Feb 24, 2026

- Products & Solutions

- Press Releases

Dec 21, 2020

Products & Solutions / Press Releases

- Industry-leading*1 low-loss materials contribute to the improved performance and downsizing of automotive ECUs

Osaka, Japan – Panasonic Corporation announced today that it has commercialized a surface mounted automotive power choke coil [1] suitable for power circuits in electronic control units (ECUs) installed in vehicles such as gasoline, diesel, and hybrid cars equipped with internal combustion engines, which are under pressure to meet the growing demand for improved fuel efficiency. The product features low loss, high withstand voltage, and high vibration acceleration-resistant characteristics, and will be mass-produced starting in February 2021.

With ever-tightening environmental regulations around the world, emission regulations for cars with internal combustion engines are becoming more stringent. In order to improve emissions performance, it is necessary for such cars to efficiently burn fuel to achieve complete combustion as much as possible. Accordingly, the direct fuel injection method [2] that directly injects fuel at high pressure into the cylinder has been adopted to facilitate highly efficient fuel combustion. Complete combustion requires fuel to be atomized and finely injected. For that purpose, it is indispensable for the coil used to boost the voltage of the injector drive unit of a direct injection engine to have the low loss and high withstand voltage characteristics in order to shorten its boost voltage recovery time. In addition, more automotive ECUs are being placed in the engine compartment, increasing the integration of mechanical and electronic in-vehicle components [3]. Moreover, this trend has created a need for automotive ECUs that can be installed in high-temperature environments under more severe vibration conditions and support larger currents. Panasonic has independently developed industry-leading low-loss magnetic materials with high withstand voltage to commercialize a surface-mounted automotive power choke coil that achieves the higher performance and downsizing of automotive ECUs.

Boosting DC/DC converter circuits [4] for gasoline, diesel, and hybrid cars, power circuits in highly functional automotive ECUs, and automotive ECU circuits integrated with mechanical drive components.

In accordance with environmental regulations, the internal combustion engines of cars are required to conform to further CO2 reduction requirements and emission controls, which has led to the introduction of fuel injection based on the direct injection method and the lean burn control [5] of fuel.

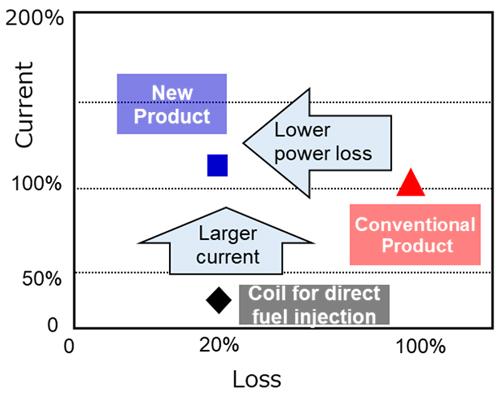

Power choke coils incorporated into automotive ECUs are used in boosting circuits; therefore, high withstand voltage characteristics are required in addition to lower power loss and greater downsizing features. Conventional products faced issues of unsatisfactory power loss and withstand voltage characteristics and were unable to allow large currents to flow. Panasonic has developed new low-loss magnetic materials capable of handling large currents with a high withstand voltage based on metal composite materials [6] using its in-house-developed metallic magnetic materials to commercialize a power choke coil with halved power loss and doubled high withstand voltage performance compared to conventional products. These features will contribute to the improved performance and downsizing of automotive ECUs.

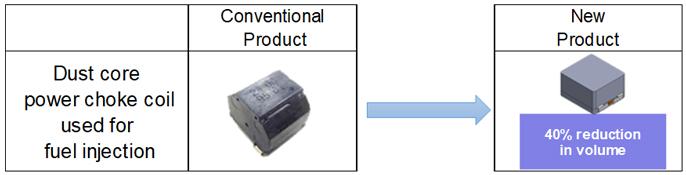

With the rapidly expanding computerization of cars, ECUs are being incorporated more frequently in the engine compartment and the engine itself, which requires the downsizing of ECUs. Accordingly, Panasonic has developed a high performance power choke coil using its in-house-developed magnetic materials and winding technology for forming coils with high accuracy. The size of the coil was reduced to 12.5 mm2, smaller than a comparable conventional product (14 mm2), and the volume was reduced by 40% compared to the company’s conventional power choke coil used for direct fuel injection. Additionally, the reduced number of coils required to be incorporated into ECUs due to the improved performance contributes to ECU space saving.

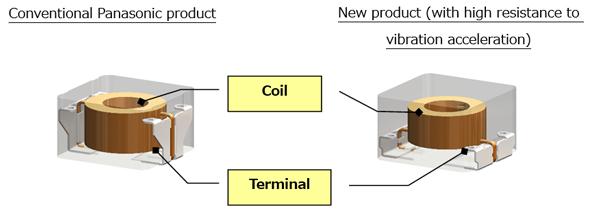

In conventional automotive ECU board mounting processes, reinforcement measures to fix components with bonding agents (adhesives) were necessary for ensuring the high vibration acceleration-resistant performance. This product employs Panasonic's original coil winding and forming technologies, which reduce the height of the terminal's pull-out position down to half compared to the company's conventional products. Positioning closer to the mounting circuit board have achieved excellent vibration resistant performance. This removes the need for anti-vibration reinforcement and contributes to the streamlining of the mounting process.

| Series | Shape W × D × H (mm) | Inductance [7]*1 | DC resistance [8] 20°C | Rated current*2 | Rated voltage |

|---|---|---|---|---|---|

| PCC-M1280MS | 14.0 × 12.5 × 8.0 | 40 μH | 41.0 mΩ | 5.9 A | 125 V |

Panasonic Corporation Brand Strategy Division Global Communications Office

https://news.panasonic.com/global/contacts/

Device Solutions Business Division, Industrial Solutions Company

https://industrial.panasonic.com/cuif/ww/contact-us?field_contact_group=2304&field_contact_lineup=1392&ad=press20201221

Low-loss Power Choke Coil for Automotive (Metal core type) MC

https://industrial.panasonic.com/ww/products-inductors/automotive-inductors/automotive-inductors/low-loss_pcc?ad=press20201221

Panasonic Corporation is a worldwide leader in the development of diverse electronics technologies and solutions for customers in the consumer electronics, housing, automotive, and B2B businesses. The company, which celebrated its 100th anniversary in 2018, has expanded globally and now operates 528 subsidiaries and 72 associated companies worldwide, recording consolidated net sales of 7.49 trillion yen for the year ended March 31, 2020. Committed to pursuing new value through innovation across divisional lines, the company uses its technologies to create a better life and a better world for its customers. To learn more about Panasonic: https://www.panasonic.com/global.

The content in this website is accurate at the time of publication but may be subject to change without notice.

Please note therefore that these documents may not always contain the most up-to-date information.

Please note that German, Spanish and Chinese versions are machine translations, so the quality and accuracy may vary.