Nuremberg, Germany - At Nürnberg Messe in Nuremberg, Germany, the SMT Hybrid Packaging (hereafter referred to as "SMT") exhibition and a tradeshow on power transistor devices and related technologies, the "PCIM Europe" (hereafter referred to as "PCIM") was held at the same time, from June 5 to 7, 2018.

More than 400 companies took part in each exhibition, and approximately 17,500 people working in the industry from across Europe visited. Panasonic Industry Europe (PIEU) also took part to showcase its latest products and solutions.

Here are some of the key products and solutions introduced.

SMT

At this exhibition, PIEU showcased an extensive line-up ranging from solder paste printers to mounters for chip parts, placement machines, and odd-form component insertion machine. PIEU also organized demonstrations to allow visitors to experience up close how these solutions worked. These machines work seamlessly together, and by implementing the iLNB co-developed with Siemens, Panasonic has given users total control over a system integrated with both Panasonic and non-Panasonic machinery. Furthermore, PIEU introduced its "Smart Factory" solution that enables remote management of the entire floor with control over multiple lines brought to life by integrating Panasonic's proprietary PanaCIM.

Moreover, PIEU implemented laser markers for the first time in Europe. Using a 5W carbon dioxide gas laser, this machine can etch QR codes, etc. on substrates. It can scan the circuits on the substrates using the scanner placed in front, etch the relevant code, and based on this code, the solution can automatically switch from machine to machine. This helps realize a more intelligent production line.

At SMT, PIEU also unveiled for the first time in Europe its modular mounter NPM-WX series, which improves production efficiency and quality, and demonstrated its capability to meet customers' varying needs regarding production capacity and its efforts to accelerate the realization of fully automated production lines.

PCIM

At this exhibition, state-of-the-art power transistor devices and energy-saving products that realize energy savings by enhancing energy efficiency for industrial equipment and automotive devices were introduced.

