Dec 15, 2025

- Company

- Press Releases

Nov 09, 2022

Company / Press Releases

New recycling method using laser beam

Product dismantling technology for a recycling-oriented society

Osaka, Japan - Panasonic Holdings Corporation (PHD) today announced that the Manufacturing Innovation Division of PHD has developed a method for stripping the glass panels from the doors of glass-door refrigerators using a laser beam in the recycling process as part of its efforts to achieve a circular economy.

In its business activities, the Panasonic Group is striving to reduce CO2 emissions through its long-term environmental vision, Panasonic GREEN IMPACT (PGI), which aims to achieve both a better life and a sustainable global environment. As part of its PGI initiatives, Panasonic is actively promoting circular economy activities, including the development of this laser stripping method.

In light of the resource issues affecting the international community in recent years, the United Nations has set responsible consumption and production as a development goal (SDG Goal 12), calling for a significant reduction in waste generation and the efficient use of limited resources on a global scale.

Since 2008, the Panasonic Group and other consumer electronics manufacturers have launched refrigerators models with glass doors. Because the glass panels are difficult to separate from other materials, most of them are currently crushed and disposed of as industrial waste without being recycled.

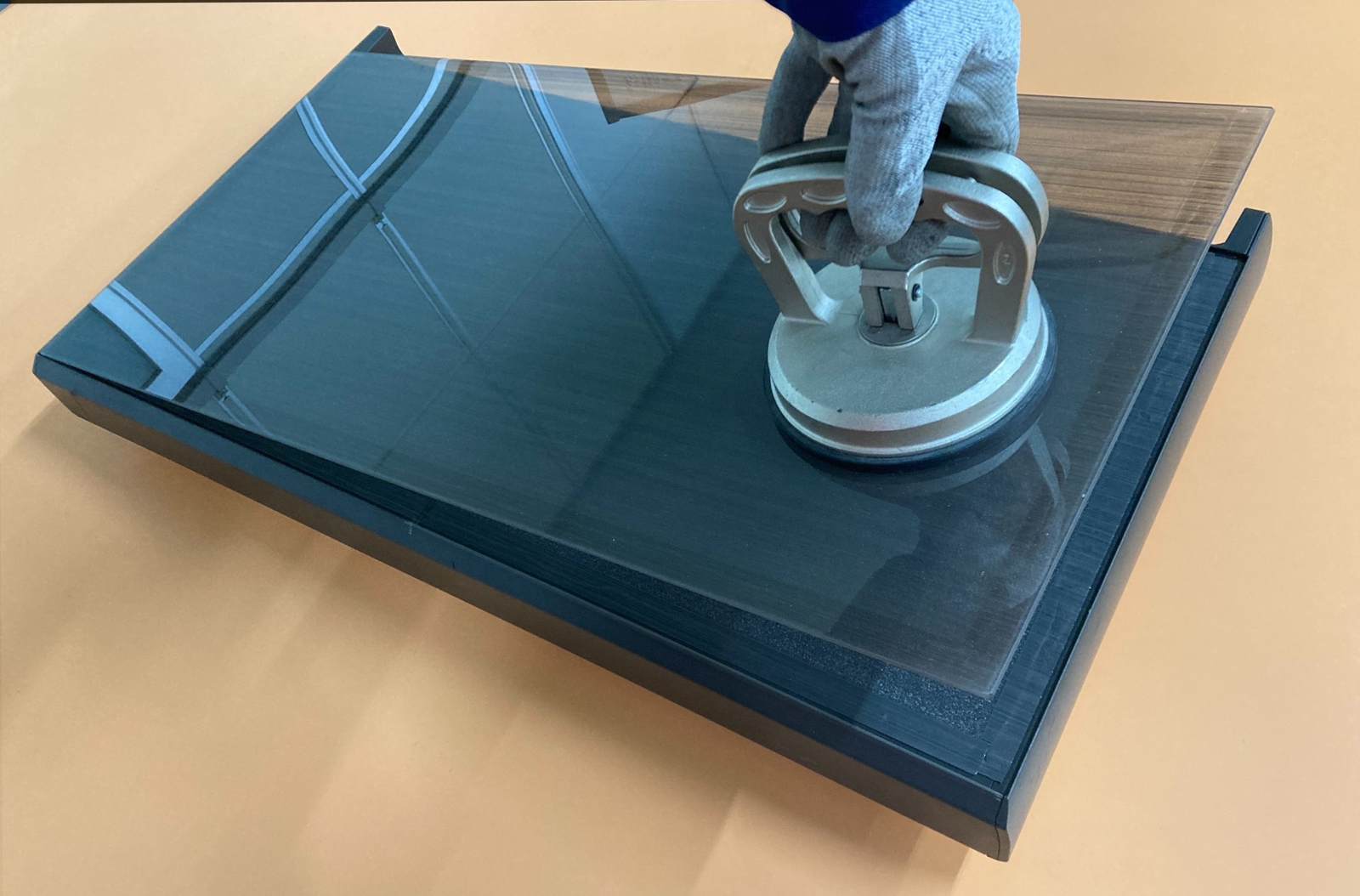

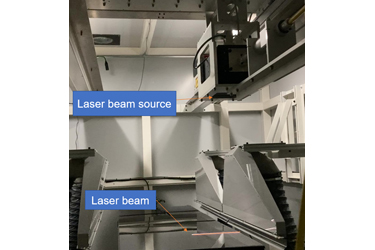

As many glass-door refrigerators are expected to be replaced by new ones in the coming years, their disposal is likely to become a major social issue. In order to solve this problem, PHD started the development of a method to enable glass recycling by separating glass panels from glass-door refrigerators in 2019. As a result, PHD has succeeded in developing a laser stripping method that allows only the glass panels to be removed from glass-door refrigerators by carbonizing the organic paint on the back of the glass using a laser beam that penetrates