Feb 24, 2026

- Products & Solutions

- Press Releases

Jan 27, 2022

Products & Solutions / Press Releases

Osaka, Japan - Panasonic Corporation today announced that it has developed a technology for the mass production of far-infrared aspherical lenses suitable for improving the performance of cameras and sensors. These lenses are made of chalcogenide glass having excellent transmission characteristics in the far-infrared. In addition to realizing low-cost (approx. half compared to the company’s conventional method) by newly developed glass molding method and mold processing technology, Panasonic is now able to offer a variety of lenses such as diffractive lens, the world's first* highly hermetic frame-integrated lens without using adhesive (leak detection accuracy of less than 1x10-9 Pa・m3/sec in helium leak test). The company is now accepting prototype orders. By realizing mass production of low-cost and high-quality far-infrared aspherical lenses, the company will contribute to the spread and higher performance of far-infrared sensor modules.

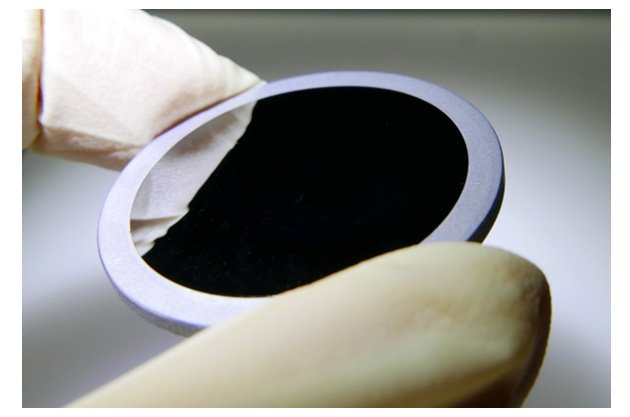

Frame-integrated lens (φ30 mm)

In recent years, amid increasing awareness of environmental protection, far-infrared sensors are playing an important role in energy management by heat detection or heat monitoring. In the automotive field, the increasing demand for autonomous driving technology has led to the spread of such sensors for their ability to detect distant people and animals at night, when ordinary visible light cameras cannot. Under these circumstances, far-infrared sensors are becoming more pixel-rich and lower price and the lenses used for theses sensors are also required to have higher added value.

On the other hand, low-cost silicon that has been commonly used as the lens material for far-infrared sensors are not suitable for high pixel counts due to its low transmittance, so germanium spherical lenses having high transmittance are widely used as the number of pixels increases. However, as the pixel count increases further, the effect of aberration caused by a spherical lens becomes more pronounced. To reduce this effect, combination of many spherical lenses and an aspherical lens will be required, which leads to increase in cost and size.

To resolve this problem, Panasonic has developed a new technology for the low-cost production of high-performance aspherical lenses suitable for far-infrared optical systems, based on the glass molding technology the company cultivated through the production of visible light aspherical lenses for cameras.

By utilizing this technology, Panasonic will contribute to the enhancement of far-infrared module performance through prototyping and mass production of the lenses that meet the requirements of customers who manufacture and sell various far-infrared sensors and cameras.

This development is realized by the following technologies.

Conventional glass molding requires grinding and polishing of the glass material as a pre-processing step before molding. In general, glass materials are cut from glass ingots to a predetermined size and then grinded to an approximate lens shape. Therefore, the process not only causes the disposal of a large amount of material, but also requires a long processing time including polishing, resulting in high costs. In addition, as chalcogenide glass is more expensive than conventional visible light glass and very easily cracked and scratched, the disposal and yield ratio in these processes affect the cost.

To resolve this problem, Panasonic has newly developed a pre-processing technology without grinding and polishing processes, thereby significantly reducing the time and cost of conventional pre-processing. As a result, the price of the lens is reduced to approximately half compared to those made by the conventional method.

Chalcogenide glass is difficult to mold stably because of the large change of viscosity caused by temperature change during molding. To solve this problem, a customized mold made from a new material that moderates thermal fluctuations was newly developed. Since this mold processing technology has enabled the use of conventional molding equipment for visible light glass and achieving high yield ratio, Panasonic is able to offer high quality and low-cost chalcogenide lenses.

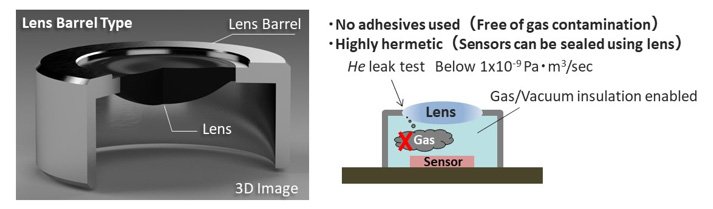

Chalcogenide glass is very easy to crack, so the edge of the lens is easy to chip during assembly into the lens barrel. To solve this problem, Panasonic realized for the first time in the world the manufacture of frame-integrated lens to prevent chipping on the edge of the lens which contacts the lens barrel by establishing a unique manufacturing method applying insert molding. The newly developed insert molding technology does not need any adhesive, so there are no side effects caused by unnecessary degassing. The integrally molded shape can meet a variety of requirements, from a frame shape to a simple barrel shape.

In addition, the contact area between the lens and the frame is possible to become high hermetic (leak detection accuracy of less than 1x10-9 Pa・m3/sec in a helium leak test). The high hermeticity between the lens and the frame enables gas sealing together with the far-infrared sensor placed inside. Therefore, reduction of thermal effects and improvement of transmittance are realized by internal insulation and coverless of sensor. As a result, it is possible to contribute to higher performance of the sensor.

Highly hermetic barrel-integrated lenses

The production of far-infrared aspherical lenses using this technology is considered to be carried out at Yamagata Factory of the Optical Device Business Unit, Lifestyle Updates Business Division of Panasonic Corp. and Panasonic Industrial Devices Nitto Co.

Panasonic will expand sales of these high-performance and low-cost far-infrared aspherical lenses in the future and contribute to the environment through its far-infrared lens molding technology.

Panasonic Corporation Technology Office

crdpress@ml.jp.panasonic.com

Panasonic Corporation is a global leader developing innovative technologies and solutions for wide-ranging applications in the consumer electronics, housing, automotive, and B2B sectors. The company, which celebrated its 100th anniversary in 2018, operates 522 subsidiaries and 69 associated companies worldwide and reported consolidated net sales of 6,698.8 billion yen for the year ended March 31, 2021. Committed to pursuing new value through collaborative innovation, the company uses its technologies to create a better life and a better world for customers. Learn more about Panasonic: https://www.panasonic.com/global.

The content in this website is accurate at the time of publication but may be subject to change without notice.

Please note therefore that these documents may not always contain the most up-to-date information.

Please note that German, Spanish and Chinese versions are machine translations, so the quality and accuracy may vary.