Feb 27, 2026

- Products & Solutions

- Topics

- India, Middle East and Africa

- Business Solutions

- Operating Company

Mar 22, 2018

Products & Solutions / Press Releases

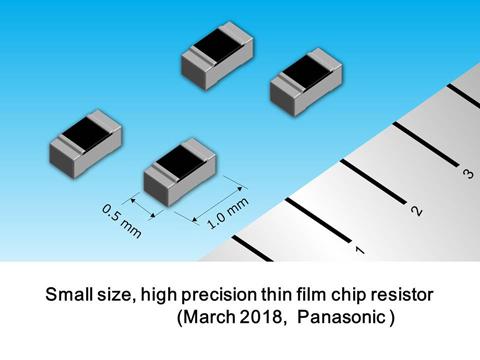

Panasonic Corporation has developed a 0402 size, high precision thin film chip resistor that helps increase accuracy and decrease electro-static discharges risk in automotive ECUs and industrial robots.

Osaka, Japan - Panasonic Corporation has developed a 0402 size, high precision thin film chip resistor that achieves the most robust electro-static discharge (ESD)[1] protection*1 in resistor field. Mass production is planned to start from June 2018. The resistor will help increase accuracy and decrease ESD risk in the power supply units and automotive electronic control units (ECUs), industrial robots, etc.

The need for anti-ESD design in ECUs has been growing with the ever-increasing use of electronics in vehicles. In addition, along with the development of autonomous vehicles as well as environmentally friendly vehicles that feature improved fuel efficiency, ECUs have become increasingly compact and accurate. For this reason, compact, high precision, and high anti-ESD performance resistors are required for such ECUs. The thin film chip resistor, which achieves the industry's most robust ESD protection while remaining compact and high precision, has been developed based on Panasonic's proprietary thin film formation technology.

| Automotive: | Control and power circuits in engine ECUs, hybrid electric vehicle (HEV) and EV inverters, anti-lock brake systems, and telematics communication units (TCUs) |

| Industrial: | Control circuits in industrial robots, precision machine tools, FA control equipment, measuring instruments, and servers |

Small size and high precision chip resistors are required for the miniaturization of ECUs as well as to achieve increased sensor accuracy needed in autonomous driving technologies. In addition, together with the increasing use of electronics in vehicles, sudden ESDs can cause malfunctions and breakdowns of equipment. ESD measures are therefore required. The structure of the resistive film in conventional compact thin film chip resistors is prone to instantaneous over-voltage occurrences such as ESDs, resulting in local high-loads. This, in turn, causes the resistors to break down more easily. The compact, high precision thin film chip resistor, which achieves the industry's highest ESD performance, was developed based on Panasonic's proprietary thin film formation technology in order to decrease local voltage loads due to over-voltage. In addition to providing highly accurate control of input and output signals in amplifier and control circuits, the company's new thin film chip resistor makes it possible to do away with some of the equipment and restrictions on handling that were necessary as part of the mounting process of thin film resistors in order to reduce ESDs.

In environments with wide temperature range, thermal stress due to the difference in the coefficient of linear expansion between the chip resistor and the mounting board is repeatedly applied, causing cracks in the solder fillets[3], eventually resulting in a variation in resistance. Long-term use was therefore an issue. By making use of Panasonic's proprietary electrode structure which incorporates a buffer layer inside the electrode, this new product suppresses crack propagation occurring in the solder fillets to achieve thermal shock resistance appropriate for automotive applications. It is suitable for equipment such as integrated electromechanical modules which require to be operated in environments that are subject to extreme temperature fluctuations or over long periods of time.

Sulfur compounds are present in various forms in the atmosphere: automobile exhaust gas, hot spring sulfur gas, etc. Exposing a chip resistor to sulfur compounds causes sulfidation of the electrodes, which may result in a variation of the resistance value. In recent years, demand for sulfidation-resistant resistors has been increasing in order to improve the long-term reliability and safety of various automotive and industrial equipment control circuits. By selecting electrode materials highly resistant to sulfidation and making use of its proprietary methods, Panasonic has developed a resistor that offers superior sulfidation resistance for improved reliability in control circuits. The resistor is also suitable for use in industrial robots that require sulfidation resistance.

| Series name | ERA2V Series | ERA3V Series | ERA6V Series |

|---|---|---|---|

| Chip size (mm) Chip size (inch) | 1005 0402 | 1608 0603 | 2012 0805 |

| Rated power [W] | 0.063 | 0.1 | 0.125 |

| Limiting element voltage [V] | 25 | 75 | 100 |

| Resistance range [Ω] | 47 to 100k | 47 to 330k | 47 to 1M |

| Resistance tolerance [%] | ± 0.05, ± 0.1 | ||

| Temperature coefficient of resistance (T.C.R.) [× 10-6/°C] | ± 5, ± 10, ± 15, ± 25 | ||

| Category temperature range [°C] | -55 to 155 | ||

Panasonic Corporation is a worldwide leader in the development of diverse electronics technologies and solutions for customers in the consumer electronics, housing, automotive, and B2B businesses. Celebrating its 100th anniversary in 2018, the company has expanded globally and now operates 495 subsidiaries and 91 associated companies worldwide, recording consolidated net sales of 7.343 trillion yen for the year ended March 31, 2017. Committed to pursuing new value through innovation across divisional lines, the company uses its technologies to create a better life and a better world for its customers. To learn more about Panasonic:

http://www.panasonic.com/global

Panasonic Corporation

Tel: +81-(0)3-3574-5664

The content in this website is accurate at the time of publication but may be subject to change without notice.

Please note therefore that these documents may not always contain the most up-to-date information.

Please note that German, Spanish and Chinese versions are machine translations, so the quality and accuracy may vary.