In August 2017, Panasonic conducted joint research with the Kyoto University, Institute for Frontier Medical Science to develop and market an automated cell culture system for iPS cells. In addition to changing the culture medium on a daily basis, this device moves proliferated cells into new culture dishes at precisely the right timing, all automatically. The development of this device allows researchers to proceed with their work without being having to deal with laborious, time-consuming work. As a result, considerable acceleration of research into regenerative medicine and development of new drugs can be expected.

iPS Cells Hold Unlimited Possibilities for Contributing to the Future of Mankind

Discovered in 2006, iPS cells are pluripotent stem cells (similar to fertilized eggs that can form various tissues and organs). They were discovered and produced by a Kyoto University Group led by Professor Shinya Yamanaka, which resulted in Professor Yamanaka's receipt of the 2012 Nobel Prize in Physics and Medicine.

iPS cells, which are expected to play an active role in regenerative medicine and discovering the causes and suitable drugs for various diseases, are attracting worldwide attention and prompting continual research. This research requires a large number of cells, but, compared with other, ordinary cells, iPS cells demand a specialized culturing process with highly advanced techniques.

Culturing Places a Burden on Researchers

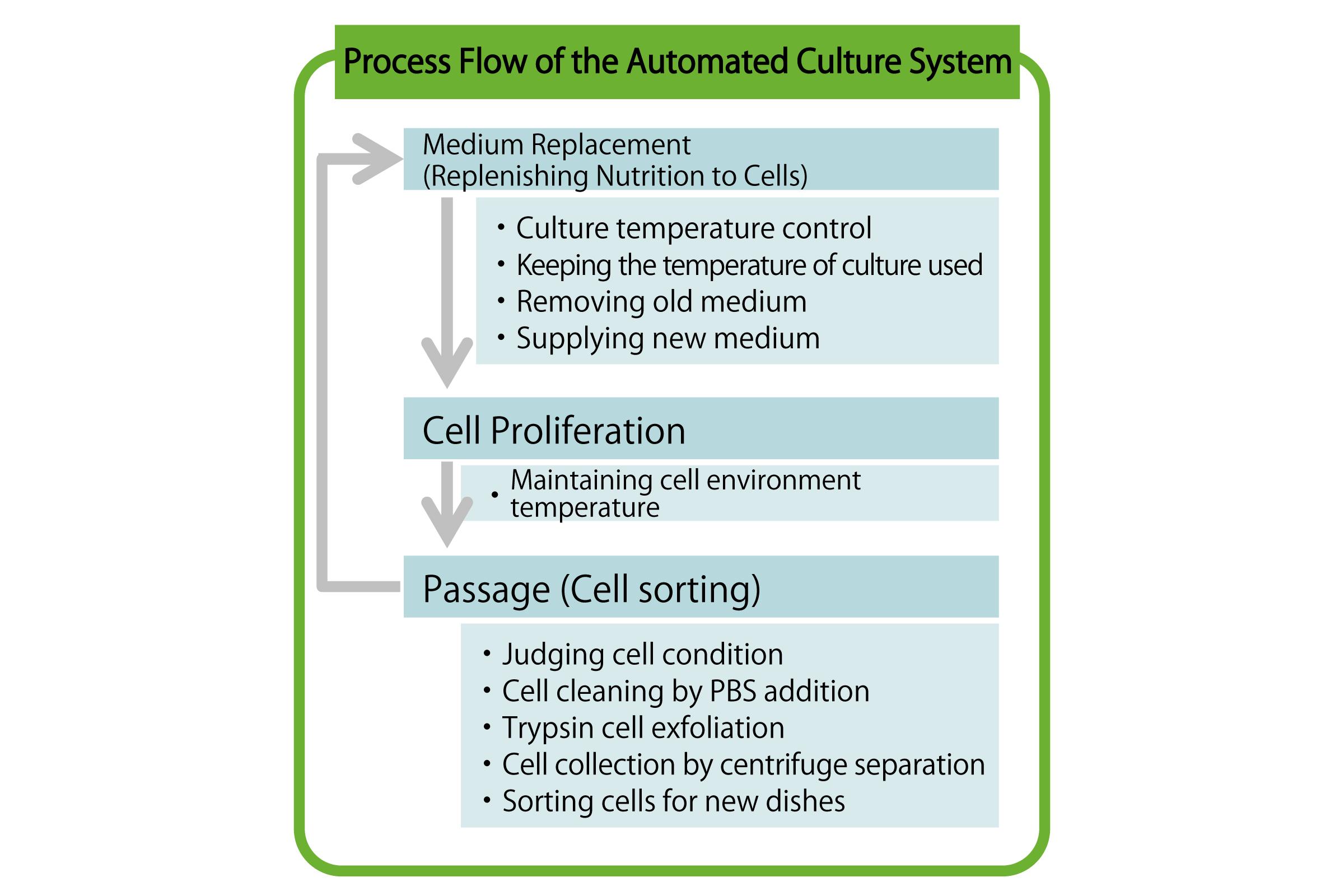

Researchers require 6 months to 1 year of training to be able to cultivate iPS cells properly. The culture medium must also be changed on almost a daily basis (removing the old culture medium and injecting a new culture medium). Passages, in which cells are carefully sorted, take place every three days. This process uniformly disseminates the proliferated cells into multiple culture vessels according to the desired size and density. Since the researchers could hardly get any rest, there was a pressing need for an automated cell culture system for iPS cells.

