Mar 06, 2024

- Products & Solutions

- Press Release

- Asia and Oceania

- Business Solution

- Home & Personal Solution

- Air Conditioning

Dec 12, 2019

Products & Solutions / Press Release

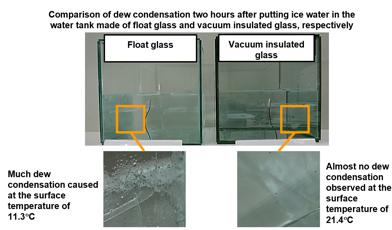

- The company successfully puts into practical use vacuum insulated glass

with the Industry's first(*1) transparent pillars -

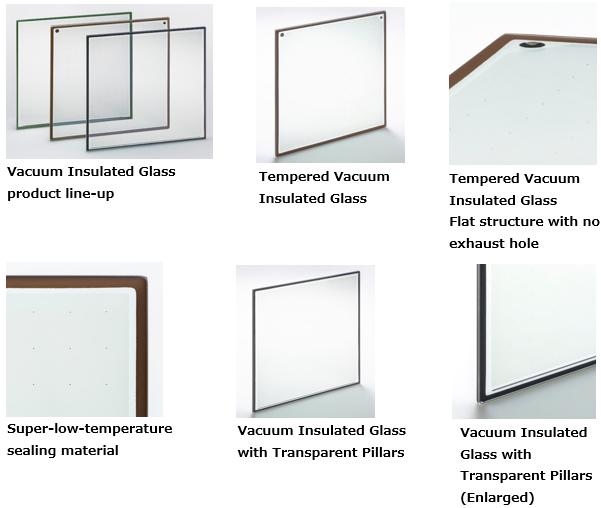

Osaka, Japan - Panasonic Corporation today announced that it has developed tempered vacuum insulated glass and another vacuum insulated glass with transparent pillars that it has successfully put into practical use for the first time in the industry(*1).

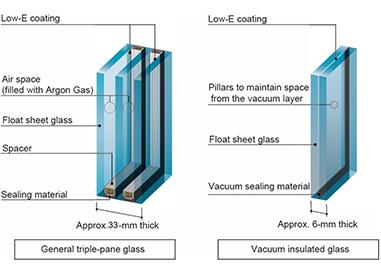

In 2017, Panasonic entered the vacuum insulated glass business by applying its plasma display panel development and manufacturing technology. Since then, Panasonic has been manufacturing vacuum insulated glass having the industry's top-class(*2) heat insulation performance for glass with a total thickness of 6 mm and has introduced the glass in automatic glass door systems for refrigerators used in convenience stores and supermarkets manufactured by Hussmann Corporation, the U.S. refrigerator and freezer showcase manufacturer wholly-owned by Panasonic. In April 2019, Panasonic launched production of the glass for the European housing market jointly with AGC Inc. and expanded the glass business for the replacement of existing windowpanes and other applications.

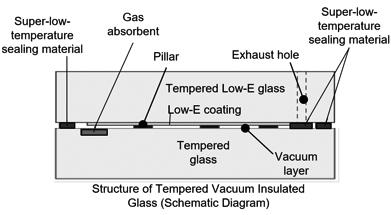

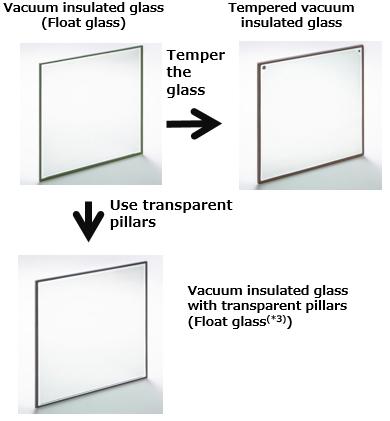

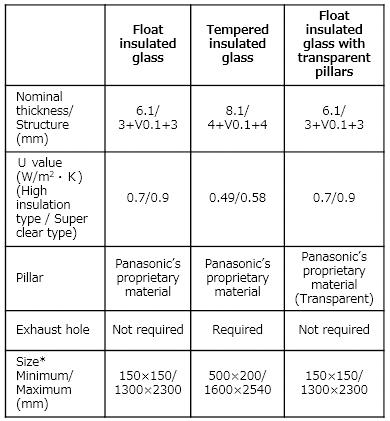

Panasonic will release the tempered vacuum insulated glass in the first half of the next fiscal year that starts April1, 2020 in addition to the float vacuum insulated glass(*3) the company has been offering. Vacuum insulated glass is manufactured by vacuum-sealing two sheets of glass with vacuum sealing material melted at high temperature, while tempered glass generally drops in strength when it is heated at high temperature. Panasonic newly developed its proprietary "Super-low-temperature sealing material" and consequently achieved the sealing of tempered glass in a temperature zone in which it does not drop in strength. The technology capable of manufacturing both the float(*3) and the tempered vacuum insulated glass is Panasonic's proprietary technology.

