Oct 29, 2024

- Products & Solutions

- Press Release

- Business Solution

- Automotives & Mobility

- Corporate Social Responsibility (CSR)

Oct 01, 2021

Products & Solutions / Press Release

- The new generator boasts the industry's best*1 electrical efficiency of 56%*2

Osaka, Japan - Panasonic Corporation today announced that it has developed a pure hydrogen fuel cell generator, which generates power through chemical reaction with high-purity hydrogen and oxygen in the air. The generator will be launched on October 1, 2021 for commercial use in Japan.

In recent years, with the acceleration of initiatives to realize a decarbonized society, several countries and regions around the world have declared their intention to reduce their overall emissions of greenhouse gases to zero by 2050, in other words, achieving carbon neutrality. In order to achieve the goal, it is indispensable to introduce renewable energy sources such as solar, wind, geothermal, hydro, and biomass power. However, power generation using solar and wind has drawbacks such as large output variations depending on weather condition and the lack of capabilities to adjust power generation to cope with demand. Moreover, such power generation requires a system to store surplus power in storage batteries or via other methods, and compensate for power shortages.

Accordingly, hydrogen is attracting interest as a next generation energy source. Hydrogen is the most abundant substance not only on earth but also in the universe, and can be used as thermal energy and electric power through combustion and chemical reaction without emitting CO2 in the process. Hydrogen is also superior in terms of storing and utilizing energy because electricity from renewable energy can be converted into hydrogen through electrolysis using surplus power and stored stably for a long period of time. Against this backdrop, the use of hydrogen is expected to expand rapidly.

In 2009, Panasonic launched the world's first household fuel cell cogeneration system, ENE-FARM*3, which uses hydrogen extracted from natural gas to generate power. With more than 10 years, the company has evolved ENE-FARM by improving its electrical efficiency and operating time, as well as making it more compact. At the same time, in anticipation of the arrival of the hydrogen society, Panasonic has also been doing in parallel the research and development of pure hydrogen fuel cell generators, to which hydrogen is directly supplied from the outside as fuel to generate power. The company has conducted field tests with such generators at various places in Japan, starting in 2012 at Yume Solar Kan Yamanashi, a facility promoting renewable energy in Kofu City, Yamanashi Prefecture, central Japan.

Technology coming from the development of ENE-FARM has been applied to this pure hydrogen fuel cell generator. For example, by adopting the common stack unit, a key device of fuel cell which is used in ENE-FARM, the new product offers stable performance of power generation and achieves the industry's best*1 electrical efficiency of 56%*2. As this new generator is targeted for commercial use, its power output has been enhanced to 5 kW, which is more than seven times more than 700 W power output of a household fuel cell, ENE-FARM. Moreover, the power output can be scaled up according to demand by connecting and controlling multiple generator units. In addition, by taking advantage of its lightweight and compact housing, this generator can be flexibly adapted to various installation conditions, including the rooftop and in narrow spaces.

Panasonic will dub its pure hydrogen fuel cell generators "H2 KIBOU*4" in the future, with the company's KIBOU, which means "hope" in Japanese, to realize a hydrogen society.

Panasonic will contribute to the realization of a decarbonized society by proposing new options for expanding the introduction of renewable energy that fully utilizes hydrogen.

A single unit can generate 5 kW power, which is suitable for the demand of small-scale commercial facilities. Moreover, connecting and controlling multiple generator units can increase the power output according to demand. Furthermore, by connecting the product to a dedicated PC application, it allows the system to be remotely controlled to display the power output and conditions, turn the power generation ON and OFF, and send error notifications. One PC allows the simultaneous connection of up to 10 units (50 kW). Further, by integrating 10 units into one level unit, MW-class power output can also be possible.

Image of generators installed on the rooftop of a building

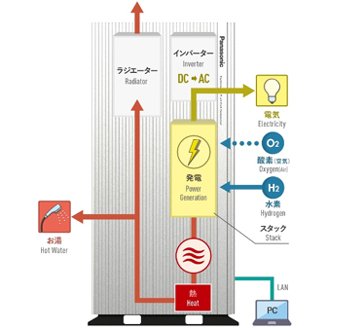

Image of generators installed on the rooftop of a building Overview of the pure hydrogen fuel cell generator structure

Overview of the pure hydrogen fuel cell generator structureHydrogen is directly supplied to pure hydrogen fuel cell generators, which require no fuel processing device (for extracting hydrogen from natural gas), a key device of ENE-FARM. As a result, it is possible to convert efficiently from hydrogen to electric power, thereby allowing the product to achieve high electrical efficiency of 56%*2, the industry's best*1 for a pure hydrogen fuel cell generator. The higher electrical efficiency leads to the reduction of the amount of hydrogen use, therefore contributing to the reduction of total running cost.

