Takeda has worked at the Utsunomiya Factory for 12 years. Though manufacturing of OLED TV briefly re-energized factory operations, the business continued to shrink over the long term, and the factory was unable to reverse the downward trend.

Takeda: “The decline in production made for a heavy atmosphere at the factory. The reduction in scale limited investment, which meant we couldn’t tackle new challenges. People started losing their pride in manufacturing. When I took over as Factory manager, the biggest problem was the culture. People felt a sense of crisis, but they couldn’t take concrete action. As soon as I came on board, I spelled the situation out clearly. Without change, the factory would disappear, one hundred percent. Change was our friend, not our enemy, and we had to take action now rather than each team member worrying about whether or not they were up to meeting the challenge. Failure just means ‘try again.’ Once trial and error became the whole objective, the culture started to transform.

“All the ideas for change, like restructuring the refurbishing process or creating relaxation spaces for employees, came from the frontline. Everyone started taking individual initiative and driving change without fearing it. That was a genuine sign that the factory was undergoing transformation.”

Panasonic’s refurbishing business has drawn internal and external attention, and employees have recovered their pride in manufacturing. A sense of vitality has returned throughout the factory, and positive cycles are being established, with everyone taking individual initiative to drive frontline reform.

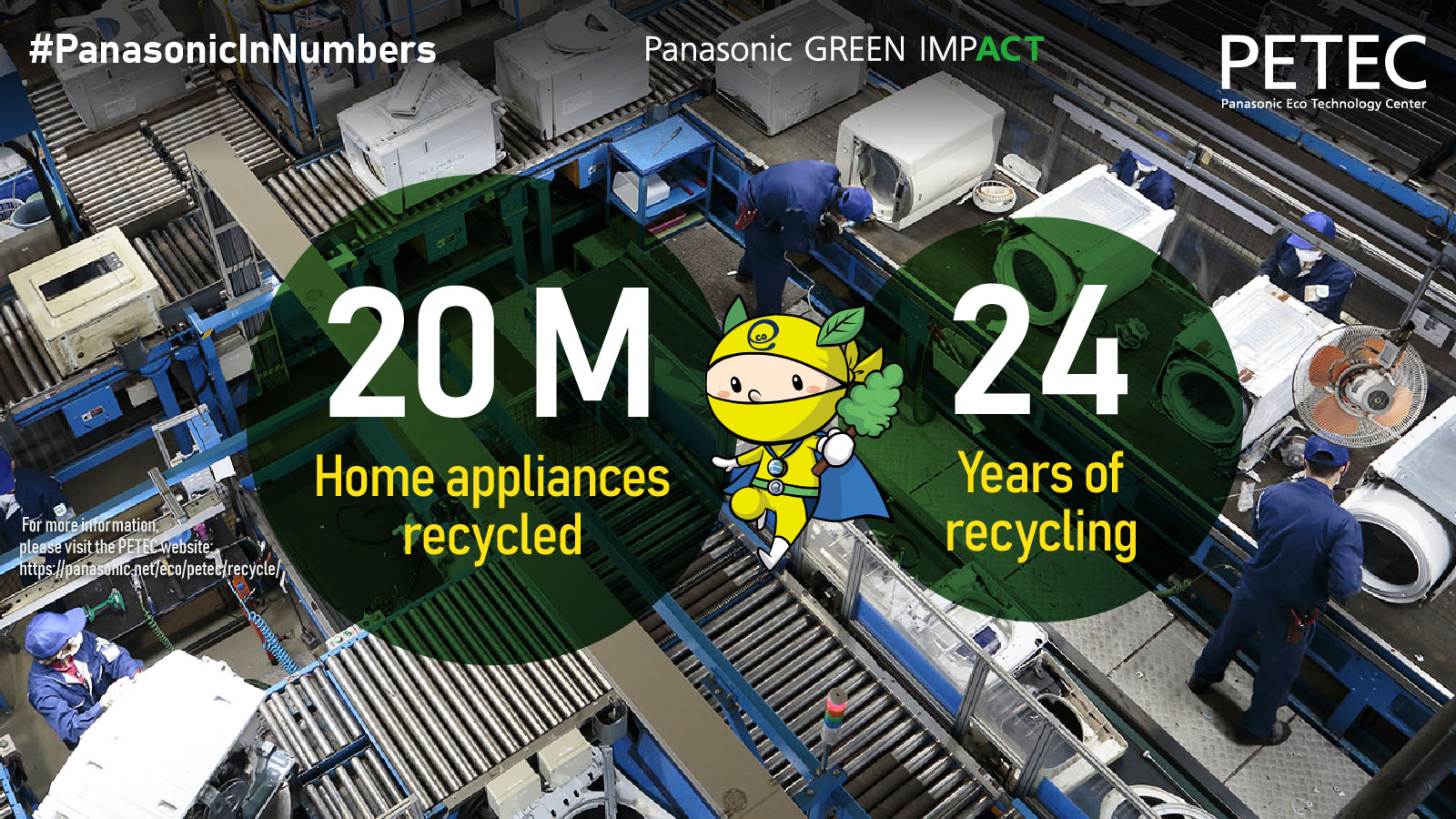

Takeda: “Reducing CO₂ emissions is a pressing global challenge. Consecutive days of extreme summer heat are concrete harbingers of major change in the global environment. We feel the weight of our responsibility to build a future where children can grow up with peace of mind. In this context, Panasonic’s decision to launch its refurbishing business represents a concrete step toward that goal.”

Takeda has put the refurbishing business on the right track. And he’s already raising his sights from Japan to the world.

Takeda: “The Utsunomiya Factory functions only as a hub for our domestic refurbishing business. For example, bringing used appliances back from Asia for refurbishing and resale makes no economic sense when you consider logistics costs and lack of familiarity with use conditions abroad. As such, the future vision of Panasonic’s refurbishing business is to establish a business model servicing individual countries or regions where products circulate. Conforming our approach to individual regions is the key to global business scalability.

“Our scale is still small, and we can’t claim to have acquired a solid competitive advantage yet. But by raising awareness of our refurbishing business, reinforcing our brand image as offering reliable products with long service lives, and providing not just new products, but refurbished products, I’m confident we can establish a solid competitive advantage. To this end, we have opened our refurbishing process to the public.* People’s surprise and approving reactions when they see how we’re bringing products back to life, and the way we’re practicing environmentally conscious manufacturing, is creating new Panasonic fans and ultimately strengthening our competitiveness.”

*Tours for the general public are offered weekly from Tuesday through Thursday. For tour information, click here (reservations required). Tours and tour bookings are currently available in Japanese only.