Japan finds itself today painfully saddled with an aging population, a falling birthrate and a growing shortage of labor. So, the rush is on to use robotics to solve the unavoidable challenges facing the country. Amidst all that is going on, an initiative was launched to promote robot development via open co-creation. The "Robotics Hub" is the central axis of Panasonic's quest to integrate robots into society in the near future.

Summary of this article:

- Robots that perform the jobs that people do are increasing their presence in the primary, tertiary and other labor-intensive industries.

- Panasonic opened "Robotics Hub" as a center for developing "co-creative innovations in robotic applications."

- Through open collaboration, the Robotics Hub is set up, for starters, to liberally launch needs-driven robots that can help solve social challenges.

- Beyond that, their eyes are set on "Augmentation," or enhancing human abilities via robots, and a world where robots are more common to all.

Technological Progress is Driving the Market of Next-Generation Service Robots

Nine years ago, in 2010, the New Energy and Industrial Technology Development Organization (NEDO), one of the largest public research and development management organizations in Japan, released some very curious data. In their future market projections of domestic robot turnout, they forecasted a sharp expansion of robots in the services field by 2035. By "services field," it is meant medical care, logistics, nursing and welfare, cleaning, security and so forth.

And, there is data to back their projection. Though these statistics are on a global basis, according to a report by the International Federation of Robotics (IFR), sales of professional service robots in 2017 increased 39% to 6.6 billion US dollars. The strongest demand was for logistics systems, followed by medical robots and field robots, which mostly comprised milking robots, in that order.

Up until now, robots mostly served secondary industries, as so-called "industrial robots" for manufacturing plants accounted for a large share of the market. However, robots that perform the jobs that people do are increasing their presence in the primary, tertiary and other labor-intensive industries. What is urgently needed today are robots that make the jobs people do easier, so it is necessary to define "who does what, where, when and how."

