Feb 13, 2026

- Products & Solutions

- Stories

- Panasonic GREEN IMPACT

- Hydrogen Energy Solutions

- Panasonic HX

- Europe and CIS

- Business Solutions

Mar 02, 2022

Products & Solutions / Press Releases

The new series of systems will realize factories that autonomously update themselves to enable immediate response to customer demands and supply changes

Stable production can be achieved through autonomous control of the 5Ms of manufacturing

Osaka, Japan - Panasonic Smart Factory Solutions Co., Ltd. (to become Panasonic Connect Co, Ltd. in April 2022*1) announced it will gradually commence sales of the NPM G Series, a series of systems that can immediately respond to customer supply and demand changes through continuous, autonomous updates, and in turn make autonomous factories a reality.

Currently, when fluctuations caused by a range of factors lead to problems on the frontlines of production, companies rely on the expertise of specialists to find solutions. As these problems are caused by a range of irregular variables, the company believes that AI-based autonomous control and updates of the 5Ms-Man, Machine, Material, Method, and Measurement-all of which impact quality during production, can make autonomous factories a reality.

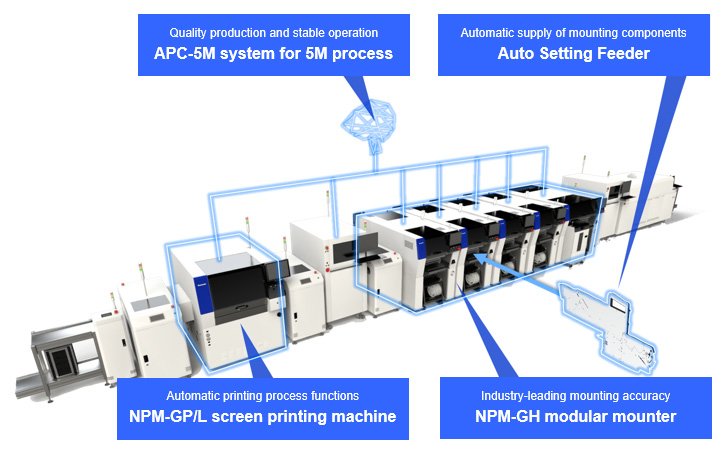

To begin with, on February 16, 2022, Panasonic released the APC-5M assembly line system, which identifies variation and applies changes in the 5Ms to stabilize production. The company will follow this with the release of the NPM-GP/L screen printing machine, which can automatically implement production line changes; the Auto Setting Feeder, an automated component supply system; and the NPM-GH modular mounter, which boasts industry-leading mounting accuracy. Through a new platform that brings together these technologies, the company will enable autonomous control of 5M production process variables, resulting in stable production. By adding the company’s intelligence in this area, it will aim to make autonomous factories a reality.

As a partner for co-creation, Panasonic will maintain close relationships with its customers, work with them to solve frontline issues, and strive to maximize their corporate value.

Customer inquiries: Customer Consultation Desk, Panasonic Smart Factory Solutions Co., Ltd.

https://industrial.panasonic.com/cuif/jp/contact-us?field_contact_group=1096

The recent changes in lifestyles and consumption habits are having huge impacts on supply chains. In the manufacturing domain of Gemba Process Innovation, which seeks to solve customers’ Gemba issues, the creation of assembly lines that can cater to sudden changes is presenting a major challenge. Panasonic believes it can provide a solution to this problem through factory automation. To automate factories, the company is working to reduce total cost of ownership through thorough 5M management and improve overall equipment effectiveness with 5M process control. Ultimately, the company aims to build autonomous factories that can immediately respond to customer supply and demand changes through continuous, autonomous updates.

Panasonic will utilize its strengths in edge devices, sensing, and robotics to collect key Gemba data and apply its unique technologies to optimize supply chains. In addition to initiatives to eliminate waste and standstills at each Gemba and automate Gemba improvements, the company will use Blue Yonder software to visualize and optimize supply chain links and ensure a continuous cycle of major improvements. In combining these two, Panasonic will aim to provide solutions that facilitate continued, autonomous improvements across the supply chain. The company has defined this concept as the Autonomous Supply Chain™. Accelerating efforts to achieve this Autonomous Supply Chain™ will enable the company to thoroughly reduce Gemba losses and standstills, contribute to customers’ management reforms, promote the effective use of resources, reform Gemba workstyles, and offer solutions to a range of other social challenges as well.

NPM G Series for Autonomous Factories

Using a smaller, lighter mounting head, NPM-GH achieves high-level productivity (max. 41,000 chips per hour-total number of assembled chips per hour under optimal conditions) with outstanding accuracy (±15 μm). The mounter can also be configured as the industry’s first ultra-precise specification (±10 μm). Additionally, an enlarged operation screen has improved the user interface, and with the ability to simultaneously control each side of the machine’s operability has also greatly improved.

With a printing accuracy of ±3.8 μm and a cycle time of 12 seconds, the NPM-GP/L boasts the world’s top solder paste printing performance. The company also offers an optional function for a fully automatic printing process. In addition to a “mask changer” that can stock up to ten different types of solder masks, the machine can automatically supply and collect solder, automatically reconfigure pin support of the substrate, and automatically undertake a range of other processes required for production line changes.

The Auto Setting Feeder is the industry’s first*2 feed mechanism that can automatically peel back the cover on surface-mount component tape between 4 mm and 104 mm wide. This has enabled the automatic supply of mounting components without the help of skilled workers. Further, when a reel of tape is finished, a loading unit automatically and instantly supplies the next reel. This eliminates the need for human intervention in the component supply process to facilitate full autonomy. Moreover, the use of a dedicated cart means that the current NPM and NPM-X series can support the Auto Setting Feeder without restructuring the entire line.

APC-5M monitors irregularities in the 5Ms in real time and detects production line changes. It then analyzes the accumulated data, identifies the cause, and uses empirical data to autonomously find a solution. This adds further empirical data, and so the more the system is used the more it grows into a highly precise system in customers’ factories. Further, during its real-time monitoring of the 5Ms, the system can focus on unit condition and determine which units need to be corrected and when. It can then undertake maintenance in times with the least impact on operations, and work with the host system to provide predictive replacement instructions.

Panasonic Corporation is a global leader developing innovative technologies and solutions for wide-ranging applications in the consumer electronics, housing, automotive, and B2B sectors. The company, which celebrated its 100th anniversary in 2018, operates 522 subsidiaries and 69 associated companies worldwide and reported consolidated net sales of 6,698.8 billion yen for the year ended March 31, 2021. Committed to pursuing new value through collaborative innovation, the company uses its technologies to create a better life and a better world for customers. Learn more about Panasonic: https://www.panasonic.com/global.

The content in this website is accurate at the time of publication but may be subject to change without notice.

Please note therefore that these documents may not always contain the most up-to-date information.

Please note that German, Spanish and Chinese versions are machine translations, so the quality and accuracy may vary.