Jun 30, 2011

Press Release

Panasonic Develops Thermoelectric Tubes

for Compact Geothermal Electricity Generation

and Waste Heat Recovery

Osaka, Japan - Panasonic has developed innovative thermoelectric tubes especially suited for fluid heat source such as hot water and steam. The tubular shape enables direct and efficient heat transfer without additional heat exchangers, yielding high density of generated power. Panasonic's thermoelectric tube with simple, compact, and efficient features is an ideal solution for capturing unused or wasted heat from hot springs and factory.

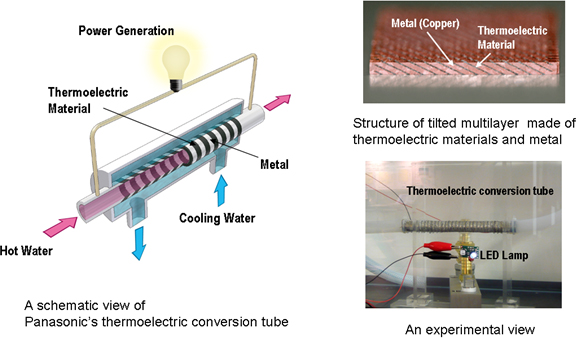

Thermoelectric technology is the direct energy conversion from heat into electricity and has attracted much attention as a renewable energy solution. Since conventional thermoelectric generators are complicated in structure and restricted in planar shape, they are difficult to scale-up and implement. Panasonic's thermoelectric tubes solve these problems by using unconventional phenomena called transverse thermoelectric effect, which takes place in tilted multilayer made of thermally-resistive thermoelectric materials and thermally-conductive metals. This effect makes it possible to control heat flow and electric current independently in materials, and realizes quite simple structure without complicated electric junctions and planar substrates.

The performance of power generation is strongly dependent on many parameters such as size of the tube and amount of heat source. Panasonic has developed the simulation technology to optimize the design of the thermoelectric tube in order to maximize the output electric power in accordance with surrounding conditions.

The thermoelectric tube is constructed by stacking conical rings of bismuth telluride as thermoelectric material and nickel as metal. Panasonic has developed processing technologies in fabricating conical rings of brittle thermoelectric materials and bonding rings with minimum parasitic electric and thermal losses.

The 10 cm-long fabricated thermoelectric tube using technologies introduced above can generate 1.3 W of electricity by running hot water of 90 °C inside, and cold water of 10 °C outside the tube. The power density corresponds to as high as 10 kW with only 1 m3 of volume. Development on system design, optimization in manufacturing and feasibility study are now under way or planned, with a view to realizing compact, efficient, and economical generators fueled by geothermal energy and waste heat in factories.

On this development, Panasonic holds 29 domestic patents and 12 overseas patents, including pending applications.

This development was partially presented at Electronic Materials Conference held in Santa Barbara, United States on June 22, 2011.

About Panasonic

Panasonic Corporation is a worldwide leader in the development and manufacture of electronic products for a wide range of consumer, business, and industrial needs. Based in Osaka, Japan, the company recorded consolidated net sales of 8.69 trillion yen (US$105 billion) for the year ended March 31, 2011. The company's shares are listed on the Tokyo, Osaka, Nagoya and New York (NYSE:PC) stock exchanges. For more information on the company and the Panasonic brand, visit the company's website at http://panasonic.net/.

Media Contacts:

- Global Public Relations Office

- Panasonic Corporation

- Tel: 03-6403-3040 Fax: 03-3436-6766

- Panasonic News Bureau

- Tel: 03-3542-6205 Fax: 03-3542-9018

Banner area begins from here.

The content in this website is accurate at the time of publication but may be subject to change without notice.

Please note therefore that these documents may not always contain the most up-to-date information.

Please note that German, French and Chinese versions are machine translations, so the quality and accuracy may vary.