Dr. Shuhei Kanagaya of the Kyoto University, Institute for Frontier Medical Science (at the time of development)

Device Development Began with the Question, "What are Cells?"

A device was needed to do replace the manual work of the researchers and continuously provide cells of the same quality. To meet this need, Panasonic began development work with the researchers at the Kyoto University, Institute for Frontier Medical Science in 2013. According to Norihiro Shibata, the Chief Technician who led the Panasonic team, development began by asking, "What are cells?" "So the professors at Kyoto University kindly explained everything to us, from A to Z. We kept a video record of everything about cell culturing and thought about how that may be translated into a device. " In all, the development took four years. Panasonic's accumulated know-how of creating production facilities, image processing technology, robotic technology, and other technology was applied to the development of this device.

An Automated Device That Reproduced the Techniques of Skilled Cultivators

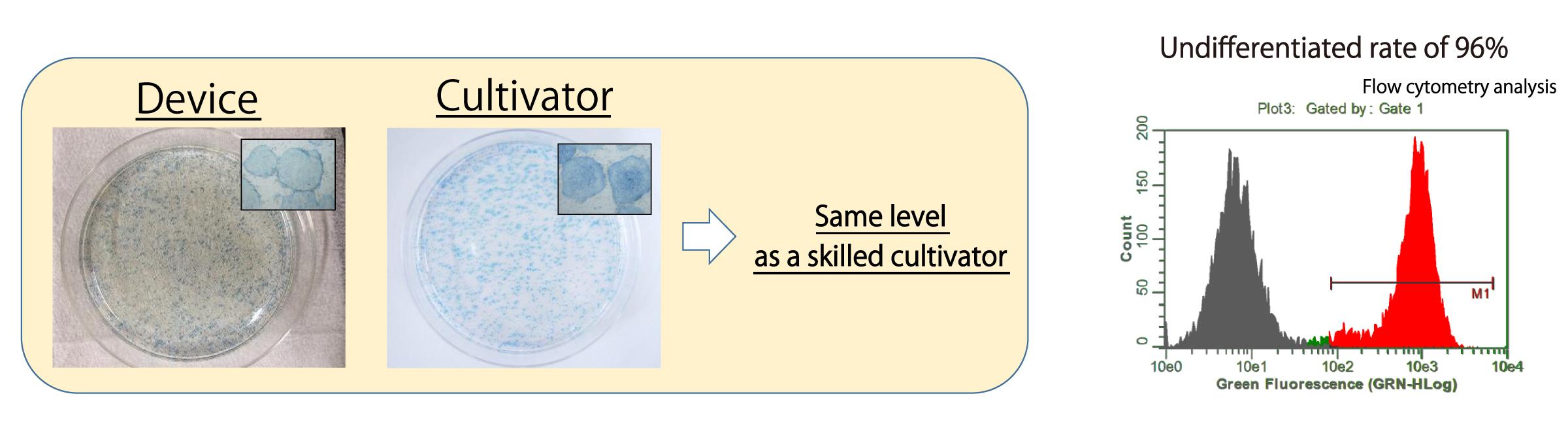

The finished automated cell culture system for iPS cells reproduced the subtle movements of skilled cultivators while greatly exceeding the levels of accuracy and stability. In a 20-passage test over a period of approximately 60 days, the device achieved an undifferentiated rate (a success rate for iPS cell culture) of 96%.

The automated cell culture system for iPS cells jointly developed by Kyoto University and Panasonic.

The automated cell culture system for iPS cells faithfully reproduces the pipette infusion and suction and other movements of highly skilled cultivators.