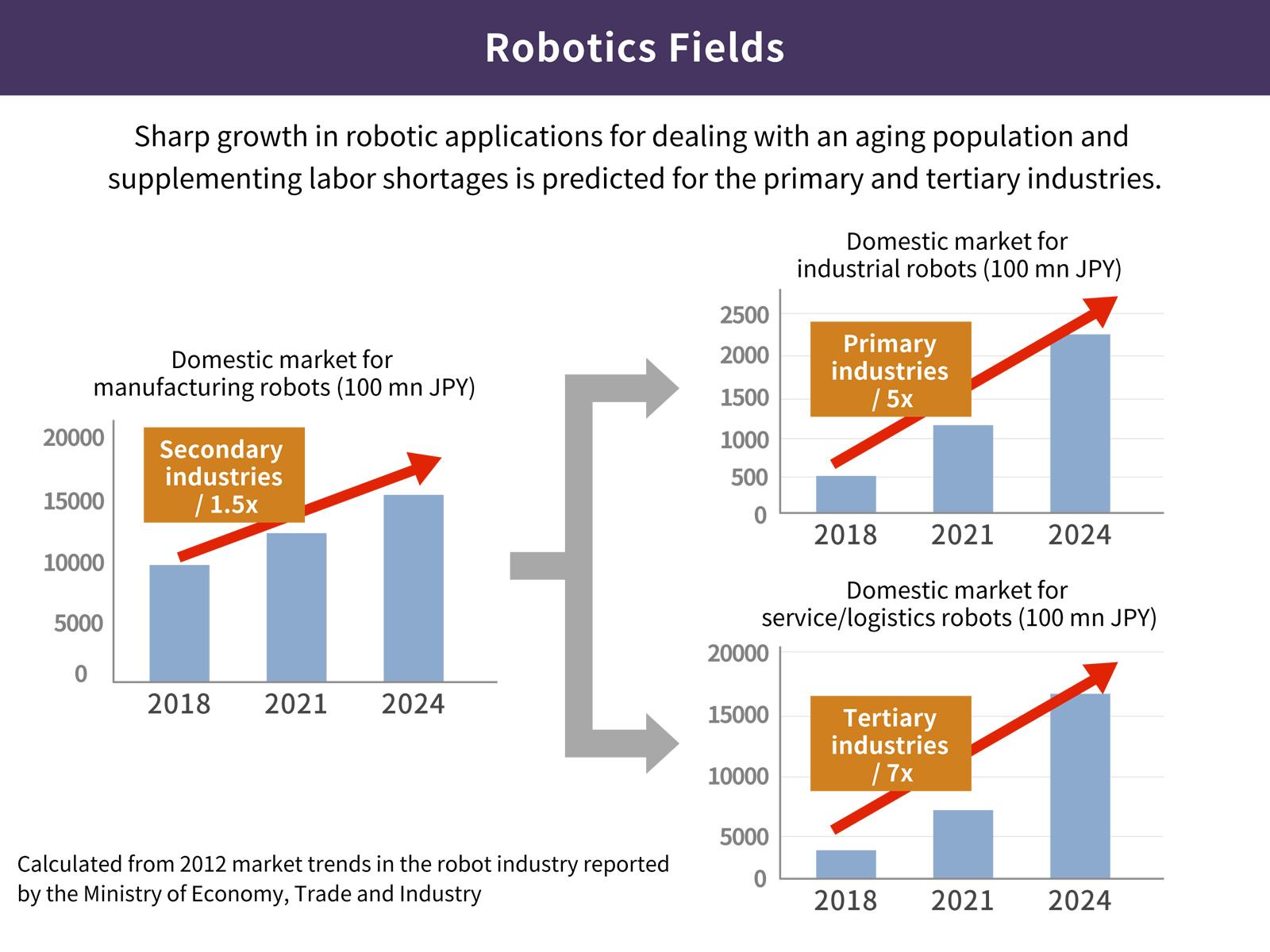

Robotic applications for dealing with an aging population and supplementing labor shortages are growing sharply and are predicted to continue that trend in the primary and tertiary industries.

As for service robots, because of the numerous points of contact with users, it is not only important that they move as commanded but that they also work in close proximity to people. Therefore, the top priority is naturally to ensure safety and security at all times, but, on top of that, service robots must be easy for those who rely on them to use and ultimately help improve productivity and efficiency. Looking ahead, robots will have to be increasingly more intelligent to work with people since people have a "mind." In that regards, though progress continues to be made with AI, IoT and control and other technologies that are closely tied to robotics, it is next-to-impossible for a single company to go it alone from start to finish.

Against this backdrop, Panasonic opened "Robotics Hub" as a center for developing "co-creative innovations in robotic applications," in Kadoma, Osaka in April 2018 and in Shiodome, Tokyo in December that same year. They are using these centers to accelerate cooperative projects with other businesses and academia.

Panasonic's "Robotics Hub" was established to speed up the co-creation of robotic innovations.

Equipping Society with a Good Balance of Automation and Human Augmentation

In response to the question of why Panasonic was investing time, money and resources into robotics, Mr. Takeshi Ando, who heads the Robotics Hub oversight board, gave the following answer.

"First of all, it's because, with Japan's birthrate declining and the population getting older, there's the issue of how to maintain the labor force going forward. Robotics are one very promising solution to that. Panasonic's mission is built on the concept that a 'company is a public entity of society,' so guided by that line of thinking, we are committed to serving the future needs of this world."

Takeshi Ando

Section Manager/Expert, Robotics Promotion Department, Manufacturing Innovation Division

Panasonic Corp.

"Another reason is that we are confident in our ability to provide the next generation in robotics. At Panasonic, manufacturing is in our blood and, over the years, we have promoted automation and production engineering at manufacturing plants of diverse variety. In the service robot field, we already have products like our autonomous delivery robot 'HOSPI®' and our rise assisting robot 'Resyone Plus.' With these applications to show for it, we see avenues for developing the technologies that we've constantly improved on and the know-how that we have amassed in the process for non-factory fields."

Hospital autonomous delivery robot "HOSPI®"

As mentioned earlier, Panasonic's Robotics Hub is a co-creation center. There, research and development is promoted as an open collaboration with both outside interests and within the company. For the most part, cooperation with outside interests is handled in Tokyo, while Osaka is in charge of cooperative projects within the company.

As Mr. Ando pointed out, "When people lie in the midst of a robot application, the robot becomes structurally very complicated because many more technologies have to be integrated than would be otherwise. Moreover, the speed of PDCA cycles is accelerating and it would be difficult for a company to catch up with it while trying to develop everything from 0 to 100 on its own. Collaborating with other companies is a must. That being the case, we felt a place where all of the participating parties could put their wisdom, technologies and strengths on the table would be critical, so we established the Robotics Hub."

