal ventilation system, which effectively utilizes the flow of air created by moving vehicles and contributes to the preservation of the surrounding environment. This system uses jet fans to compensate for the fluctuation of traffic volume. Even though today's vehicle emission regulations are very stringent and vehicle exhaust gas is cleaner than before, measures to protect the environment are still necessary. For the Yamatogawa Route, ventilation stations were constructed at five locations, where the installed electrostatic precipitators suck in the polluted air in the tunnel and clean it for further protection of the environment.

Kazuhiro Ajihara

Section Manager

Facility Section, Sakai Construction Department, Construction Management Headquarters

Hanshin Expressway Company Limited

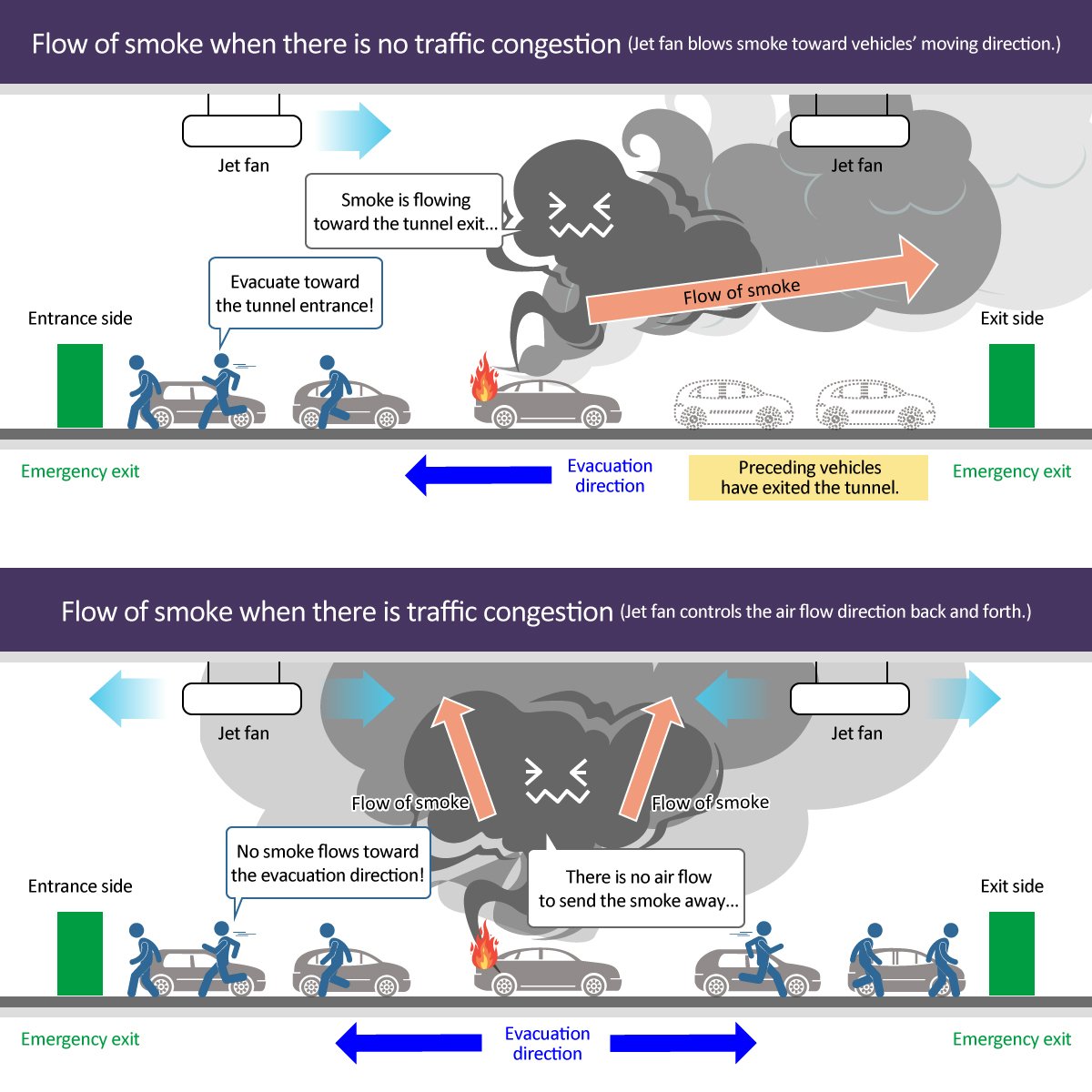

It is also imperative to consider the risk generated by a possible breakout of fire inside the tunnel. Therefore, it was decided to enable the tunnel ventilation system on the Yamatogawa Route to control the flow of smoke generated by a fire in the tunnel according to traffic conditions. For example, if there are people near the fire source, the jet fans control the spreading of smoke to provide a safer evacuation environment."

