The initiative is making steady progress, and new connections continue to be formed.

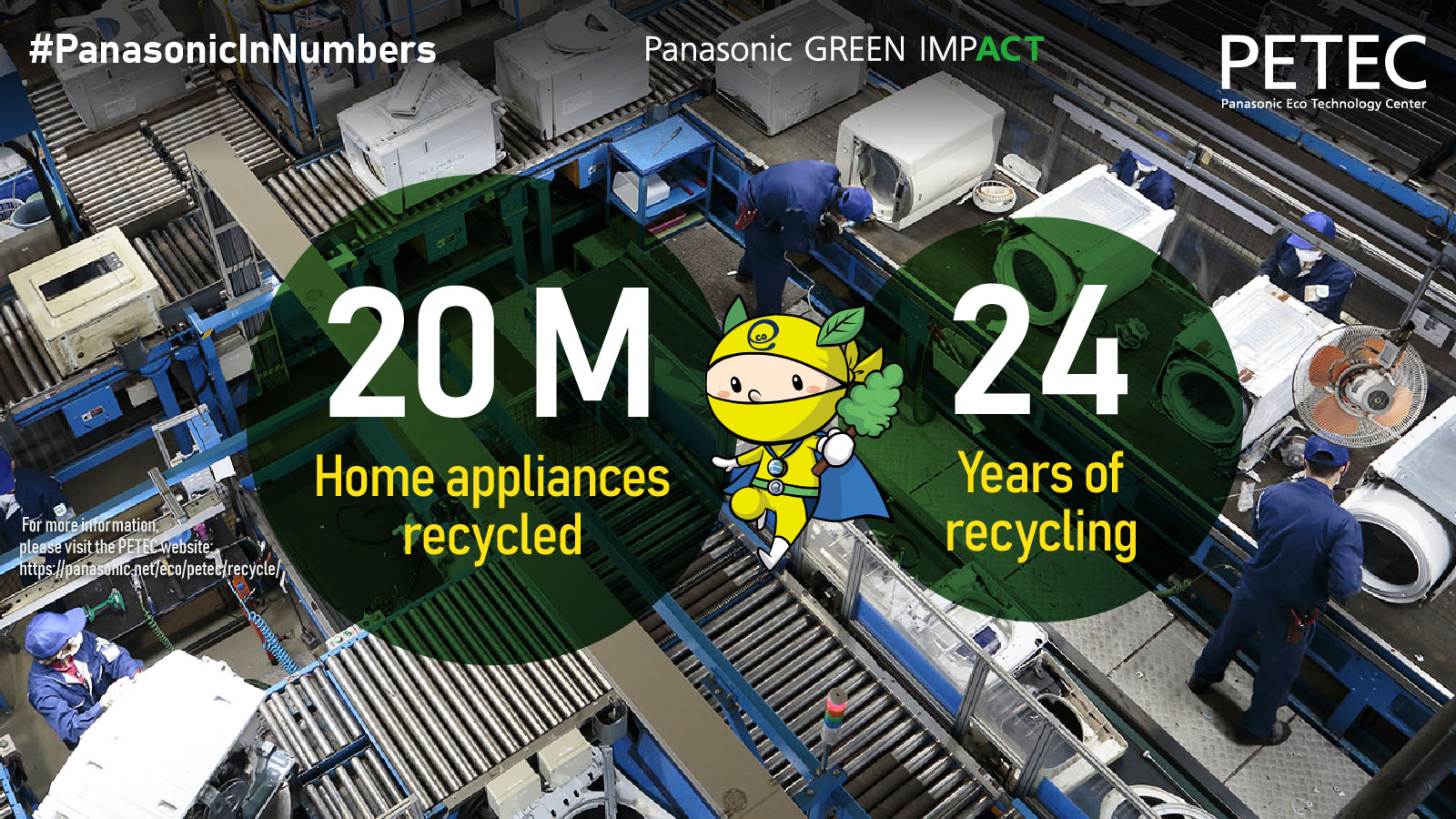

Wada: “All products have a lifespan. I want to create an ecosystem where products at the end of their lifespan can be upcycled.”

Climate change is an urgent global issue that the Panasonic Group is committed to help tackle. As in this project, each employee's awareness of an issue can be the starting point for decisive action and meaningful collaboration with co-creation partners.

This is merely one example of the initiatives that are taking place across the Panasonic Group. Individual ACTs, accumulated over time, can change the world. Panasonic Group will keep working to channel the impact of individual ACTs and utilize this power to achieve its climate change goals.