the glass on the door. This method is characterized by its ability to selectively peel off only the glass panel without removing the door from the refrigerator, allowing the glass to be separated as a single material in a simplified process. Since the glass removed from the door is in sheet form, and carbonized materials adhering to the surface can be easily removed, this method is expected to lead to an increase in the reuse of glass.

Following pilot testing, PHD will verify the effectiveness of the method for mass production at a recycling plant. As part of corporate activities for a sustainable society, PHD plans to expand this method to recycling plants both within and outside of the Panasonic Group in the future with the goal of achieving a recycling-oriented society.

Glass-door refrigerator

Laser irradiation

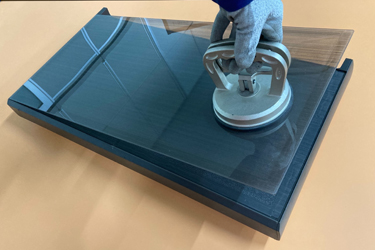

Removable with a suction pad

Removed glass panel and door

Removing glass from glass-door refrigerators, glass-top washing machines, smartphones, solar panels, and more

Promotion & Engineering Planning Department, Manufacturing Innovation Division

E-mail:midpress@ml.jp.panasonic.com

|

About the Panasonic Group Founded in 1918, and today a global leader in developing innovative technologies and solutions for wide-ranging applications in the consumer electronics, housing, automotive, industry, communications, and energy sectors worldwide, the Panasonic Group switched to an operating company system on April 1, 2022 with Panasonic Holdings Corporation serving as a holding company and eight companies positioned under its umbrella. The Group reported consolidated net sales of 8,378.9 billion yen for the year ended March 31, 2023. To learn more about the Panasonic Group, please visit: https://holdings.panasonic/global/ |

The content in this website is accurate at the time of publication but may be subject to change without notice.

Please note therefore that these documents may not always contain the most up-to-date information.

Please note that German, Spanish and Chinese versions are machine translations, so the quality and accuracy may vary.