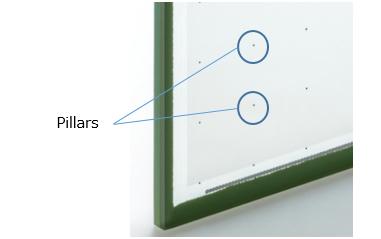

Furthermore, Panasonic has successfully put vacuum insulated glass with the transparent "pillars for supporting the vacuum layer" into practical use for the first time in the industry(*1) and will release this glass during the next fiscal year. Since the pillars are subjected to extremely high pressure, they are normally made of high-strength, non-transparent material such as metal. Panasonic developed "Highly heat-insulated transparent material" and consequently succeeded in the development of vacuum insulated glass with transparent pillars. This vacuum insulated glass provides noiseless visibility suppressing the presence of pillars more than ever before while still delivering a high level of heat insulating performance.

Panasonic has named its vacuum insulated glass "Glavenir" with the aim of enhancing awareness of this vacuum insulated glass and offer it for a wide variety of applications.

Panasonic will offer vacuum insulated glass that makes the best use of its proprietary development and technological capabilities for a variety of different applications and contribute to achieving a society that is more sustainable.

Panasonic Glavenir is tempered vacuum insulated glass that is highly strengthened and unlikely to cause injury because it fragments into granules when it breaks. Vacuum insulated glass is manufactured by sealing two sheets of glass with sealing materials melted under high temperature. Generally, the strength of tempered glass is increased by heating it at high temperature and quenching it. However, the strength drops when it is heated at high temperature again. By using the newly-developed proprietary "Super-low-temperature sealing material," Panasonic achieved sealing of two sheets of tempered glass in a temperature zone in which it does not drop in strength. Panasonic's proprietary technology capable of manufacturing both the float(*3) and the tempered vacuum insulated glass has made best use of the expertise cultivated during the development and manufacture of plasma displays.

Panasonic developed its vacuum insulated glass based on the concept of a flat appearance with no protrusions on the glass surface. The tempered vacuum insulated glass released by Panasonic this time also achieves a flat structure using its proprietary sealing method.

Equipment, which is installed in public spaces and requires the strength and safety of glass(e.g. automatic door systems, refrigerator and freezer showcases, and windows of public facilities and office buildings)

Panasonic has succeeded in putting into practical use vacuum insulated glass with transparent pillars used to support the vacuum layer for the first time in the industry(*1). Each pillar is subjected to high pressure of approx. 200 MPa. Since normal atmospheric pressure is approx. 0.1 MPa, the pillar bears pressure approx. 2,000 times higher than the pressure to which we are usually subjected. For this reason, pillars have mostly been made of high-strength material such as metal so far and rarely made of transparent material. Panasonic has recently developed "High-strength transparent insulating material" and consequently succeeded in manufacturing vacuum insulated glass with transparent pillars. By using the pillars in combination with the proprietary structure where the "Gas absorbent" that absorbs gases generated from the components of the glass under vacuum is mounted on the invisible edge of the glass, the vacuum insulated glass successfully provides a low-noise field of vision with the presence of pillars suppressed more than ever before while maintaining high insulation performance.

Normal pillars

Normal pillars Transparent pillars

Transparent pillarsPlaces where aesthetics and low-noise field of vision are required.(e.g. refrigerator and freezer showcases, wine cellars, exhibition showcases, and aquariums)

Along with this enhancement of its business capabilities, Panasonic has named its vacuum insulated glass "Glavenir" to raise awareness of this business. In the hope that vacuum glass will provide glass with breakthrough insulation performance and create a future new world, Panasonic named the vacuum insulated glass after "Glass + Avenir (French meaning future in English)."

To present an example of vacuum insulated glass that makes full use of Panasonic's proprietary technology, Panasonic will exhibit the vacuum insulated glass that allows video display in combination with a transparent display under development in its booth at the SANDS EXPO Venue of the CES 2020 held in Las Vegas, USA from January 7, 2020.

Panasonic's proprietary sealing method achieves a flat appearance(*4) with no exhaust hole and its cap. This allows multiple sheets of the glass to be transported stacked on top of each other and further to meet a wide variety of applications.

Since the glass is made of lead-free material, it can be used safely even in the food industry.

Panasonic Corporation is a worldwide leader in the development of diverse electronics technologies and solutions for customers in the consumer electronics, housing, automotive, and B2B businesses. The company, which celebrated its 100th anniversary in 2018, has expanded globally and now operates 582 subsidiaries and 87 associated companies worldwide, recording consolidated net sales of 8.003 trillion yen for the year ended March 31, 2019. Committed to pursuing new value through innovation across divisional lines, the company uses its technologies to create a better life and a better world for its customers. To learn more about Panasonic: https://www.panasonic.com/global.

The content in this website is accurate at the time of publication but may be subject to change without notice.

Please note therefore that these documents may not always contain the most up-to-date information.

Please note that German, French and Chinese versions are machine translations, so the quality and accuracy may vary.