Tokyo, Japan - Panasonic Corporation is taking part in the International Robot Exhibition 2017 (organized by the Japan Robot Association and The Nikkan Kogyo Shimbun, Ltd.), which is being held at the Tokyo Big Sight from November 29 to December 2, 2017. The International Robot Exhibition is organized once every 2 years, and this year is the 22nd time it is being held. It is one of the largest exhibitions on robots that countless robot manufacturers and affiliated companies from Japan and across the world take part in.

In its booth, Panasonic is introducing people-centric robotics technology, safety evaluation research, devices, robots, and solutions that address a wide range of industries including manufacturing as well as the primary sector like farming and the tertiary (service) industry.

Autonomous Mobile Robot "HOSPI"

An autonomous mobile robot that provides solutions that require mobility such as delivery, surveillance, and showing people around. All you need to do is set the route and destination on the map, and the robot will be able to safely navigate even in areas with passersby. By also working with elevators and automatic doors and using infrared ID tags, the robot can operate in even bigger environments.

Panasonic has delivered over 40 robots to 15 facilities including hotels, lounges, and showrooms in Japan and other parts of the world.

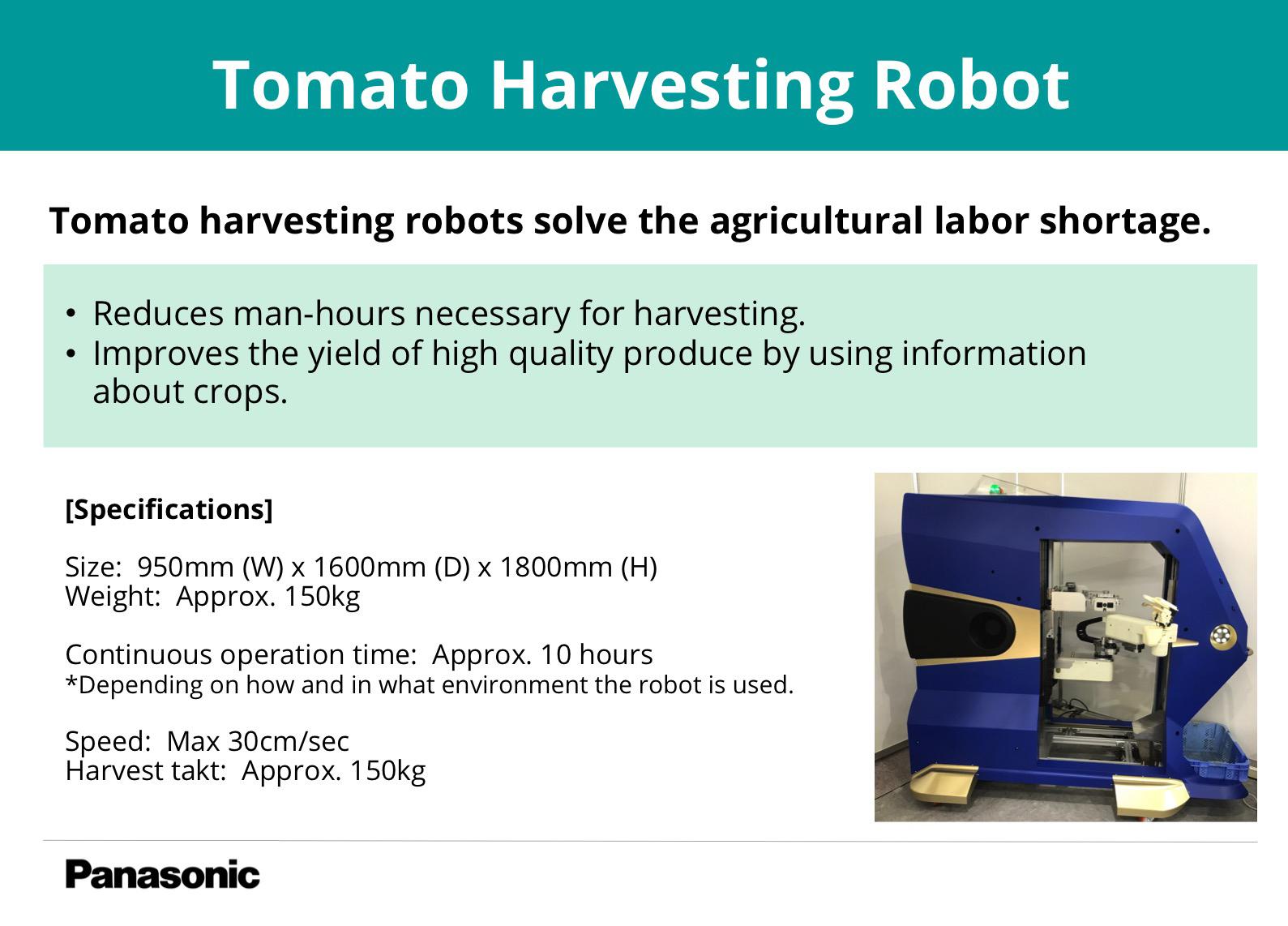

Tomato Harvesting Robot (currently under development)