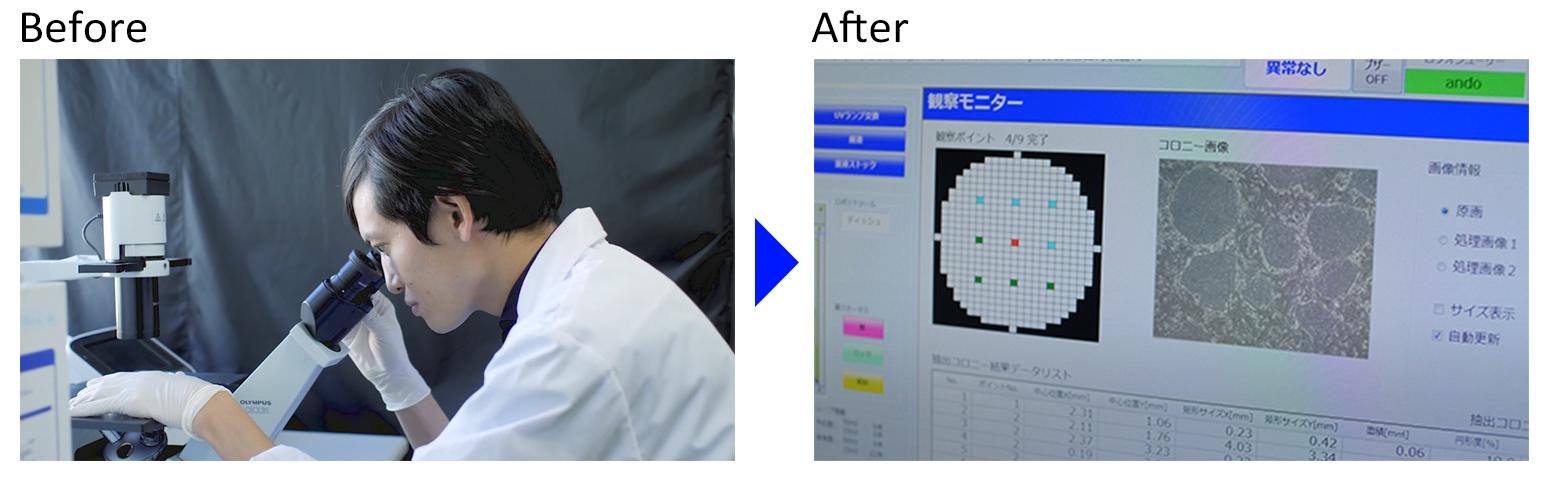

The timing for the passage process was previously determined by researchers using a microscope. The automated cell culture system for iPS cells uses image processing and analysis of an image from an optical microscope to automatically determine the timing and execute the passage.

The Future of the Automated Cell Culture System for iPS Cells

iPS cells are expected to play an active role in uncharted areas of medicine, such as physical wounds caused by intractable diseases and injuries. The completion of the automated cell culture system for iPS cells enables providing a steady supply of the high-quality cells that are essential for this research. Accordingly, researchers will be able to devote more efforts to activities that will lead to progress of regenerative medicine and development of new drugs.

Dr. Shuhei Kanagaya of the Kyoto University iPS Cell Research Center explains it as follows: "By incorporating Panasonic technologies, we can get results far more accurate than the human eye. We would like to deliver new treatments using iPS cells to as many patients as possible, as soon as possible."

Features of Panasonic's Automated Cell Culture System for iPS Cells

Automating the iPS cell cultivation from the replacement of the culture medium to the passage process

Continuously supplying iPS cells under the condition of minimized manual steps

Compact size, replaceable for a clean bench

Suitable for lab rooms with easy installation and compact design

Cultivation possible at the same level as a skilled cultivator

Approx. 20 passages in 60 days. Undifferentiated rate of 96% (healthy cells cultivated)

