Osaka, Japan - Panasonic Corporation has developed a 12V Energy Recovery System for idle-stop vehicles that uses nickel metal hydride (Ni-MH) batteries for automobiles. This system allows the energy generated during braking to be stored in the batteries and use the stored energy to power the vehicle's electrical components, thus ensuring power availability even when the engine is not being used. In addition, as the system is designed to supply power to the drive assist motor as well, it helps improve the vehicle's fuel economy.

The system includes new Ni-MH battery cells developed by the company. Based on Panasonic's technology accumulated in the development of batteries for hybrid electric vehicles (HEV), the new battery cells offer higher charging efficiency and durability under high temperatures, compared to existing Ni-MH battery cells. That increases flexibility in the installation of the system, as it can be placed in the engine compartment which reaches high temperatures.

With a rising environmental consciousness, consumers are increasingly opting for eco cars such as HEVs as well as vehicles employing idle-stop systems in the pursuit of improved fuel economy. However, because conventional idle-stop systems depend on a single lead-acid battery to take care of all electrical needs of the vehicle, from restarting the engine to running the air-conditioner and other electrical components with the engine off, the battery is put under too much load. Panasonic's new 12V Energy Recovery System not only solves this problem but also improves fuel economy and extends the service life of the main lead-acid battery, thus contributing to increased functionality of idle-stop systems.

Panasonic is strengthening the development and business of lithium-ion and Ni-MH batteries for eco cars, and already has a successful record of supplying batteries for electric vehicles, plug-in hybrids and HEVs for multiple automobile manufacturers around the world. Panasonic started developing Ni-MH batteries for HEVs in 1997, and has been mass producing them since 2004. Panasonic's Ni-MH batteries are durable and able to maintain a high charging/discharging capacity over an extended period of time. This is supported by the company's unique battery manufacturing technologies, including polar plate sintering technology*1. Panasonic also has many years of experience in building battery systems, such as those incorporating batteries with a battery control that optimizes the performance of each battery.

Panasonic will continue to accelerate the development and commercialization of high performance batteries and battery systems to expand its eco car battery business on a global scale.

*1 Technology involving firing of metal nickel powder at high temperatures for manufacturing rigid, porous nickel substrate.

[Major Features]

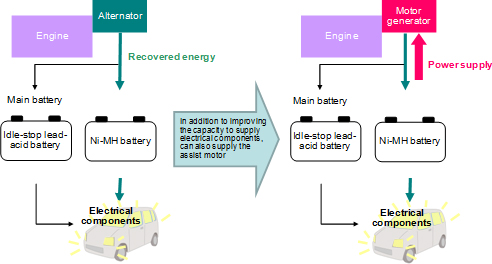

1. The new energy recovery system improves fuel economy by supplying the recovered energy to the electrical components and assist motor.

The 12V Energy Recovery System for idle-stop vehicles converts deceleration energy into electrical energy so that it is able to reduce the need of power generation by the gasoline engine. This system is designed to complement the performance of main lead-acid battery by supplying power to the vehicle's electrical components as well as the drive assist motor, thus increasing the functionality of idle-stop systems and improving fuel economy. With this 12V Energy Recovery System, Panasonic aims to approximately double*2 the fuel economy improvement rate of existing idle-stop systems.

*2 Comparison of fuel economy improvement rates between "gasoline-engine vehicles versus those with a conventional idle-stop system" and "gasoline vehicle versus those with Panasonic's 12V Energy Recovery System." The actual fuel economy improvement effects will vary according to the vehicle type and the conditions of use.

[Concept Diagram of 12V Energy Recovery System]

2. The new system employs Ni-MH batteries that can be fitted to existing idle-stop systems without the use of a transformer. Outstanding high temperature performance enables installation inside the engine compartment.

The 12V Energy Recovery System, which is designed to be connected in parallel with the main lead-acid battery, has the same 12 V voltage as the main battery. Unlike some systems that require a transformer to regulate voltage, depending on the type of batteries used, Panasonic's 12V system uses 10 1.2 V Ni-MH battery cells, eliminating the need for voltage transformation. This helps lower the system's costs and use energy more efficiently.

The main lead-acid battery is often placed in the engine compartment. As the new energy recovery system can be installed in the same compartment, it is possible to reduce cable connection resistance and simplify wiring. To enable such a setup, Panasonic has developed battery cells that can endure high-temperatures in the engine room. Using technology acquired in developing HEV batteries, Panasonic has improved the battery design, such as the polar plates, electrolytic solution and other battery parts, to increase charging efficiency and improve durability in high temperature environments. As a result, the cell's maximum charging/discharging temperature is significantly improved from 60°C to 75°C*3 compared to existing cells. This ensures that the system can be installed in the engine compartment, and provides a high degree of design flexibility for the system's installation.

*3 From tests conducted by Panasonic on its existing products and the new cell

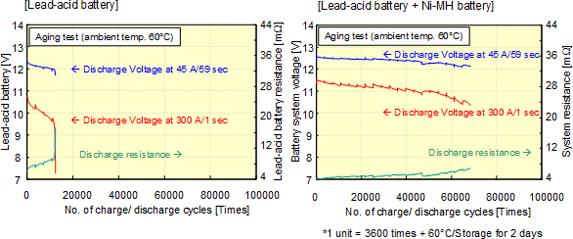

3. Contribution to increased service life of the main lead-acid battery.

Idle-stop systems depend on the main battery to power the air-conditioner and other electrical components of the vehicle when the vehicle is in idle-stop mode with the engine off. And because the engine is repeatedly turned on and off, a large load is put constantly on the battery. When the 12V Energy Recovery System is connected in parallel with the lead-acid battery, the current flows preferentially to the Ni-MH battery with a smaller battery resistance, lessening the load on the lead-acid battery.

Tests conducted by Panasonic, using a 12V Energy Recovery System together with a lead-acid battery, have confirmed that the service-life of the main battery was extended by approximately six times*4 compared to when a lead battery was used alone.

*4 Results of charge/discharge life tests for idle-stop (SBA S0101) conducted at 60°C aging conditions by Panasonic. A Panasonic lead-acid battery (Q-55) and 12V Energy Recovery System were used.

[12V Energy Recovery System]

Battery: 10 x D size Ni-MH battery cells

Voltage: 12 V

Capacity: 6 Ah

[Ni-MH battery cell for automobiles]

About Panasonic

Panasonic Corporation is a worldwide leader in the development and manufacture of electronic products in three business fields, consumer, components & devices, and solutions. Based in Osaka, Japan, the company recorded consolidated net sales of 7.85 trillion yen for the year ended March 31, 2012. Panasonic's stock is listed on the Tokyo, Osaka, Nagoya and New York (NYSE:PC) Stock Exchanges. The company has the vision of becoming the No. 1 Green Innovation Company in the Electronics Industry by the 100th year of its founding in 2018. For more information on Panasonic, its brand and commitment to sustainability, visit the company's website at http://panasonic.net/.

Media Contacts:

- Tokyo Public Relations Office

Panasonic Corporation - Tel: +81-(0)3-3574-5664 Fax: +81-(0)3-3574-5699

- Panasonic News Bureau

- Tel: +81-(0)3-3542-6205 Fax: +81-(0)3-3542-9018