Panasonic encourages its customers and employees to live more sustainably and take part in initiatives that help the Earth. Earlier this year, the Group collaborated with One Tree Planted on a program that kicked off at CES 2023 in January and lasted until Earth Day, April 22. For every social media post tagging Panasonic and using the hashtag #PlantItForward, a tree was planted on lands within Clear Creek Watershed, an area severely impacted by the 2018 Carr Fires of California. A tree would also be planted if one explored the CES website, collected four badges, and shared them on social media with the hashtag. In total, 63,810 trees were planted.

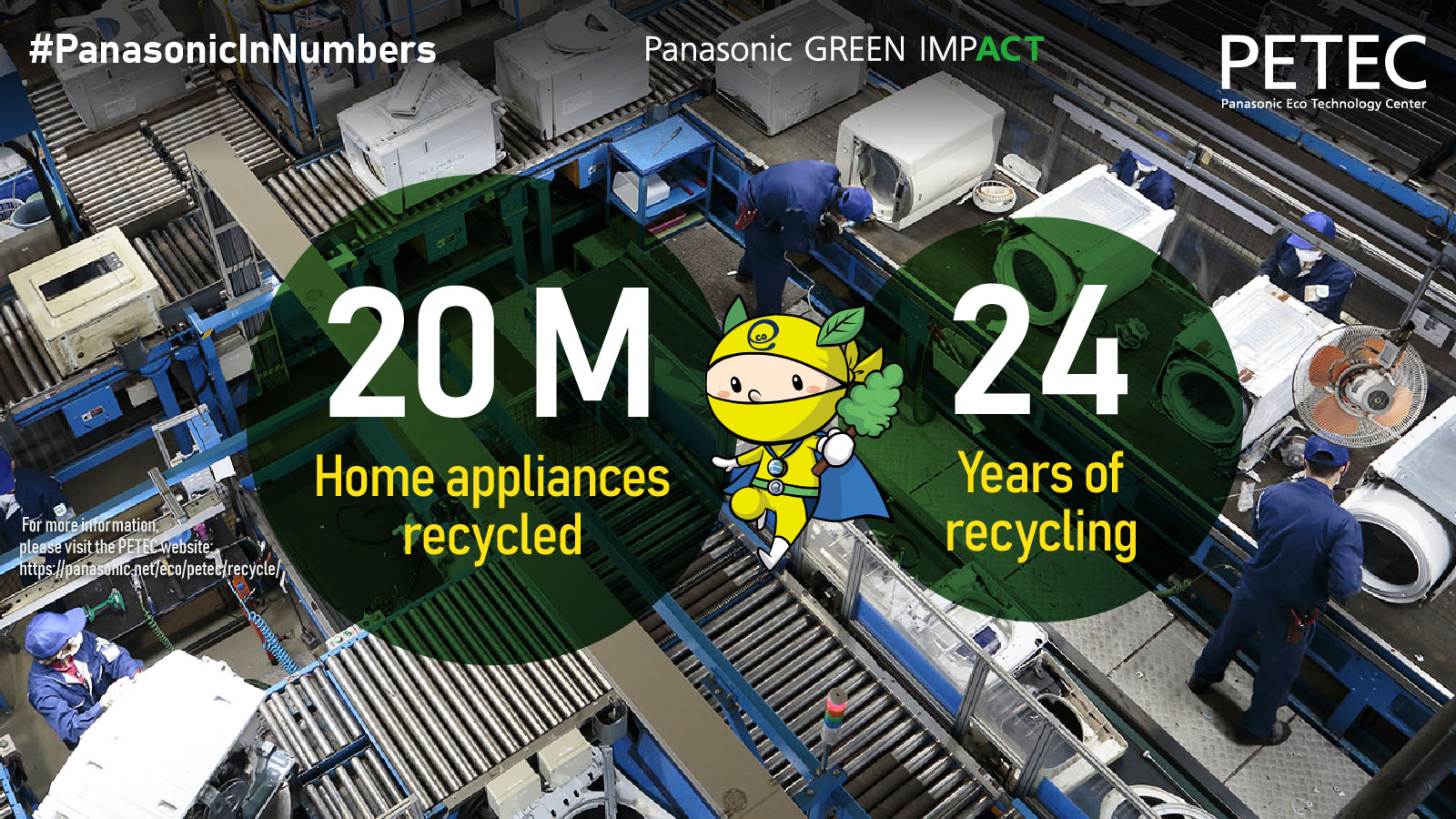

Panasonic is now preparing for CES 2024, and sustainability will be a major theme at the Panasonic booth. The Group also plans to use the event to discuss related themes such as the circular economy and better recycling.

Individual employees are also making changes to promote more sustainable lifestyles. In Newark, many Panasonic workers are doing away with paper and plastic cups and bringing their own reusable mugs. The HQ building of Panasonic North America is also conveniently located across from the local train station, so many employees have stopped driving to work and begun taking the train instead.

Murphy herself always carries a reusable bag for shopping and silicone straws that she can use at restaurants instead of the typical plastic straw. “When you make a lot of small changes, things that people can easily incorporate into their lives, those will build up and have a great impact.”