No skill fluctuation or contamination

Highly accurate robotic work, low risk of fluctuation and contamination

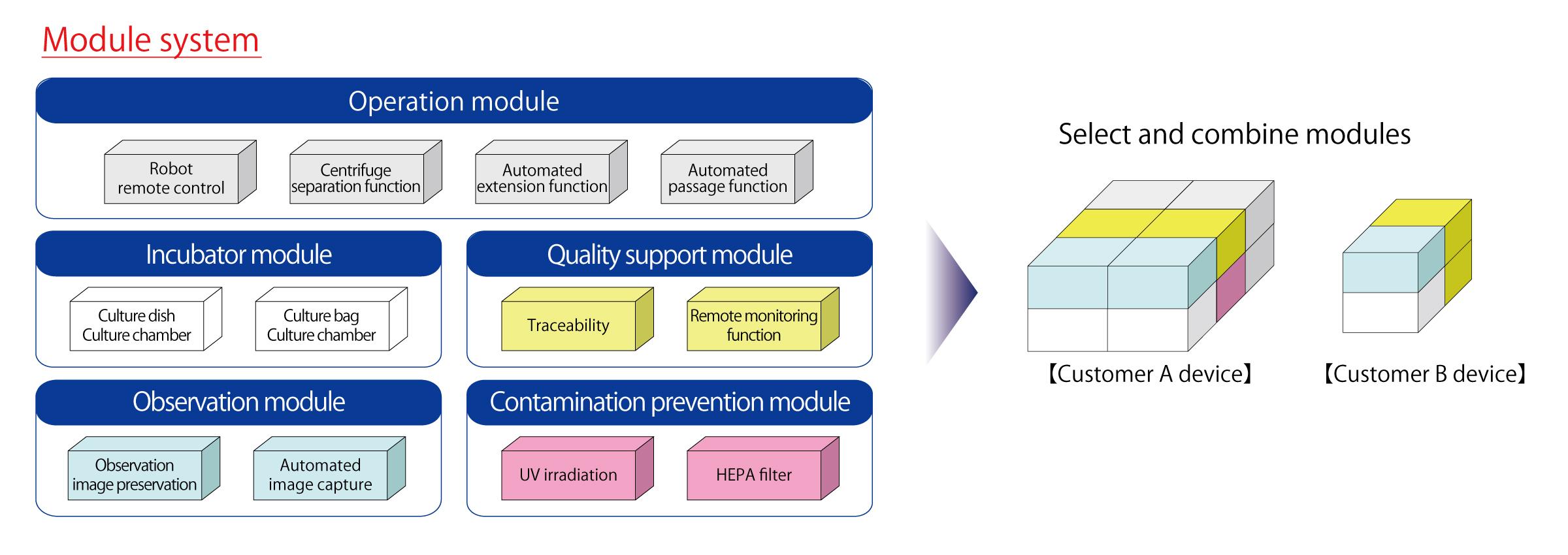

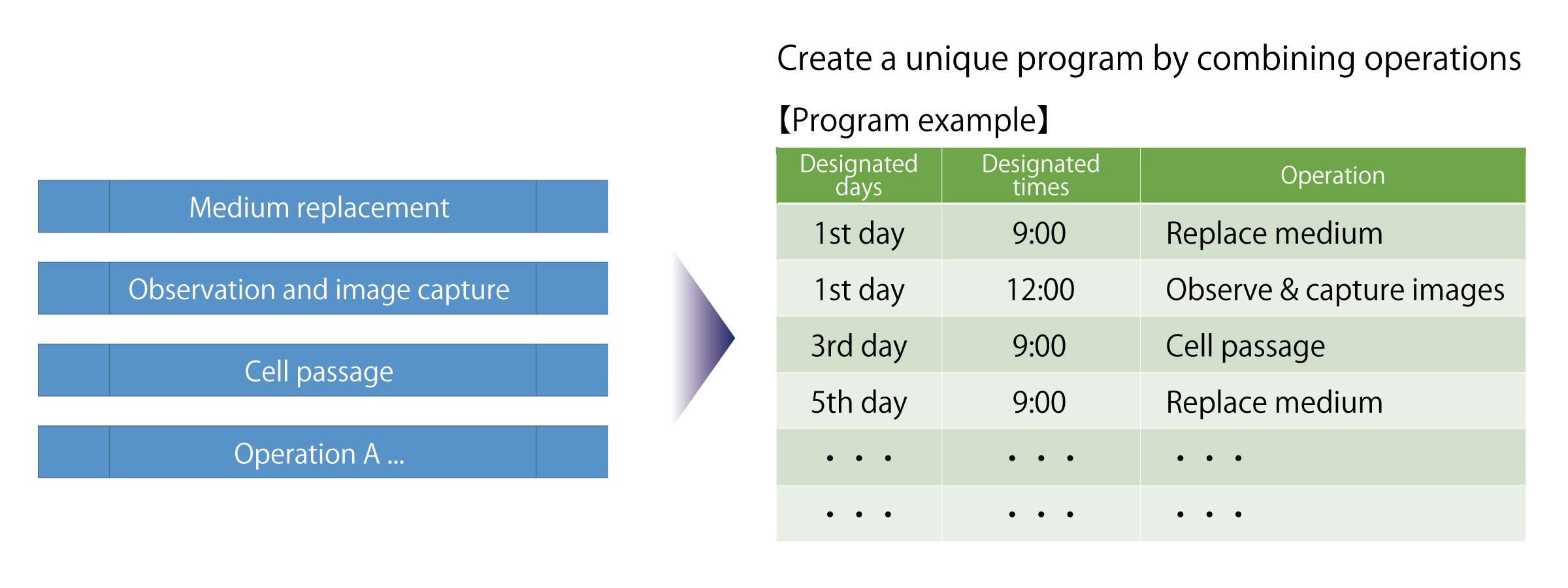

The device is modularized and can be combined according to need

Modules can be selected and customized to meet user needs

Unique programming is possible

By combining device operations, the user can set up a unique program

# # #

- Disclaimer:

- We would like to note that Panasonic Newsroom is not a place to address personal Customer Service issues. Even though this is not the forum, Panasonic is always eager to resolve your concerns. Our local customer services contacts can be found at Global Support or you can see our list of Social Media Accounts to find the right channel for your queries and concerns.