Feb 16, 2026

- Company

- Press Releases

- Technology

- R&D

Jun 27, 2023

Company / Press Releases

Automation of recycling plants with AI and robotics technology

Product dismantling technology for a recycling-oriented society

Osaka, Japan - Panasonic Holdings Corporation (PHD) today announced that its Manufacturing Innovation Division, in collaboration with Panasonic Eco Technology Kanto Co., Ltd. (PETEC Kanto) and Mitsubishi Materials Corporation, has developed an automatic dismantling system for the covers of air conditioner outdoor units, as a part of its circular economy activities. The system includes automatic dismantling equipment that uses robots to dismantle the covers of air conditioner outdoor units, and a dismantling database that stores information required for dismantling.

Under its long-term environmental vision, Panasonic GREEN IMPACT (PGI), Panasonic Group is striving to reduce CO2 emissions through its business activities, with the aim to contribute to the betterment of people's lives and to create a sustainable global environment. The development of this automatic dismantling system is a part of Panasonic's initiatives to promote circular economy activities under PGI.

[Background]

In light of the resource issues affecting the global environment in recent years, the United Nations has set "responsible consumption and production" as one of the Sustainable Development Goals (Goal 12), calling for a significant reduction in waste generation and the efficient use of limited resources on a global scale.

In April 2001, the Home Appliance Recycling Law was enforced in Japan, with the aim to reduce waste and to promote the efficient use of resources by recovering useful parts and materials from used home appliances, such as air conditioners, TVs, refrigerators/freezers, and washing machines/clothes dryers, from homes and offices. Due to such initiative, a large number of used home appliances has been brought to recycling plants. Today, 3.69 million air conditioners1 are sent annually to recycling plants where outdoor units are manually dismantled to recover parts, such as heat exchangers, compressors, and control boards, before being shredded and sorted.

As the amount of used appliances is expected to increase despite the decreasing labor force in Japan, there is a need to automate the dismantling processes at recycling plants to cope with manpower shortages in near future. The automation of the dismatling of air conditioner outdoor units, however, has been a challenge ; because the units usually come in various size and designs depending on the manufacturer, and are usually installed outdoors, exposed to dirt and rust.

[Solutions]

To tackle such issues, PHD has developed an automatic dismantling equipment that automatically removes screws and covers from air conditioner outdoor units using AI-based recognition technology. The equipment is also coupled with robot control technology that enables precise positioning control to replicate human manual work.

In cooperation with PETEC Kanto and Mitsubishi Materials, PHD also created a dismantling database that stores data on each model of outdoor air conditioner unit. The data is fed into the dismantling line in order to improve equipment utilization rates and lay the foundation for automating the dismantling process.

The automatic dismantling equipment for the covers of air conditioner outdoor units uses a camera that captures images of the outdoor units. By utilizing AI, the camera accurately detects screws even with dirt or rust on the units and then set the positioning of a robotic arm equipped with a screwdriver to remove the screws. A robotic grasping hand, which mimics human movement, then loosens and removes the cover. These features have enabled partial automation of the dismantling process.

The dismantling database leverages Mitsubishi Material's AI-OCR technology to read the label of each unit to obtain the data necessary for dismantling, such as the number and location of screws on the outdoor unit of the air conditioner, and then accumulates such data in the database. As a result, the outdoor unit models registered in the dismantling database can be dismantled more efficiently, with fewer unnecessary movements of the robot due to misidentification of screws. The more automatic dismantling equipment is used, the number of models stored in the database is expected to increase. This ultimately leads to the further advancement of the dismantling work in general.

After completing a pilot evaluation2 at PETEC Kanto in fiscal 2022, PHD will expand the range of models covered and improve the productivity of the system. As part of corporate activities for a sustainable society, PHD plans to expand the use of the automatic dismantling system to recycling plants within and outside the Panasonic Group throughout Japan in the future.

*1: Number of units in 2022 (Source: The Association for Electric Home Appliances)

*2: The pilot evaluation covered a limited number of manufacturers and models.

