Feb 24, 2026

- Products & Solutions

- Press Releases

Mar 02, 2021

Products & Solutions / Press Releases

- Unique temperature-resistant polymer technology reinforces solder connections between semiconductor packages and circuit boards

- Reduced solder cracking improves the reliability of electronic assemblies in harsh environments like automotive applications

- Expands portfolio of Surface Mount Assembly Reinforcement and Underfill materials

Osaka, Japan – Panasonic Corporation announced today that it has commercialized a temperature-resistant sidefill for surface mount assembly applications. Sidefill CV5797U improves both the reliability and productivity of automotive electronic assemblies. The company will launch the product in March 2021.

Automotive electronics need to operate reliably under severe service conditions like shock, vibration, and environmental temperature extremes. As automotive sensing, control, and communications have become increasingly sophisticated and powerful, the electronic systems enabling them are becoming more complicated; semiconductor packages are getting larger, interconnects are getting smaller and system designers are packing more components on every square millimeter of circuit board real estate. As a result of the increased component density, semiconductor packages are subject to greater thermal stresses over their operational lifetime which fatigues the interconnect joints, leading to solder cracking and ultimately to device failure.

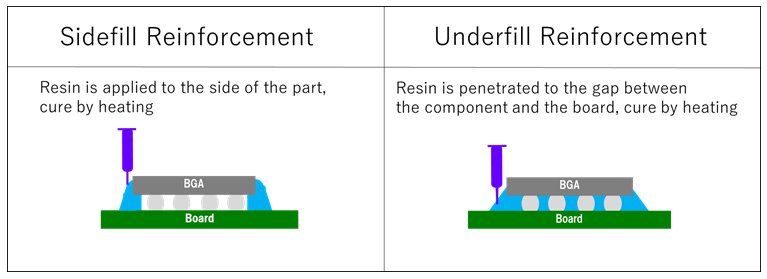

To address this problem, Panasonic is developing a portfolio of surface mount reinforcement materials including temperature-resistant sidefill, CV5797U. These products are based on Panasonic’s polymer formulation capabilities and flow control technologies. The new CV5797U sidefill is designed to prevent solder cracking by reinforcing the periphery of large semiconductor packages. Under ambient conditions, CV5797U has a pot life[1] of 72 hours, which is three times as long as conventional sidefill. A longer pot life reduces material handling challenges, contributing to higher productivity in the electronic assembly process.

This material can reinforce BGAs[4] larger than 25 mm × 25 mm

Reinforcing surface-mounted semiconductor packages and electronic components used in automotive camera modules, automotive communication modules (millimeter-wave radar modules), automotive ECUs (electronic control units), next-generation cockpits, headlights, and more.

The product will be displayed in SEMICON China 2021, which is scheduled to be held at the Shanghai New International Expo Centre from March 17 to 19, 2021.

As more electronic functionality is designed into automobiles, there is an increasing demand for the electronic assemblies to perform reliably under a wide range of operating conditions such as mechanical shock, vibration and temperature extremes both inside and outside a vehicle. One proven and effective method for improving assembly-level reliability is to reinforce the mounted components with a polymeric compound that is both highly resistant to heat and cold and exhibits minimal expansion and contraction due to temperature changes. Panasonic's CV5797U highly temperature-resistant sidefill for surface mount reinforcement is a product of the company's core polymer design expertise. This material strikes the right balance between a high glass transition temperature (Tg) and a low coefficient of thermal expansion (CTE) needed for automotive-grade applications. Component reinforcement with CV5797U mitigates the CTE mismatch between an automotive motherboard and a mounted semiconductor package, thus enabling a reduction in the stress exerted on the solder joints. During temperature cycling tests performed at Panasonic’s laboratory, no solder joint separation, cracks or failures were observed after 6,000 temperature cycles -55C to 125C, demonstrating the improved reliability of assemblies reinforced with CV5797U sidefill.

Panasonic's expertise in curing control technology resulted in a product with a pot life of 72 hours under ambient conditions. This is about three times longer than that of a conventional sidefill (CV5314). Due to the long pot life, the sidefill is easier to manage on the manufacturing floor, contributing to higher productivity in the mounting process. In addition, this sidefill technology drastically reduces reinforcement process time by approximately 90% when compared to a conventional underfill process and contributes to a reduction in the total assembly process cycle time. Additionally, this sidefill may be applied at high speed using a jet dispenser.

Panasonic's CV5797U highly temperature-resistant sidefill for surface mount component reinforcement has been developed utilizing flow control technology based on the company's polymer formulation expertise. When applied to the periphery of a package, the sidefill creates a reinforcing fillet around QFNs[5] as well as BGAs larger than 25 mm × 25 mm which is extremely difficult to achieve with underfill. CV5797U sidefill is indispensable for manufacturing automotive-grade electronic assemblies.

Panasonic Corporation Brand Strategy Division Corporate PR Department

https://news.panasonic.com/global/contacts/

Electronic Materials Business Division, Industrial Solutions Company

https://industrial.panasonic.com/cuif/ww/contact-us?field_contact_group=2343&field_contact_lineup=3241&ad=press20210302ww

Panasonic Corporation is a worldwide leader in the development of diverse electronics technologies and solutions for customers in the consumer electronics, housing, automotive, and B2B businesses. The company, which celebrated its 100th anniversary in 2018, has expanded globally and now operates 528 subsidiaries and 72 associated companies worldwide, recording consolidated net sales of 7.49 trillion yen for the year ended March 31, 2020. Committed to pursuing new value through innovation across divisional lines, the company uses its technologies to create a better life and a better world for its customers. To learn more about Panasonic: https://www.panasonic.com/global.

The content in this website is accurate at the time of publication but may be subject to change without notice.

Please note therefore that these documents may not always contain the most up-to-date information.

Please note that German, Spanish and Chinese versions are machine translations, so the quality and accuracy may vary.