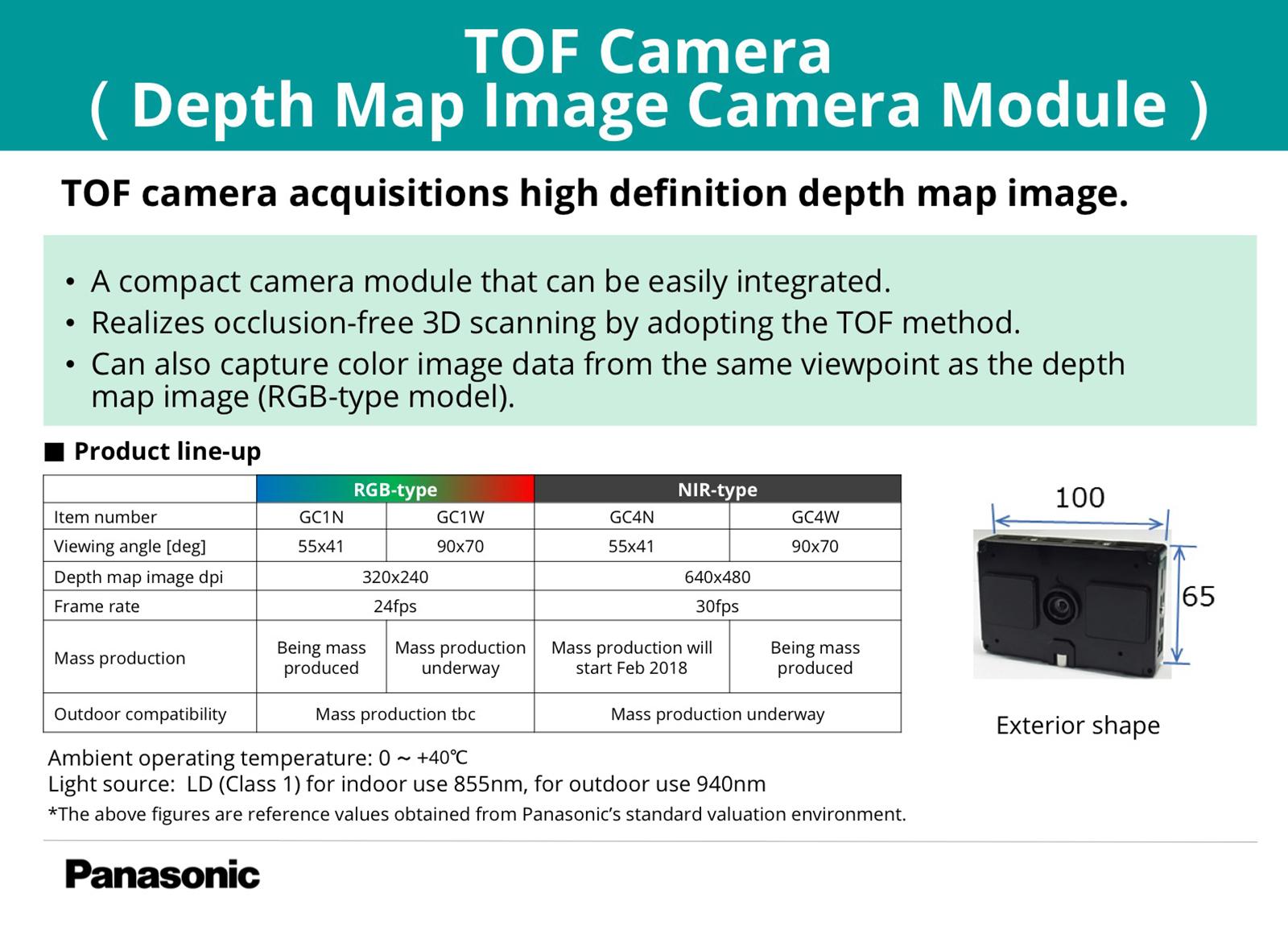

This robot can replace workers and help alleviate labor shortages in the farming industry. Not only will it reduce the man-hour necessary for harvesting, by using information about crops, it can help improve the yield of high quality produce. The robot takes high resolution range image from the TOF camera (time-of-flight) to accurately detect color, shape, and location. Then it pulls the fruit away from the stalk and carefully snips off the fruit at the abscission layer without harming it. It