In recognition of the contribution that resource efficiency can make to decarbonization, together with the need to reduce consumption of the planet’s finite natural resources, Panasonic introduced a Group-wide “Circular Economy (CE) Policy.” Under this policy, the Group is taking a three-pronged approach to CE: maximizing product lifetimes through innovative design, extended servicing, and enhanced recycling; minimizing the use of materials while extending the useful life of recycled and renewable materials; and collaborating with customers and partners to establish circular business operations.

The second area within the booth focused on the systems and services that Panasonic Group is introducing to promote the most efficient use of material resources along the product lifecycle as it transitions toward a circular business model. Exhibits were organized under three themes: Plastic Reduction, Resources Recrafted, and Resources Recycled.

Plastic Reduction introduced the Group’s efforts to reduce the use of new plastic materials in home appliances—from washing machines using components made from recycled plastic to the MultiShape modular personal care system that reduces resource consumption by 60 percent.

Resources Recrafted demonstrated how Panasonic Group is taking back TVs and washing machines with initial failure in Japan and using a rigorous refurbishment process to give them a second life and promote responsible reuse of products that would normally become waste.

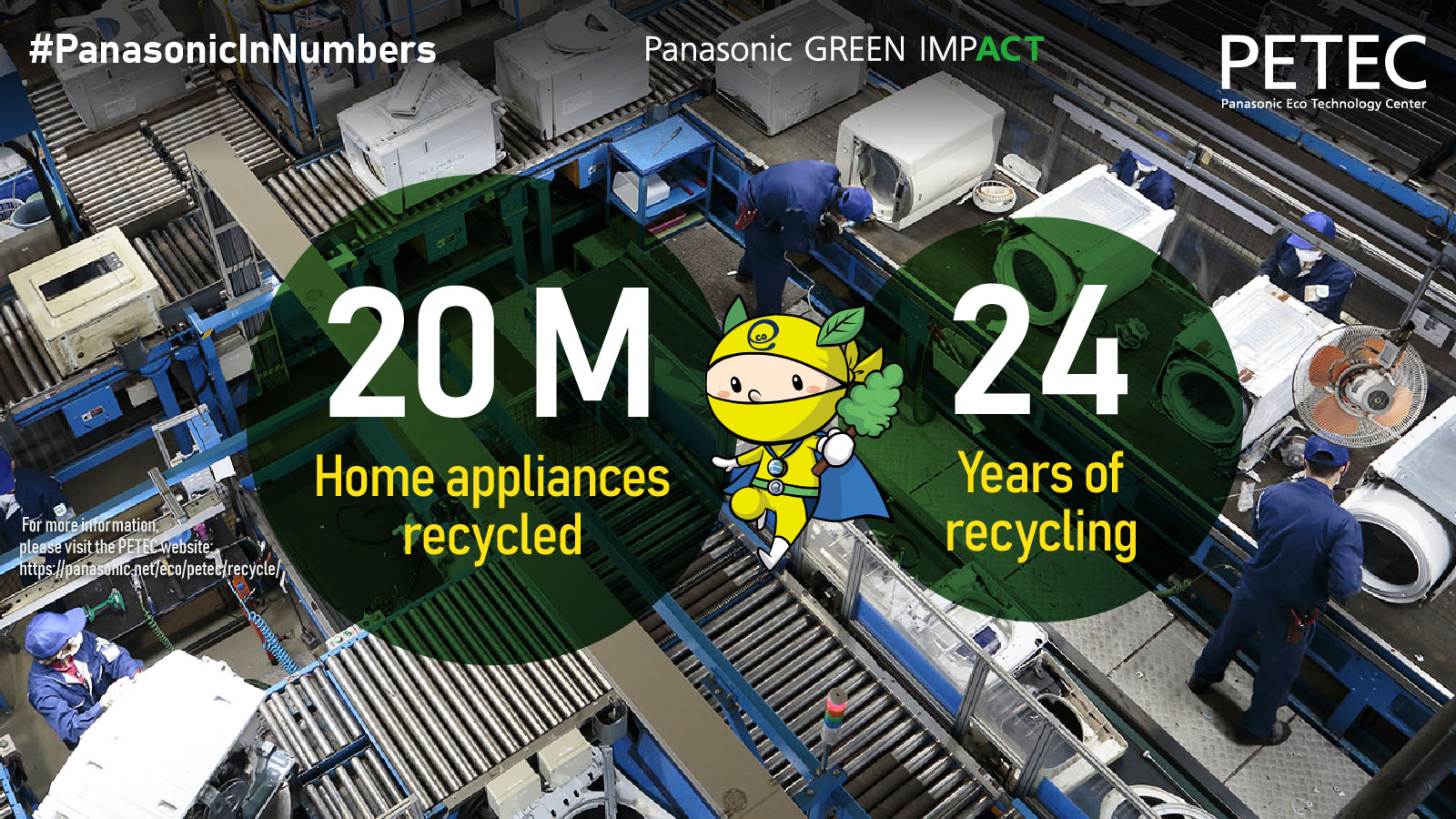

Resources Recycled explained Panasonic Group’s closed-loop model for plastic recycling, which recovers plastics from end-of-life appliances, uses a proprietary process to refine them, and then transforms them into tech-grade polypropylene (PP) plastic pellets that can be reused in new appliances. The area also introduced the role being played by AI-guided robots in the disassembly and recycling of old air conditioners—a technology that can be applied to the recycling of every appliance in the near future.

“At CES and our Panasonic booth, we wanted to use the products and solutions we offer to tell a compelling story about what Panasonic is doing so that visitors would be able to see how seriously we take decarbonization and carbon neutrality—how it’s just not talk, and that we are actively promoting this transformation process right now,” said Markus. Panasonic has been leveraging its product design expertise to develop products that reflect society’s shift away from a “throw-away culture” to what the Group refers to as a “use forever culture.”

Panasonic also demonstrated how it is applying its manufacturing expertise and strict quality assurance capability to the recycling of electronic devices to establish a product circulation scheme. Panasonic is building a system that closes the resource loop, from manufacturing to refurbishment and recycling of materials, based on the concept of “From Product to Product.”

“The booth displayed practical examples demonstrating how we are changing our business, and what we mean by ‘Create Today. Enrich Tomorrow.’ I think visitors were able to clearly grasp Panasonic’s transformation process, the solutions we are offering, and how these changes have the potential to make their lives more sustainable,” said Markus.