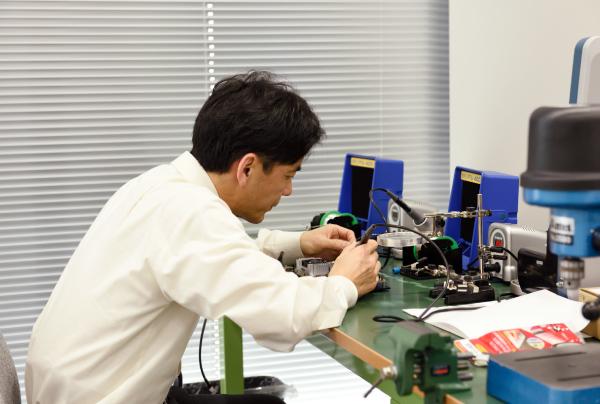

Joint research and development goes on every day at Panasonic's Robotics Hub.

One example of the collaboration going on at the Robotics Hub is the co-creative work that Panasonic is doing with WHILL Inc., a manufacturer of personal mobility solutions. Engineers from both companies are on-site and constantly bouncing ideas off each other to develop a next-generation product dubbed the "WHILL NEXT," which highlights one of the big merits of the Robotics Hub - a productive environment that allows ideas to be tested and honed immediately and repeatedly.

To get the facility up and running, Mr. Ando and his team spent a full year meticulously taking inventory of the company's robotic technologies and assets. All of that has been documented and is now being shared within the company. As Mr. Ando explained, "By sharing this information, we can see where our strengths lie and, inversely, where they are lacking. And, by preparing modules of supporting and elemental technologies, and using them to build platforms, we can speed up development and create new values. In fact, helping to efficiently match technologies and assets is part of the mission at the Robotics Hub."

"WHILL NEXT" self-driving wheelchair jointly being developed by Panasonic and WHILL

Since the December opening in Tokyo, tours of the Robotics Hub in Shiodome have been non-stop with some 400 visitors in just four months. That alone testifies to the widespread attention the centers are drawing. Numerous inquiries have come from within Panasonic, too, as not only engineers but also sales reps have joined the network. Mr. Ando was quick to emphasize, "Sales staff are picking up on what this customer and that customer want and feeding that information to the hub, so market needs are continuously and naturally reflected in activities. That kind of thinking is incredibly important." Mr. Ando was speaking from experience having seen in the past how robots developed solely with the ideas of engineers did not fit the intended application.

He added, "What is the right solution for each issue? Robots are one option, but you're putting the cart before the horse if your thinking is 'I've got this robot over here, so why don't you give it a try?' The idea used to be to have robots do everything, but, based on experience, our current approach is to have the customer control certain things and make sure that they get adequate use of the robot even at current performance levels."

For starters, the plan is to agilely develop and liberally launch robots loaded with automated features that society will find useful. The vision further down the road is "Augmentation" - enhancing human abilities via robots. Panasonic is doing joint research into separate aspects of human augmentation with six universities, amongst which are the University of Tokyo, Tohoku University and Waseda University. In April, they launched "Aug Lab" as an interdisciplinary virtual laboratory.