can also communicate and work together with basket carriers to create a smart farming system that can sort, harvest, and even store crops.

*This product is being developed with the assistance of National Agriculture and Food Research Organization Bio-oriented Technology Research Advancement Institution 's "Innovative technology development, emergency deployment project (using artificial intelligence to shape the future of farming)."

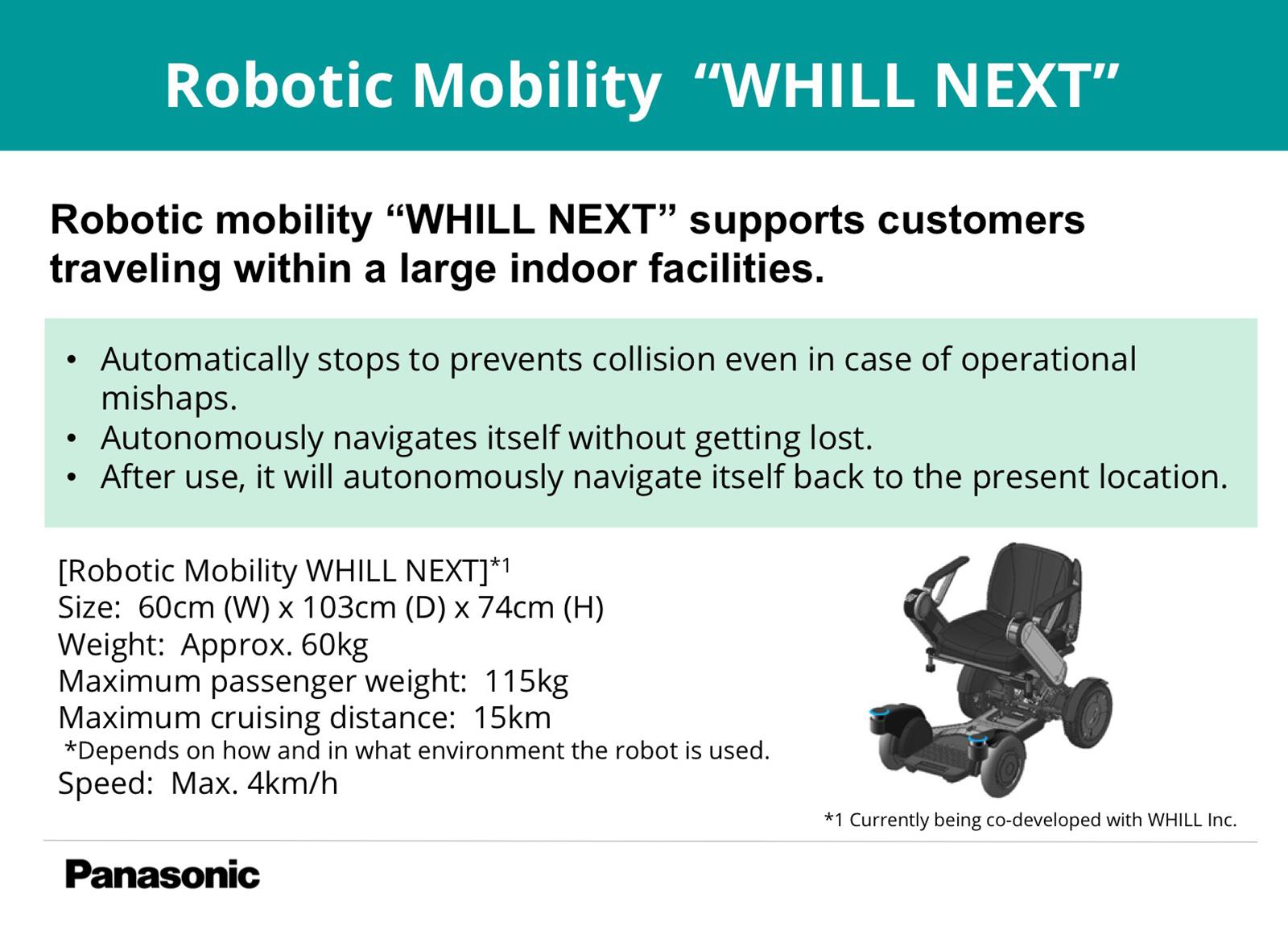

Robotic Mobility "WHILL NEXT" (currently under development)