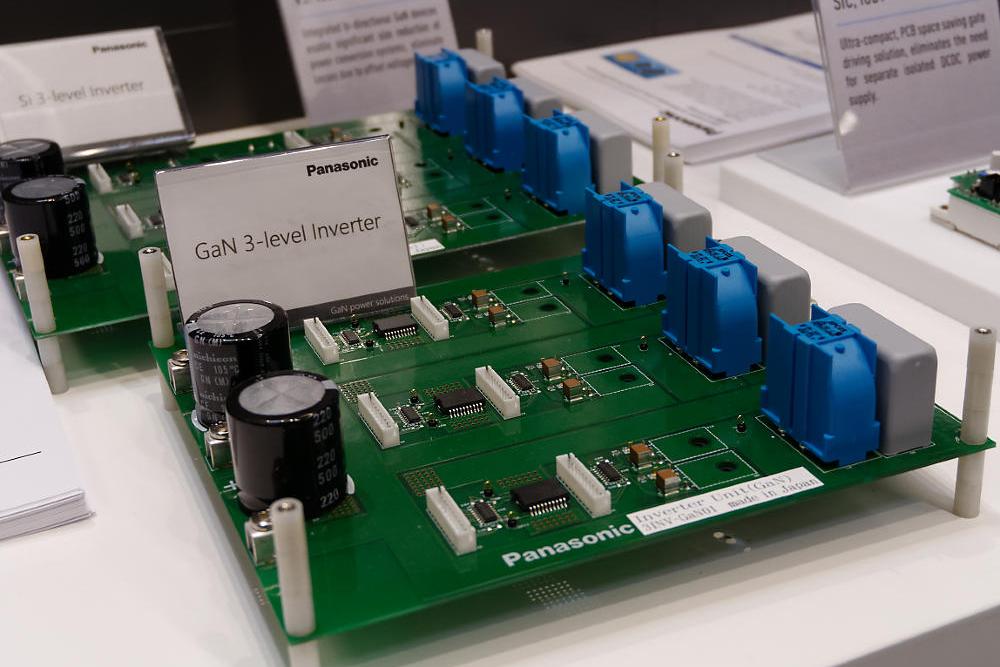

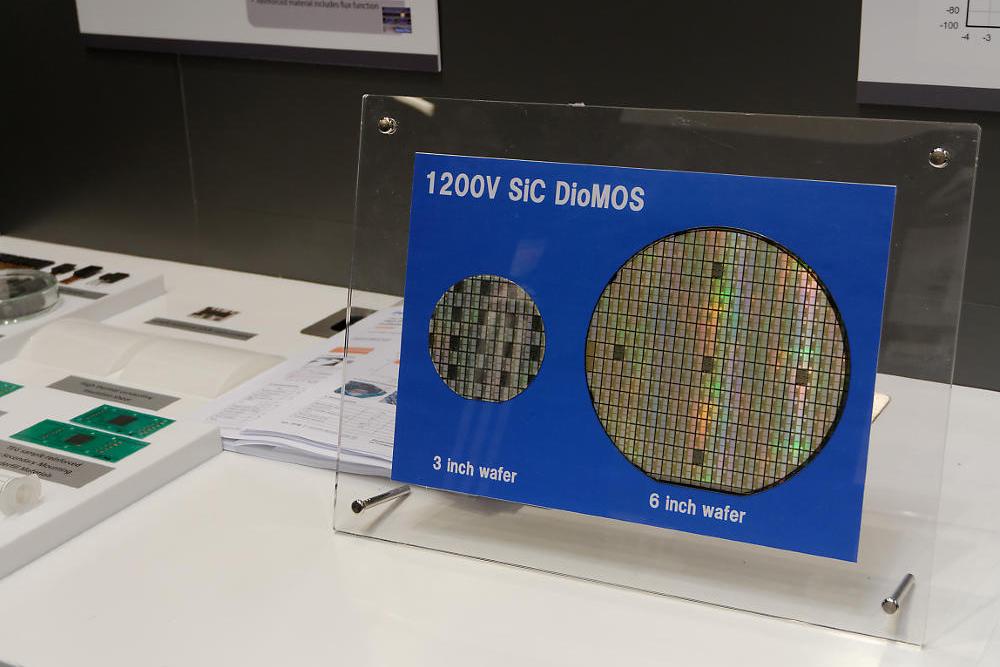

There is increasing interest in GaN (gallium nitride) and SiC (silicon carbide) high performance power transistor devices that can realize high energy efficiency that traditional Si (silicon) power transistor devices cannot.

X-GaN(TM) is a 600V GaN device developed by Panasonic that contributes to minimization and energy savings of devices. Recently, normally-off has become the standard for power transistors, but Panasonic was the first to realize this normally-off state. GaN has high frequency characteristics, and in comparison to other power transistors, it enables higher switching speed. Moreover, it boasts low conduction resistance, so it can suppress loss even at high currents. At this exhibition, PIEU showcased not only the X-GaN(TM) module, but also the motor driver embedded with the X-GaN(TM) in the motor of arm shaped robot. X-GaN(TM) also reduced internal heat emission, so the volume can be minimized to 1/4 the previous size, and the motor driver can be placed nearby the motor itself, thereby hopefully contributing to wiring reduction, which in turn will give way to high speed operation of arm robots, size reduction in the arm, and reduction in wiring costs.

With respect to SiC, PIEU showcased transistors equipped with reflux diode function necessary for power sources and inverters made possible by Panasonic's proprietary MOS-FET (DioMOS) structure. This has enabled the miniaturization of SiC-DioMOS, which PIEU also introduced at the exhibition. SiC power transistors have a higher energy efficiency than conventional Si power transistors so they are positioned as key devices for saving energy at high currents and high voltage, but SiC-DioMOS realizes both miniaturization as well as energy savings.

At this exhibition, in addition to power transistors, PIEU also exhibited graphite sheets (soft PGS), flexible heat insulating sheet, NASBIS, as well as various high performance passive components.

# # #

- Disclaimer:

- We would like to note that Panasonic Newsroom is not a place to address personal Customer Service issues. Even though this is not the forum, Panasonic is always eager to resolve your concerns. Our local customer services contacts can be found at Global Support or you can see our list of Social Media Accounts to find the right channel for your queries and concerns.

Related Links

Related News

- Great Expectations for Space Application - the Next Generation Power Device, "X-GaN" (Mar 22, 2018)

- Panasonic's Smart Factory Solutions Realize Higher Productivity Using Network Technologies (Sep 07, 2017)

- Panasonic Displayed Advanced Technologies Driving Power Innovation at PCIM 2017 in Germany - Power Electronics Focus (Jun 12, 2017)

- Panasonic Showcases Its Cutting-edge Smart Factory Solutions in Germany - Aspires to Introduce Industry 4.0 (Jun 07, 2017)

Photos

Panasonic booth at SMT Hybrid Packaging

![[Video] Panasonic Stories in 60 Sec: Panasonic HX](http://news.panasonic.com/uploads/tmg_block_page/cover_image/18401/60sec-panasonic-hx.jpg)

![[Video] Panasonic Stories in 60 Sec: Robot Control Platform Robo Sync](http://news.panasonic.com/uploads/tmg_block_page/cover_image/18349/60sec-robo-sync.jpg)