Mar 31, 2025

- Company

- Feature Story

- Panasonic GREEN IMPACT

- EXPO 2025

The first ballast water management system using in-line electrolysis in Japan is filter-less and designed to help save costs and space.

Panasonic Environmental Systems & Engineering Co., Ltd., a Panasonic group company, today announced that it has developed an on-board ballast water management system using an in-line electrolysis method to disinfect ballast water.

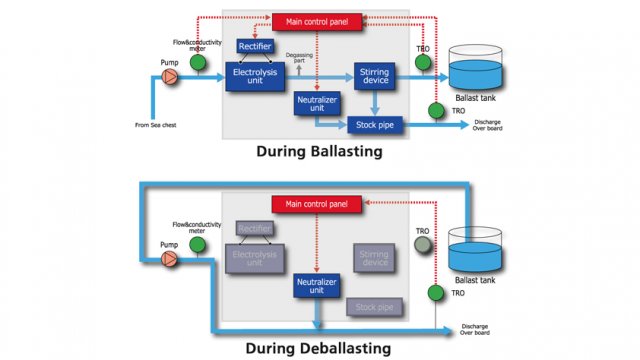

In the newly developed ballast water management system, called "ATPS-BLUE sys", an electrolysis unit is placed in the main ballast water pipe. The unit generates hypochlorous acid to disinfect the microorganisms in ballast water(*1) that may have been taken on board when taking in ballast water. The ATPS-BLUE sys also employs the company's original "stirring device" that enhances the efficacy of the sterilization, so that microorganisms in ballast water will be treated to fully conform to the discharge-standards by the International Maritime Organization (IMO) without using filters.

The ATPS-BLUE sys is a filter-less system, making backwashing and changing of the filter cloth unnecessary. As it is also scalable according to the volume of the ballast water to be treated as well as the ship's internal layout, the system helps utilize the limited space on board.

Ballast water, which is used to maintain balance and stability when the ship is empty of cargo, has been identified as a key factor responsible for bringing invasive species of microorganisms such as plankton and bacteria into non-indigenous environments, causing a major threat to marine ecosystems. All ships in international voyages are required to manage their ballast water and sediments in accordance with the International Convention for the Control and Management of Ships' Ballast Water and Sediments (BWM Convention) which the IMO adopted in February 2004. They are required to reduce the concentration of aquatic organisms in ballast water to below certain levels (D-2 Standard)(*2) before discharge in order to prevent trans-boundary movement of harmful aquatic organisms and pathogens that unmanaged ballast water discharge may cause.

For the ATPS-BLUE sys, Panasonic has submitted an application to the IMO for G9 Basic Approval (G9BA)(*3) in September 2013 and has started testing for G9 Final Approval (G9FA)(*3) and land-based test according to G8 Guidelines(*4). After obtaining G9FA and approval from the Ministry of Land, Infrastructure, Transport and Tourism, Panasonic is aiming to release the products of "ATPS-BLUE sys" for sale in the fiscal year starting in April 2015 through Exeno Yamamizu Corporation headquartered in Tokyo.

Panasonic's new ballast water management system will be on display at the exhibition of "SEA JAPAN 2014" to be held at Tokyo Big Sight (East Halls 1 and 2) from April 9 to 11, 2014. More details on the exhibition can be found at: http://www.seajapan.ne.jp/en/index.php

1. The first ballast water management system using in-line electrolysis in Japan to disinfect microorganisms in ballast water

In comparison to the in-line method, the off-line method, in which hypochlorous acid is generated outside and injected into the main ballast water pipe, requires pre-treatment filters to remove large organisms (50μm or larger), and it is necessary to clean or replace these filters. With the newly developed processing method, by setting an electrolysis device in the main pipe to generate hypochlorous acid and enhancing the sterilization effect with the company's original "stirring device", it has been possible to disinfect microrganisms in ballast water, including those in the size of 50μm or larger. The system's performance has fully satisfied the IMO's cleaning standards without filters.

2. Filter-less system without the need of backwashing or filter cloth replacement

As the system is filter-less, there are no troubles such as clogging or wear, so that it does not affect supplying ballast water. In addition, the ease of maintenance and absence of consumable items reduces running costs without increasing pressure loss for long time operation.

3. Flexible layout in accordance with ship's internal structure to save space

The compact-designed electrolysis unit having electrodes with the increased efficiency of generating hypochlorous acid, and the stirring device, which are the main components of the system, can be adjusted in size and shape to match with the treated volume of ballast water and the ship-space, efficiently utilizing the limited space available in the ship.

*1. Reduction of microorganisms in ballast water to levels under the D-2 standard of the BWM Convention.

*2. D-2 Ballast Water Performance Standard dictates the quality of discharge water from ballast water treatment systems as follows:

*3. Ballast water management systems need to be approved in accordance with IMO guidelines. The G9 guidelines cover "the procedure to approve a ballast water management system that uses an active substance" (D-3.2 regulation). G9 has a two-step approval process: basic and final approvals. Basic approval is granted on the basis of laboratory scale tests. In the final approval process, a toxicity test is conducted using discharged water from the system on the test-bed for a comprehensive evaluation.

*4. The G8 guidelines, for "approval of a ballast water management system" (D-3.1 Regulation), provide the requirements for proper design, structure and performance of the operation parameter for approval of a ballast water management system, and the supervisory agency of each country issues approval taking into account the IMO guidelines. In Japan, the Ministry of Land, Infrastructure, Transport and Tourism grants an approval, and land-based testing is included in the "ballast water management system pre-installation tests" required for the approval.

The content in this website is accurate at the time of publication but may be subject to change without notice.

Please note therefore that these documents may not always contain the most up-to-date information.

Please note that German, French and Chinese versions are machine translations, so the quality and accuracy may vary.