An autonomous wheelchair that supports mobility in large indoor environments. When called, it will navigate itself to the user and then to the desired destination. This wheelchair will also automatically avoid any obstacles or people and automatically stop to prevent collision. After use, it will autonomously navigate itself back to the preset location.

*Being co-developed with WHILL Inc.

3D Light Detection and Ranging Sensor - 3D LiDAR (currently under development)

This 3D LiDAR serve as the "robots eye," and the laser is capable of scanning as wide as up to 60 degrees vertically and 270 degrees horizontally. In addition, the vertical scanning range and the resolution can be precisely tailored. Moreover, it can accurately detect objects under strong sunlight.

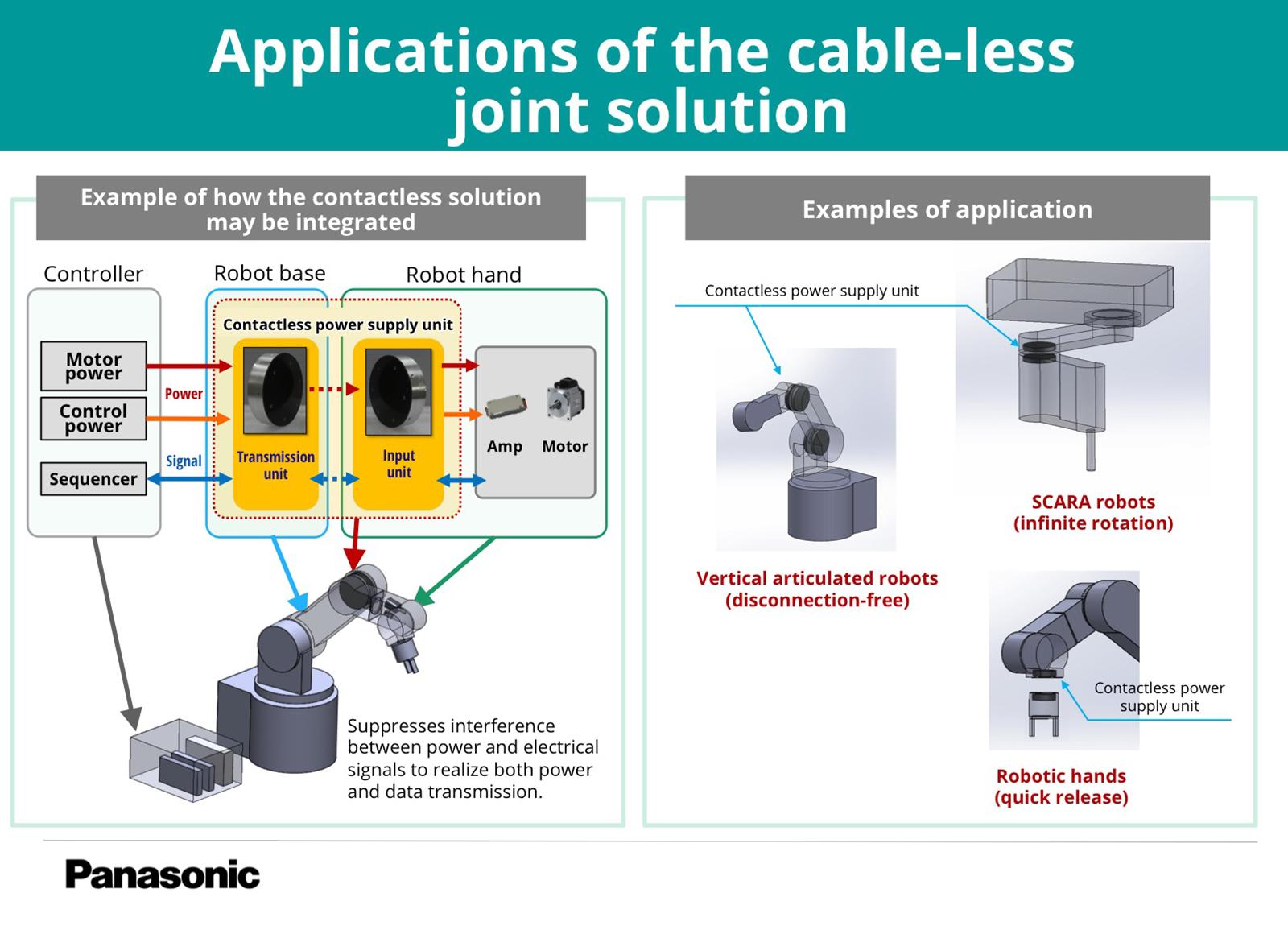

Wireless Power Transfer Unit for Robots (currently under development)

This wireless power transfer unit helps free robotic joints from cables. It can supply power to run the servomotor without cables. This will help alleviate disconnection caused by twisting cables, and thereby enable limitless movement and infinite rotation. By adopting a contactless power supply unit, Panasonic has brought to life a cable-less joint solution for vertical articulated robots, SCARA robots, robotic hands, etc.