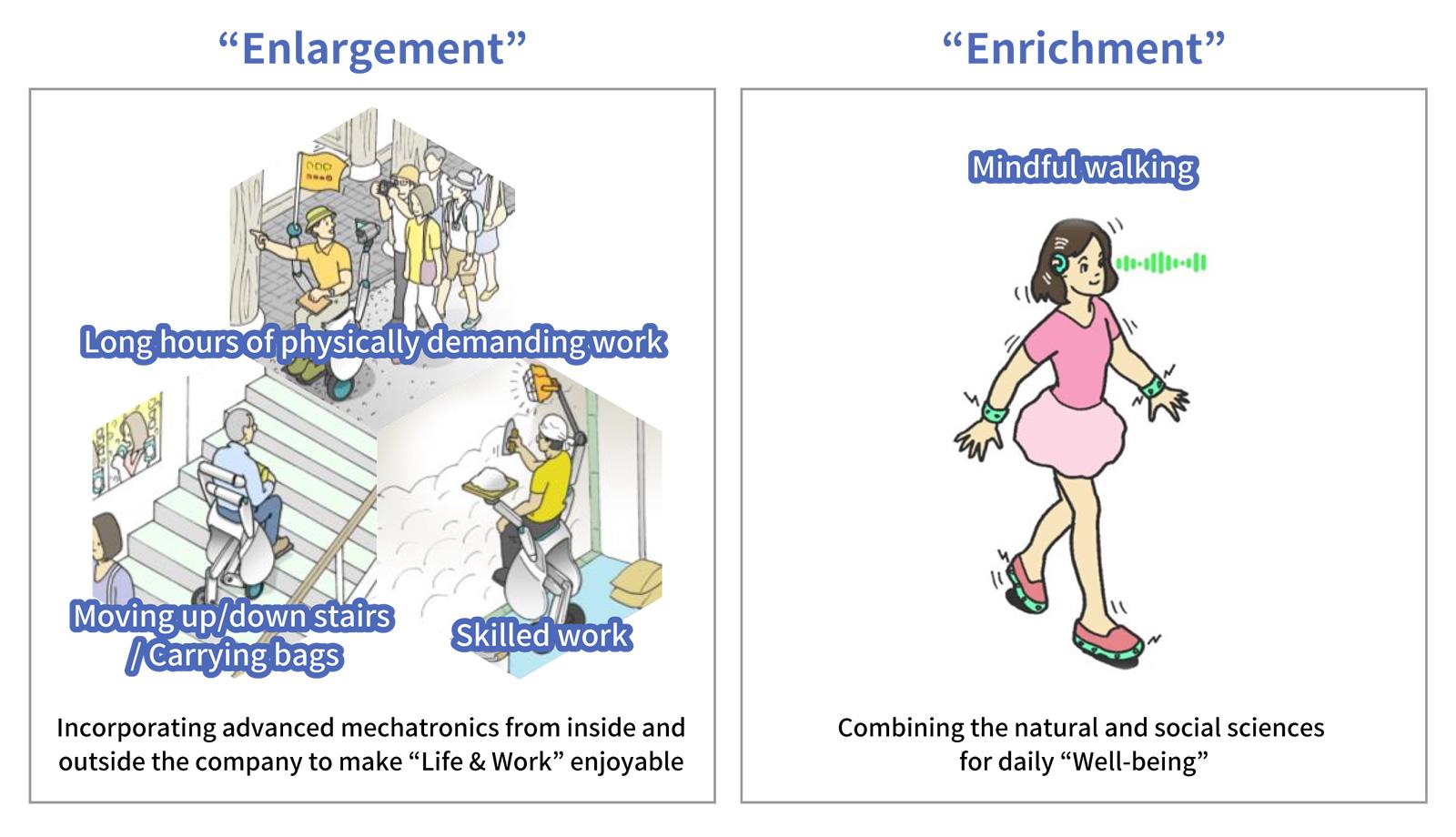

Two imaginable directions in human augmentation are quantitative augmentation referred to as "enlargement" and qualitative augmentation referred to as "enrichment." The "3rd Arm" introduced later is a perfect example of the user benefits of enlargement: by enabling one person to do the job of two, users might be able to work longer. The idea is to have a robot that motivates and assists the user by one's side.

"Enlargement" uses advanced mechatronics to enhance human abilities and work performance. "Enrichment" taps into the five senses by extending techniques (psychophysics, cognitive science, etc.) for monitoring and analyzing people.

Though hard to put into words, enrichment basically expands one's feelings. One demo that people can try has the user walk on an image of gravel typically found at shrines in Japan wearing vibrating devices that convey a sense of touch, which creates the sensation of walking on real gravel. Because it acts on sensorial processes, the content is considerably challenging.

Mr. Ando explained, "We're looking at human augmentation from the viewpoint of how it can improve quality of life. A proper balance of automation and human augmentation in the world could make life better. That's the future we're imagining." If these ambitious efforts are successful, there will come a time when robots coexist amongst humans.

What an Exciting Future a "3rd Arm" Would Bring

Waseda University and Panasonic are jointly researching a "3rd Arm" at the Robotics Hub. The project is headed by Hiroyasu Iwata, Professor of Modern Mechanical Engineering at Waseda University's School of Creative Science and Engineering and Director of the Global Robot Academia Laboratory.

Prof. Iwata has for some time been exploring the possibilities of physical augmentation using robotics. One idea he came up with was a third arm. Mounted on the user's shoulder, this robotic arm would perform sub-tasks when both of the user's arms are occupied.

