Feb 13, 2026

- Products & Solutions

- Stories

- Panasonic GREEN IMPACT

- Hydrogen Energy Solutions

- Panasonic HX

- Europe and CIS

- Business Solutions

Dec 25, 2017

Products & Solutions / Press Releases

The capacitor is the industry's first 6.3mm diameter and 30G vibration acceleration resistant characteristics. It will be launched in January 2018. Their compact diameter and stability for vibration is suitable to ECUs in automotive.

Osaka, Japan - Panasonic Corporation announced today that it has commercialized an anti-vibration, surface-mounted conductive-polymer hybrid aluminum electrolytic capacitor [1] suitable for use in power circuits for automotive electric control units (ECUs) employed in hybrid electric vehicles, electric vehicles, and gasoline-powered vehicles. The company will launch the capacitor in January 2018.

With the growing demand for eco-friendly cars, energy efficiency and the need to comply with environmental regulation, more ECUs are being employed in cars. Mechanical and electrical in-vehicle components are also becoming integrated [2]. This trend has created a need for more compact ECUs combined with better resistance to vibration. The capacitors employed to stabilize the voltage of a power circuit for the ECU and eliminate electronic noise are therefore increasingly required to be smaller in size and to show better anti-vibration performance. The company launches the industry's first surface-mounted conductive polymer hybrid aluminum electrolytic capacitor which is only 6.3 mm in diameter and achieves resistivity of 30G high vibration acceleration.

Power circuits for high-performance ECUs incorporated in hybrid electric vehicles, electric vehicles, and gasoline-powered vehicles, mechanical-electrical-integrated ECU circuits

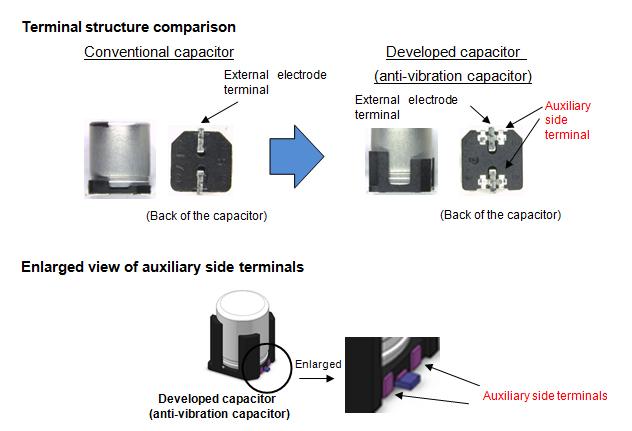

The pressure to reduce the size, weight and number of power train-type ECUs mounted in cars has led to a change in their placement from the engine compartment to the engine itself. This has increased the need for the capacitors incorporated in ECUs of this type to be small, high-capacitance, and extremely anti-vibration. Currently, most capacitors with superior anti-vibration performance are 8 - 10 mm in diameter. The industry, however, needs a smaller type. Leveraging our own auxiliary terminal structure, Panasonic has commercialized anti-vibration capacitor with a diameter of 6.3 mm that withstands vibration acceleration of 30G for the first time in the industry. This new capacitor will contribute to miniaturization of the ECU and provide better overall resistance to vibration.

The conventional ECU board mounting process requires anti-vibration measures, such as anchoring components with adhesives, to make the ECU resistant to vibration if using non-vibration-resistant components. The developed capacitor has achieved anti-vibration performance high enough to withstand a vibration acceleration of 30G, making such anti-vibration measures unnecessary, thus allowing customers to streamline their production processes.

This auxiliary terminal structure has auxiliary terminals positioned on the sides of the capacitor. This eases visual confirmation of auxiliary terminal soldering, ensures stable soldering properties, and enhances the ECU's overall vibration resistance.

| Product series | ZA, ZC, ZK |

|---|---|

| Size (diameter x height) | Diameter 6.3 mm x height6.1 mm Diameter 6.3 mm x height 8.0 mm |

| Vibration acceleration | 30G (294 m/ s²) |

| Frequency | 5 - 2000 Hz |

| Amplitude | 5 mm |

| Resistance to vibration (direction, time) | Vibration in the X, Y, and Z directions lasting for two hours each |

Panasonic Corporation is a worldwide leader in the development of diverse electronics technologies and solutions for customers in the consumer electronics, housing, automotive, and B2B businesses. Celebrating its 100th anniversary in 2018, the company has expanded globally and now operates 495 subsidiaries and 91 associated companies worldwide, recording consolidated net sales of 7.343 trillion yen for the year ended March 31, 2017. Committed to pursuing new value through innovation across divisional lines, the company uses its technologies to create a better life and a better world for its customers. To learn more about Panasonic:

http://www.panasonic.com/global

Panasonic Corporation

Tel: +81-(0)3-3574-5664

The content in this website is accurate at the time of publication but may be subject to change without notice.

Please note therefore that these documents may not always contain the most up-to-date information.

Please note that German, Spanish and Chinese versions are machine translations, so the quality and accuracy may vary.