Solution of Safety Design and Evaluation for Robots

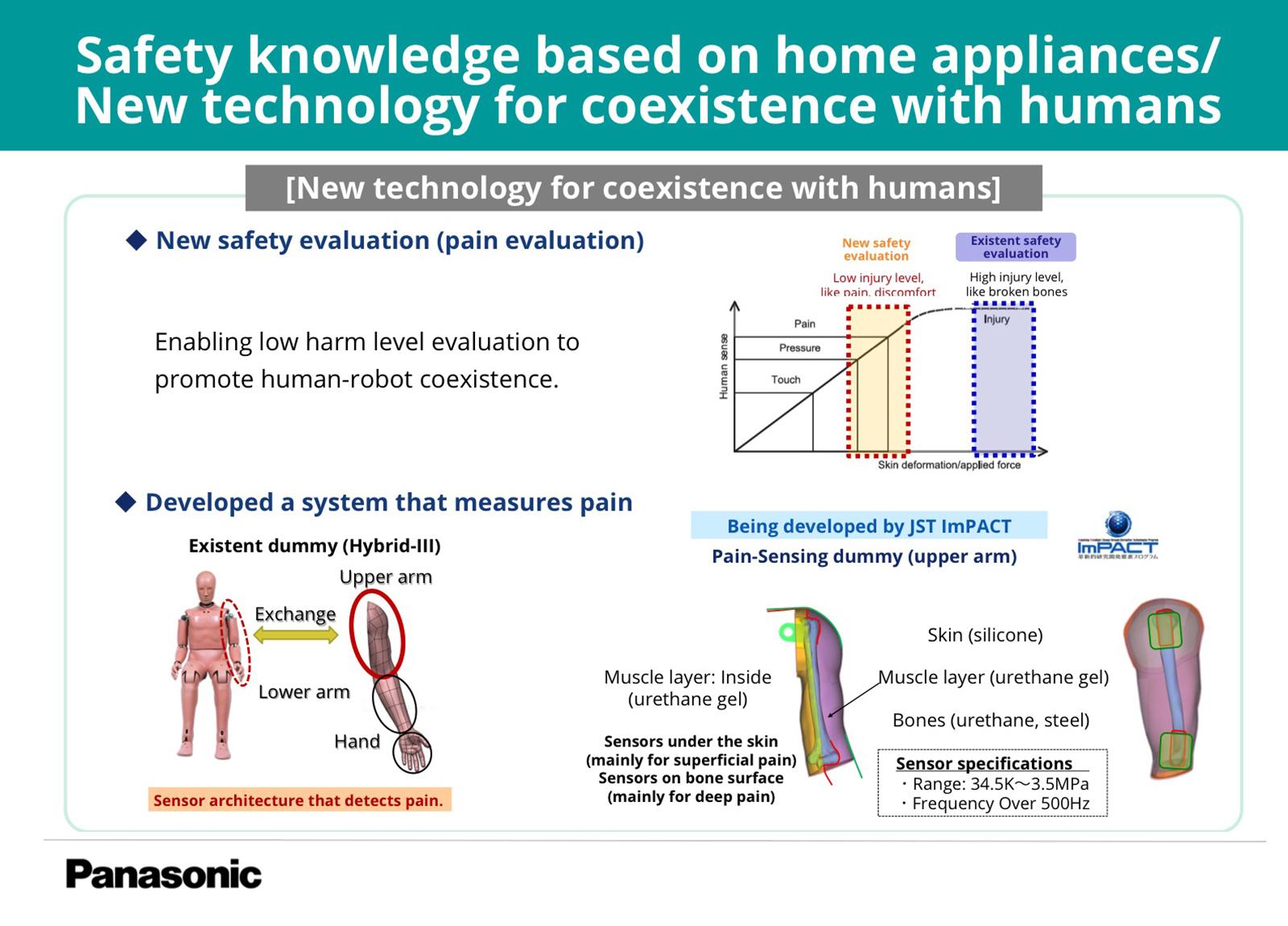

This service supports the evaluation and testing of robots at each process of the product lifecycle - "design," "prototyping," "mass production," and "market" to help develop safe robots. Panasonic will make available a wide range of evaluation testing like electrical tests drawing on the know-how about safety it has cultivated over the years making home appliances. Moreover, Panasonic has adopted new safety evaluation technology (pain evaluation) to help support the development of robots that are safe and can coexist with people.

Moreover, with respect to the effectiveness verification for robotic innovation, Panasonic is harnessing technologies and expertise on human studies such as ergonomics, emotional engineering, psychology, and physiology to scientifically examine the relationship between man and robot.

iREX - International Robot Exhibition 2017

Period: November 29 (Wed) to December 2 (Sat), 2017, 10:00 - 17:00 JST

Venue: Tokyo Big Sight East Hall [Access]

The Panasonic booth: Booth Number SR-79 in East 6 Hall

Admissions: 1,000yen (Pre-register from the organizers' page for free admission.)

Organizers: Japan Robot Association, The Nikkan Kogyo Shimbun, Ltd.

Official Homepage: English | Japanese

Power Assist Suit for the Forestry Industry

In the New Energy and Industrial Technology Development Organization, NEDO's booth, the power assist suit for the forestry industry, "TABITO-03," developed by ATOUN Inc., who is participating in the "Assist Suit Research and Development Consortium for the Forestry Industry" is being showcased for the first time. "TABITO-03" helps the user walk on slopes by detecting the posture of the user with pressure sensors placed on the bottom of the soles and angle sensors on joints, and by offering motorized support at the optimal timing. When climbing uphill, the power assist suit will help the user pull his/her leg up and step in, thereby helping to lift the user's body and making it easy to walk uphill. And when walking downhill, the suit will help