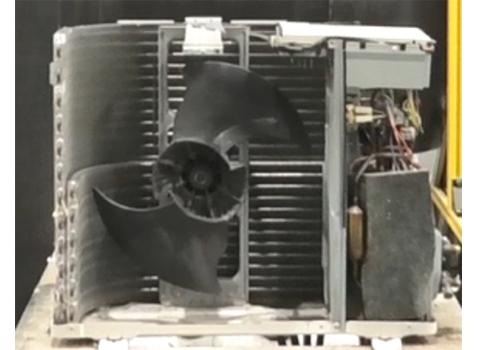

Collected air conditioner outdoor unit

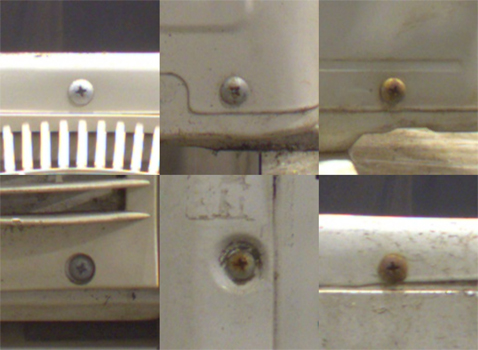

Screws in various conditions

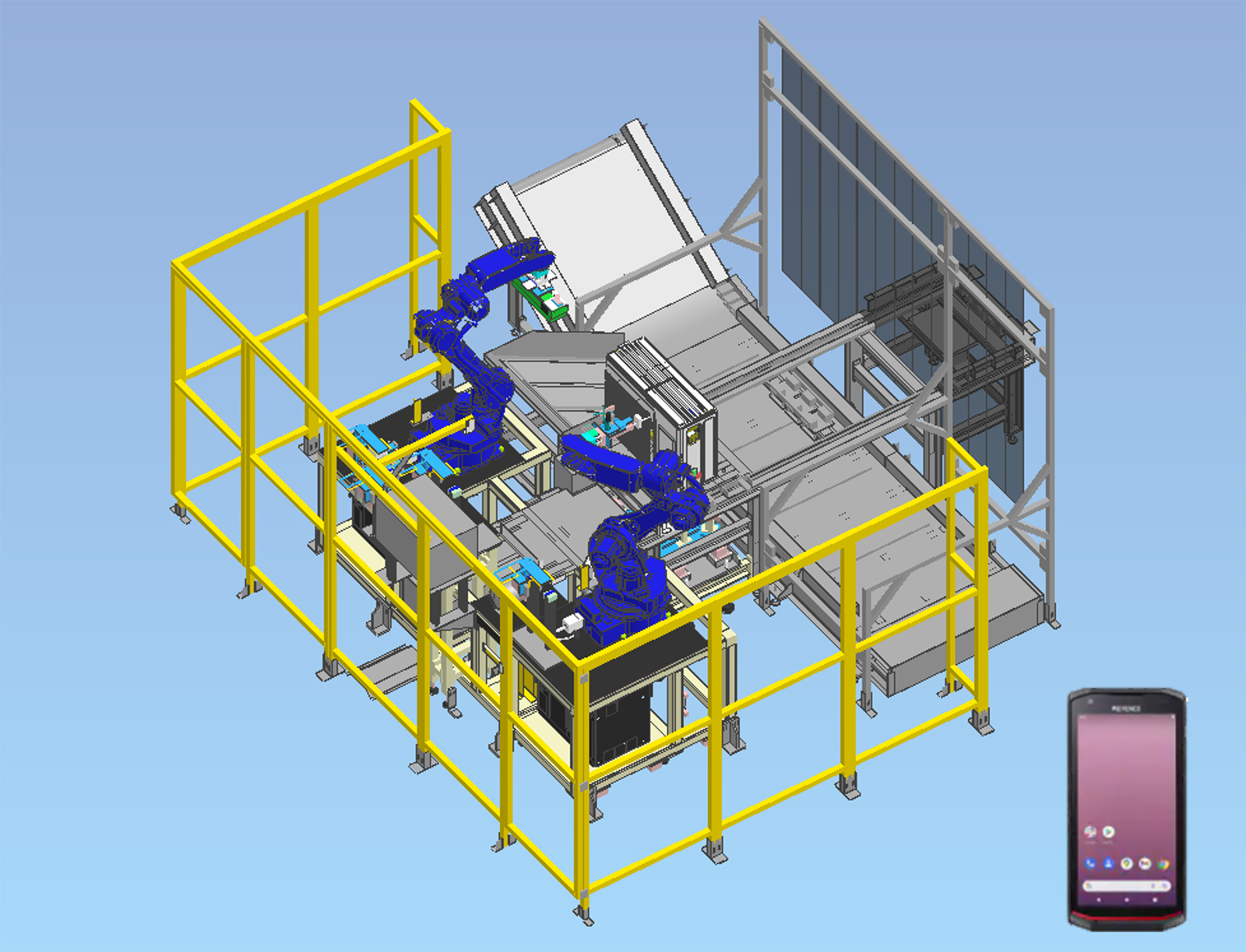

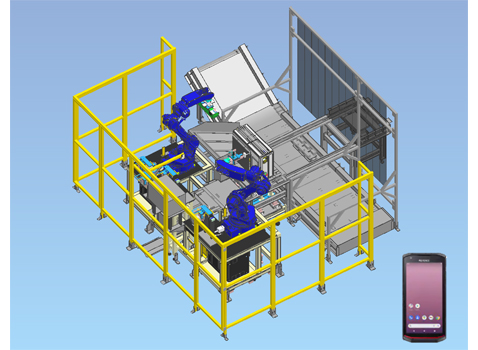

Automatic dismantling equipment and model number reader

Automatically dismantled outdoor unit

Recycling plant process automation, manufacturing equipment automation, and more

Promotion & Engineering Planning Department, Manufacturing Innovation Division

E-mail: midpress@ml.jp.panasonic.com

|

About the Panasonic Group Founded in 1918, and today a global leader in developing innovative technologies and solutions for wide-ranging applications in the consumer electronics, housing, automotive, industry, communications, and energy sectors worldwide, the Panasonic Group switched to an operating company system on April 1, 2022 with Panasonic Holdings Corporation serving as a holding company and eight companies positioned under its umbrella. The Group reported consolidated net sales of 8,378.9 billion yen for the year ended March 31, 2023. To learn more about the Panasonic Group, please visit: https://holdings.panasonic/global/ |

The content in this website is accurate at the time of publication but may be subject to change without notice.

Please note therefore that these documents may not always contain the most up-to-date information.

Please note that German, Spanish and Chinese versions are machine translations, so the quality and accuracy may vary.