Jul 19, 2024

- Products & Solutions

- Blog Posts

- EV Solutions

- Business Solution

- Operating company

- Electronic Materials/Devices

May 15, 2023

Products & Solutions / Press Release

Concurrently achieving the industry's first(*1) high-thermal conductivity (2.7 W/m・K(*2)) and multilayering of electronic circuit boards

Contributes to the miniaturization of equipment by solving thermal issues in high-output xEVs and industrial equipment

Osaka, Japan - Panasonic Industry Co., Ltd. (Headquarters: Kadoma, Osaka; Representative Director, President, CEO: Shinji Sakamoto) announced today that it has developed the high-thermal conductive film R-2400 for multilayer circuit boards.

In recent years, electric vehicles (xEVs) have become increasingly popular due to growing interest in environmental issues. To improve the energy efficiency of electric vehicles, batteries, power supply modules, and drive units have become even more powerful. This increases the need for power semiconductors such as SiC and GaN, posing significant challenges for the thermal management of equipment. In addition, weight reduction and the miniaturization of power supply modules and drives are required to increase the cruising range of electric vehicles as well as improve passenger comfort by expanding vehicle interior space.

Accordingly, Panasonic Industry has developed the high-thermal conductive film R-2400 for multilayer circuit boards. The film has achieved industry firsts in both high-thermal conductivity of 2.7 W/m・K and excellent resin flowability that enables the multilayering of circuit boards.

The new product mitigates the effects of heat generated by power semiconductors and can be used in multilayer circuit boards?something difficult to achieve with conventional high-thermal conductive materials. It will also be appropriate for use in component-embedded circuit boards and those with thick copper foil. These features contribute to the reduction of power consumption (electricity costs) of electric vehicles and the reduction of CO2 emissions because of their effect on weight reduction and the miniaturization of power supply modules and drives.

(*1) As electronic circuit board materials and films for multilayer circuit board materials. Panasonic Industry's data as of May 15, 2023

(*2) Measured with the laser flash method

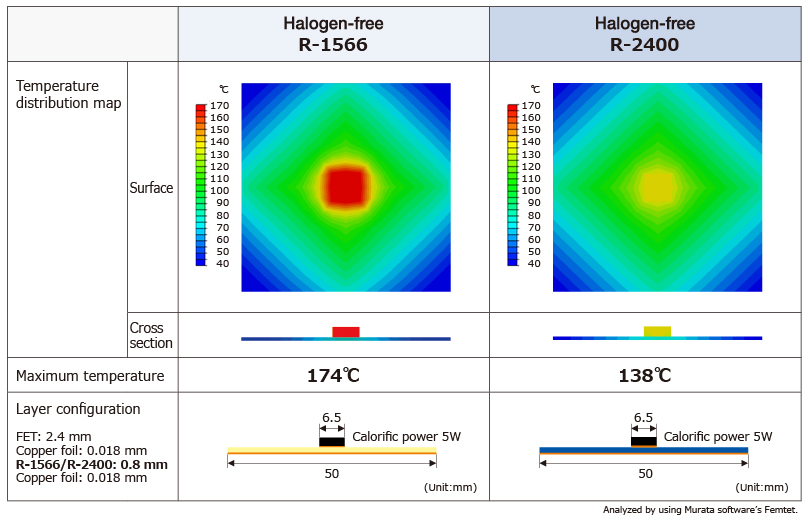

By utilizing high-thermal conductivity technology that employs inorganic filler design know-how[1], the film improves the heat dissipation of the entire electronic circuit board, contributing to the heat mitigation of power semiconductors. This helps reduce the number of thermal management components such as heat dissipation fins and cooling fans, which, in turn, contributes to the miniaturization of equipment.