put the brakes on the user's knee movement to reduce the burden on the user's knees. The suit comes with 4 battery-powered motors, 2 are located on the left and right side of the hip, and 1 each on the knees. The suit can stay operational for 3 hours. The newly developed "TABITO-03" will reduce the muscular load of people working in the forestry industry by up to 17%. This is the first time that data regarding the reduction in the muscular load has been documented.

The aforementioned consortium is comprised by Sumitomo Forestry Co., Ltd., Forest Research and Management Organization, ATOUN Inc., Nara Institute of Science and Technology. The suit is being developed with hopes of making it commercially viable by 2025.

- Disclaimer:

- We would like to note that Panasonic Newsroom is not a place to address personal Customer Service issues. Even though this is not the forum, Panasonic is always eager to resolve your concerns. Our local customer services contacts can be found at Global Support or you can see our list of Social Media Accounts to find the right channel for your queries and concerns.

Related Links

Related News

- Panasonic's Power Assist Suit Enters Joint Development of Construction Technology in Hong Kong (Nov 29, 2017)

- "Eyes" for Autonomous Mobile Robots - "3D LiDAR" Enables 3D Detection of Distances with Wide Angle of View (Oct 04, 2017)

- Power Assist Suit Demonstration Experiment at the 2017 Para Powerlifting Japan Cup - Helped Lighten the Load for Staff Handling Plates (Jul 28, 2017)

- Demonstration Experiments of the Autonomous Delivery Robot, "HOSPI(R)," Begin at an Airport and Hotel (Jan 12, 2017)

- Robot Technology in Harmony with People (Sep 20, 2016)

- [Press Release] Public Testing of Information Universal Design begins at Haneda Airport (Aug 8, 2017)

![[Video] Panasonic Stories in 60 Sec: Panasonic HX](http://news.panasonic.com/uploads/tmg_block_page/cover_image/18401/60sec-panasonic-hx.jpg)

![[Video] Panasonic Stories in 60 Sec: Robot Control Platform Robo Sync](http://news.panasonic.com/uploads/tmg_block_page/cover_image/18349/60sec-robo-sync.jpg)