Generally speaking, this research may not have the luster to picture robots looking like humans. But, twelve years ago, Prof. Iwata developed a very articulate patient care robot. As he explained, "It was an automatic robot that could lift, carry and care for people, but not having seen where it would be used, we didn't reflect user needs in it. Sophisticated humanoid robots are not worth the cost, but, more importantly, you don't need to go that far. Simply having a lot of functions makes a robot little more than a showpiece. The first thing you should do is to imagine who is going to use it and how. That experience convinced me that the way people think about manufacturing would eventually change." Because of that experience, Prof. Iwata turned the rudder towards the possibilities of physical augmentation with the objective of introducing practical applications in society.

Hiroyasu Iwata, Ph.D.

Director, Global Robot Academia Laboratory

Department of Modern Mechanical Engineering, Waseda University

In his cooperative work with Panasonic, the key is "needs-driven manufacturing." Looking back during a press conference at the Robotics Hub where announced and demonstrated the 3rd Arm by holding in place and screwing in a ceiling panel by a person, Prof. Iwata recounted, "What got me onboard was, during a talk with Panasonic, hearing about how hard installation work can be." He went on to describe the 3rd Arm as "your own personal concierge, so to speak. It allows you to do jobs by yourself that you couldn't do before. So, you can accomplish more on your own. And, when that happens, you change the way you go about things. That's where it gets interesting."

Currently, an eyeglass fitted with a sensor is the mechanism used to instruct the robotic arm. But, a lot of fine-tuning is needed going forward as Prof. Iwata pointed out, "It is very hard to get a robot to reproduce movements that people don't even think about." So they expressly want to make an articulated, physical augmentation robot by having Panasonic provide the control technology and elemental mechanical engineering and combining that with the insight from Waseda University. In research to come, they will be aiming at smarter, more intelligent operation by loading the robotic arm with audio and image recognition, AI and other technological goodies. Ideally, Prof. Iwata sees a "'human-machine integration' that doesn't feel strange when worn."

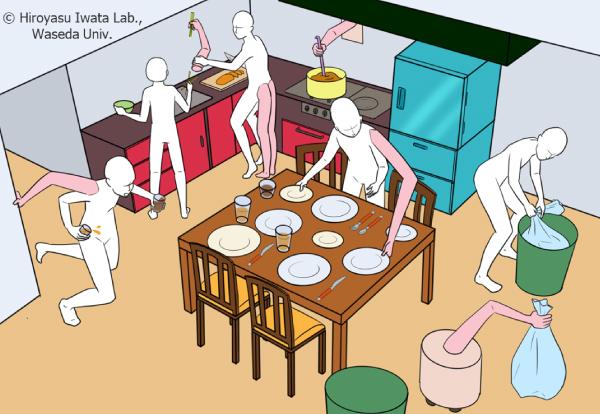

Prof. Iwata continued, "If you add a utility component, another direction you can take this is future lifestyles. At my research lab, I explain the 3rd Arm using an illustration that makes the merits of it easy to understand. It's not Doraemon, but everything begins with the thought that 'that would be nice to have.' Dreams are born from that and everyone can look at those dreams from the same angle. Then, if everyone moves in the same direction, you generate more power and teamwork. Panasonic and I want to do the same thing. We share the same vision. We want to make the future interesting."

Future living environment with the "3rd Arm"

By getting people on the outside involved, Panasonic's Robotics Hub having gotten off to a good start. There is plenty going on there that will get your hopes up for some eye-popping innovations in the not-so-distant future.

- Reproduced from the website "Mirai-kotohajime," by courtesy of Nikkei Business Publications, Inc.

# # #

- Disclaimer:

- We would like to note that Panasonic Newsroom is not a place to address personal Customer Service issues. Even though this is not the forum, Panasonic is always eager to resolve your concerns. Our local customer services contacts can be found at Global Support or you can see our list of Social Media Accounts to find the right channel for your queries and concerns.

Related Links

Related News

- ANA and Panasonic Partner to Test Self-Driving Electric Wheelchairs at Narita Airport (May 16, 2019)

- Panasonic Receives the Most Number of Awards at the Good Design Award 2018, with Three Products in the Good Design Best 100 (Oct 11, 2018)

- Panasonic Conducts Demonstration Experiment of Autonomous Signage Robot, "HOSPI(R)" at Narita Airport (Jan 18, 2018)

- Panasonic Autonomous Delivery Robots - HOSPI - Aid Hospital Operations at Changi General Hospital (Jul 23, 2015)

- Developed with Teamwork, Cleaning Robots Busily Vacuum the Floors During the Wee Hours at Tokyo Midtown Hibiya (Apr 22, 2019)