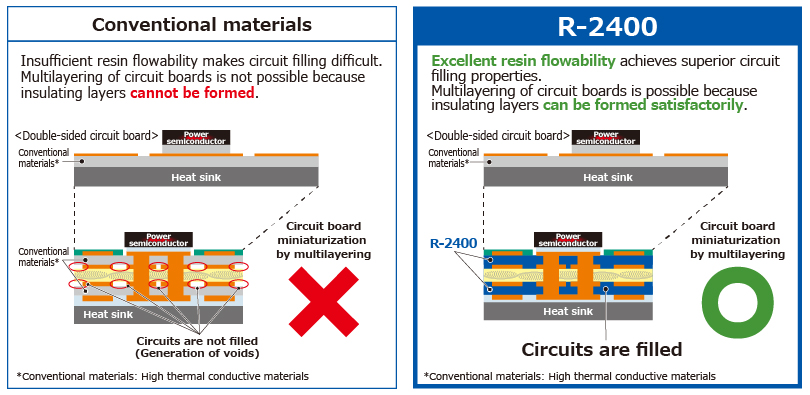

Figure 1 Comparison of thermal conductivity

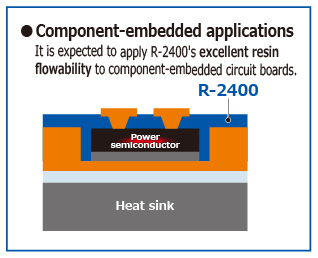

By designing the optimal balance of inorganic fillers and insulating resins, the film has achieved excellent resin flowability. This allows for the use of high-thermal conductivity materials in multilayer circuit boards, which was previously difficult in terms of circuit filling properties and insulation reliability. The product will also contribute to the further miniaturization of equipment in the future through the development of applications for component-embedded circuit boards and thick copper circuits. In addition, since the film can be utilized in the processing of general electronic circuit boards, it is expected to reduce the process load, with batch molding in combination with prepregs also being possible.

Figure 2 Superiority of R-2400: Miniaturization of circuit boards by multilayering (cross-sectional view)

Figure 3 Proposed other applications (cross-sectional view)

Panasonic Industry's unique resin design and compounding technology has achieved higher heat resistance of materials. The film can withstand heat generated by power semiconductors and can be used in high-temperature environments, including vehicle-mounted applications.

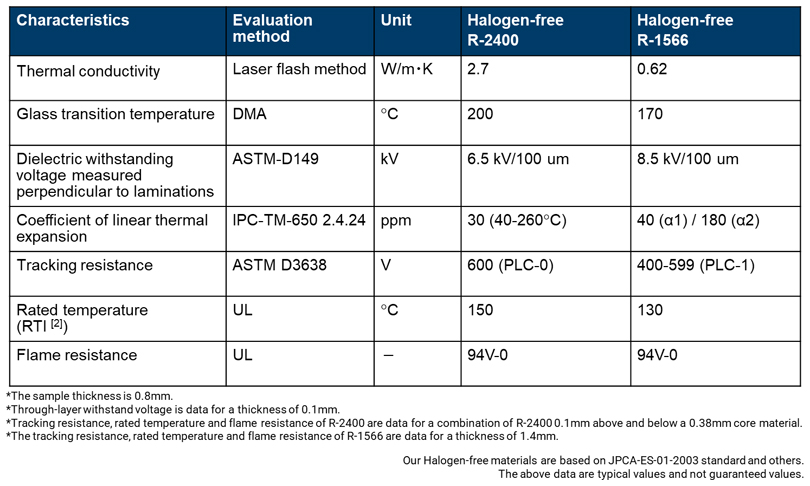

Please note that this product can be used together with Panasonic Industry's halogen-free glass epoxy multilayer circuit board materials R-3566D (certified to meet the UL-specified rated temperature of 150°C).

Multilayer circuit boards and component-embedded circuit boards used for core power supply components that require heat management measures (vehicle chargers, power supplies for railroads, power conditioners for photovoltaic power generation, inverters, step-up converters, and more)

Model number: R-2400

Lineup: 100 μm, 150 μm

Currently capable of mass production and sample shipment

May 24 to 26, 2023: Automotive Engineering Exposition 2023 at PACIFICO Yokohama

*Online exhibition: Wednesday, May 17 to Wednesday, June 7, 2023

[1] Inorganic filler design

This is technology related to the control of the types and amounts of thermally conductive inorganic fillers, and the method of mixing them with organic resins. The technology is indispensable for improving the thermal conductivity of materials.

[2] The RTI (Reference Thermal Index) refers to an index of a material's ability to maintain specific physical properties (physical, electrical, etc.) when exposed to high temperatures for a long period of time.

Specified by UL746B (IEC60216), the RTI of a material indicates the temperature at which the initial physical properties decrease to 50% after 60,000 hours.

Electronic Materials Business Division, Panasonic Industry Co., Ltd.

https://industrial.panasonic.com/cuif/ww/contact-us?field_contact_group=2343&field_contact_lineup=3249

Introduction of Electronic Materials by Panasonic Industry Co., Ltd.

https://industrial.panasonic.com/ww/electronic-materials

Panasonic Industry Co., Ltd. Website

https://www.panasonic.com/global/industry

|

About Panasonic Industry Co., Ltd. A global leader in developing innovative technologies and solutions for wide-ranging applications, the Panasonic Group switched to an operating company system on April 1, 2022 with Panasonic Holdings Corporation serving as a holding company and eight companies under its umbrella. |

The content in this website is accurate at the time of publication but may be subject to change without notice.

Please note therefore that these documents may not always contain the most up-to-date information.

Please note that German, French and Chinese versions are machine translations, so the quality and accuracy may vary.