In the event of a fire, the ventilation system controls the flow of smoke according to traffic conditions to provide a better evacuation environment.

Panasonic Environmental Systems & Engineering delivered 78 jet fans, 64 electrostatic precipitators and 14 exhaust fans to the Yamatogawa Route. That was the largest tunnel ventilation facility construction order that Panasonic had ever received. The order included not only the manufacture of the equipment but also the design and construction of the entire tunnel ventilation facilities for the Yamatogawa Route.

Panasonic won the bid in 2014. This big project took six calendar years to complete. Mr. Iwata recalls, "For the preparation of our proposal, members in the main departments and sections, such as the Sales Department, Design Department, Production Department and Construction Department, gathered and brainstormed repeatedly in order to brush up the contents of the proposal. Hanshin Expressway Company comprehensively evaluated our proposal, including the cost and engineering aspect."

Weight reduction technology was maximized.

Panasonic made great engineering efforts relentlessly. The newly developed short and lightweight jet fan is especially noteworthy. The purchase specification specified a width of 4.25 m, but Panasonic further reduced the width to 2.5 m. The weight was also reduced from 2.0 tons to 1.5 tons, a reduction of about 25%. Tunnel No. 3, the longest tunnel on the Yamatogawa Route, is installed with 56 units of this new short-length jet fan.

"The jet fan was developed with the focus on economical operation and maintenance ease to meet the request of Hanshin Expressway Company. It was not difficult to reduce the length of the unit body, but because decreasing the unit body length would result in a shorter silencer length, the noise level would increase. Therefore, we began by reviewing sound absorbing materials and blade shapes. Then, we successfully shortened the unit body while keeping the noise below the reference level and ensuring the specified air flowrate and the strength of the fan unit.

"Our company is a long-established company in the industry and had accumulated knowhow. That was a big plus. We also know all about capturing customers' needs, which the Panasonic Group is very good at, and our company is more flexible and agile than other companies. Those are also our company's strengths. We began developing the new jet fan after we received the order. We never ease up on our efforts even after receiving orders," said Mr. Iwata.

Vehicle exhaust gas is sucked by the exhaust fan and particulates are removed by the electrostatic precipitator.

"The high-performance, short-length jet fan minimized the number of post-installed anchor bolts used in additional construction, thus resulting in enhanced reliability. The electrostatic precipitator offers improved energy-saving performance. We appreciate Panasonic's considerations for the reduction of power consumption," said Mr. Ajihara. Since infrastructure is put to the real test after it is placed in service, reliability and durability are very crucial. Mr. Ajihara continues, "Once the new route opens, traffic conditions will change. We look forward to Panasonic's continued proposals on operation improvements in the future."

To this comment, Mr. Iwata responded, "The word, 'Engineering,' in our company name denotes our belief that associations with customers continue from beginning to end, including the maintenance in between." Various new road construction plans will be executed across Japan in the future, and demand for the replacement of aged systems will grow accordingly. Fueled by the demand increase, Panasonic strives to boost sales of tunnel ventilation systems and equipment to \5 billion or more in fiscal year 2025. Panasonic continues to support the livelihoods of people although its achievements in this business field are generally invisible to ordinary people.

- Reproduced from the website "Mirai-kotohajime," by courtesy of Nikkei Business Publications, Inc.

# # #

- Disclaimer:

- We would like to note that Panasonic Newsroom is not a place to address personal Customer Service issues. Even though this is not the forum, Panasonic is always eager to resolve your concerns. Our local customer services contacts can be found at Global Support or you can see our list of Social Media Accounts to find the right channel for your queries and concerns.

Related Links

Related News

- The Tall Order of Developing a "100-Year Community": Where Panasonic's First Smart Town Is at 5 Years into That (Feb 17, 2020)

- Sustainable Solar Power Solution on a Remote Japanese Island Creates an Affluent Life in the Present with Eye on 2050 (Jan 30, 2020)

- Rejuvenating a Provincial City with EVs and Solar Power: An Ingenious Energy Cycling Idea in Motion (Dec 26, 2019)