Apr 09, 2024

- Products & Solutions

- Press Release

- Business Solution

- Media and Entertainment

Oct 18, 2016

Products & Solutions / Press Release

Panasonic's new product, which exhibits exceptional bending resistance as well as improved input sensitivity and display visibility, will be available in commercial quantities beginning December 2016.

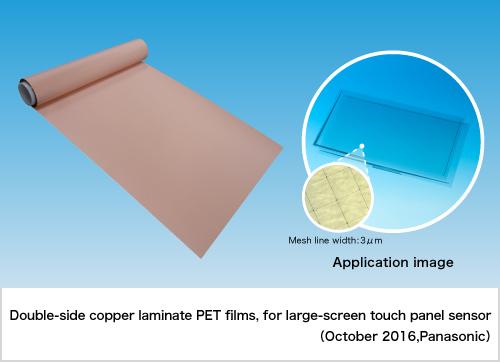

Osaka, Japan - Panasonic Corporation announced today that it has launched "Double-side copper laminate polyethylene terephthalate (PET) films[1]" suitable for large-screen touch panel sensor[2] (Product Number: R-H825). This product is designed for large-format touch panel sensors used in many electronic products like electronic blackboards, digital signage, and amusement devices.

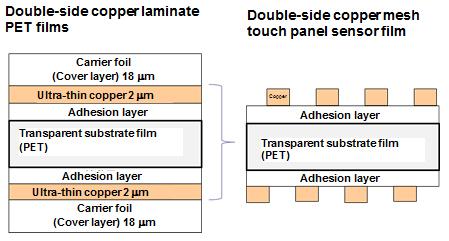

Touch panel display manufacturers are striving to improve qualities of large format touch panels. One approach is to increase the sensor performance to help maximize the viewing area, enhance the ease of use for both pen and multi-touch inputs, and improve outdoor and indoor visibility even as display resolution increases to 4K and beyond. During the manufacturing process, large touch panel sensors may experience bending due to their size and weight. The resultant stresses on the conductors increase the risk of cracks or breaks in the sensor's copper wires that can result in an increase in electrical resistance or even complete failure of the wire. By combining a unique resin chemistry with proprietary thin-layer copper laminating technology, Panasonic has developed the new R-H825 "Double-side copper laminate polyethylene terephthalate (PET) films". This product exhibits excellent bending-resistance that reduces the risk of wire breakage, even in the largest displays. Additionally, low resistance copper ensures superior input sensitivity and a narrow mesh pattern enables high display visibility. Copper foil on both sides of the transparent PET improves mesh alignment and eliminates the need to use two separate single-sided conductive films.

Touch panel sensors used in electronic blackboards, digital signage, amusement devices, etc.

During the manufacturing process, large touch panel sensors may experience bending due to their size and weight. The stress from bending increases the risk of cracks or breaks in touch sensor's copper wires that can result in an increase in electrical resistance or the complete failure of the wire. By combining a unique resin chemistry with proprietary thin-layer copper bonding technology, Panasonic has developed the new R-H825 "Double-side copper laminate polyethylene terephthalate (PET) films". This product exhibits excellent bending-resistance that reduces the risk of circuit breakage and high resistance failures, even in large displays

There is an increasing demand for multi-touch finger and pen touch inputs for large-format panels. The Panasonic R-H825 enables high input sensitivity by adopting low-resistance copper foil as the conductor. The surface resistance of this product is approximately 1/50 to 1/100th that of sensor film materials using ITO (indium tin oxide) or silver conductors. This extremely low resistance enables high-speed multi-point input and ensures smooth pen operation.

As displays adopt higher definition, sensor films with thinner wiring are required. Until now, low adhesion between PET film and the copper pattern of conventional sensor films has severely limited the thinness of the conductor layer. The R-H825 enables low fine patterning by using Panasonic's unique composite material development technology to significantly increase the bond strength between the PET and the copper pattern. This increased adhesion enables dramatically finer wiring patterns, which in turn improve display visibility. (Panasonic can also provide this material as a copper mesh sensor film.) The manufacturing of traditional touch panels requires the highly accurate positioning of two single-sided sensor films prior to bonding them together. Precise positioning becomes increasingly difficult as larger screen sizes are designed. The Panasonic R-H825 has a conductive copper foil layer on both sides which eliminates the need to bond two films and achieves high positional accuracy of the X and Y layers and simplifying the manufacturing process.

Panasonic Corporation is a worldwide leader in the development of diverse electronics technologies and solutions for customers in the consumer electronics, housing, automotive, enterprise solutions and device industries. Since its founding in 1918, the company has expanded globally and now operates 474 subsidiaries and 94 associated companies worldwide, recording consolidated net sales of 7.553 trillion yen for the year ended March 31, 2016. Committed to pursuing new value through innovation across divisional lines, the company uses its technologies to create a better life and a better world for its customers. To learn more about Panasonic: http://www.panasonic.com/global.

Panasonic Corporation

Tel: +81-(0)3-3574-5664 Fax: +81-(0)3-3574-5699

The content in this website is accurate at the time of publication but may be subject to change without notice.

Please note therefore that these documents may not always contain the most up-to-date information.

Please note that German, French and Chinese versions are machine translations, so the quality and accuracy may vary.