By connecting a hot water storage unit (recommended product) with the product, heat generated from fuel cell can be converted into hot water for use. The generator has achieved the total energy efficiency of 95% including the heat recovery, thereby allowing the effective use of energy without waste.

The use with a resistor unit (recommended product) and a startup power supply unit enables the product to generate power even during power outage. By connecting these units with the product which are designed for power outage users can continue to generate power and use up to 2.5 kW power for 120 hours even during a power outage. The product can generate power during power outage simply through the supply of hydrogen, thereby contributing to business continuity planning (BCP).

The product can be started in an approximately one minute, which is useful for responding to peak cut control when a quick response from generators is required.

| Type of fuel cell | Polymer electrolyte type (PEFC) | ||

|---|---|---|---|

| Model number | FC-5KLR1HS | ||

| Environ- ment |

Type of gases | Pure hydrogen (Hydrogen density : more than 99.97%) | |

| Gas supply pressure | 50 kPa | ||

| Installation environment temperature | -10°C to 40°C (Assuming that the product is always energized) | ||

| Installable altitude | Up to 500 m above sea level | ||

| Installation | Dimension | 834 mm (W) × 417 mm (D) × 1,766 mm (H) (Including the design panel) |

|

| Operating mass | 205 kg (Including the design panel) | ||

| Installation distance (Maintenance space) |

Front: 600 mm | ||

| Back: 600 mm | |||

| Top: 1,000 mm | |||

| Left and right sides: 600 mm | |||

| Basic perform- ance |

Power output | 5,000 W (Output during a power outage: 2,500 VA) | |

| Output voltage | 1 φ 3 W 200 V AC (During self-operation: 1 φ 2 W 100 V AC) | ||

| Power generation time | Up to 120 hours | ||

| Power Consumption | Maximum value during normal operation | Up to 155 W | |

| Freezing prevention heater | Freezing prevention heater: 578 W | ||

| Without load (During standby) | Up to 30 W | ||

| Gas consump- tion |

When generating the rated power | 49.6 NL/m | |

| When generating the maximum power | 51.6 NL/m | ||

| Thermal output | Heat recovery temperature | Approx. 60°C | |

| Thermal output when generating the rated power | 3,480 W | ||

| Efficiency | Electrical efficiency (LHV/HHV) | 56%/47.3% | |

| Heat recovery efficiency (LHV/HHV) | 39%/32.9% | ||

| Starting time | Approx. 1 minute (Approx. 7 minutes to reach the rated output) | ||

| Normal stopping time | Approx. 30 seconds | ||

| Drainage water | Approx. 1.2 L/h | ||

| System interconnection | Certification acquired | ||

| With voltage rise suppression | |||

| With reverse power flow | |||

| Supports independent operation detection | |||

| Maintenance | Every 18,000 hours of energization (Maintenance A) After 35,000 cumulative hours of power generation (Maintenance B) After cumulative 54,000 hours of power generation (Maintenance C) |

||

Panasonic Corporation Brand Strategy Division Corporate PR Department

https://news.panasonic.com/global/contacts/

Panasonic Corporation is a global leader developing innovative technologies and solutions for wide-ranging applications in the consumer electronics, housing, automotive, and B2B sectors. The company, which celebrated its 100th anniversary in 2018, operates 522 subsidiaries and 69 associated companies worldwide and reported consolidated net sales of 6,698.8 billion yen for the year ended March 31, 2021. Committed to pursuing new value through collaborative innovation, the company uses its technologies to create a better life and a better world for customers. Learn more about Panasonic: https://www.panasonic.com/global.

The content in this website is accurate at the time of publication but may be subject to change without notice.

Please note therefore that these documents may not always contain the most up-to-date information.

Please note that German, French and Chinese versions are machine translations, so the quality and accuracy may vary.