Mar 24, 2025

- Produkte & Lösungen

- Pressemitteilung

Sep 13, 2023

Produkte & Lösungen / Pressemitteilung

Einführung des Servosystems der MINAS A7-Familie, das die branchenweit höchste *2 Bewegungsleistung erreicht hat [1]

Osaka, Japan–Panasonic Industry Co., Ltd. (Hauptsitz: Kadoma-shi, Osaka; Representative Director, President, CEO: Shinji Sakamoto) gab heute die Markteinführung des Servosystems der MINAS A7-Familie bekannt. Es erreicht die branchenweit höchste *2 Bewegungsleistung und ist mit künstlicher Intelligenz ausgestattet, die erstmals in der Branche automatisch eine präzisere Abstimmung durchführt, die der von menschlichen Experten überlegen ist *1. Das Produkt wird im Januar 2024 in Japan und anschließend weltweit eingeführt.

*1: Stand der Kommerzialisierung des Allzweck-Servosystems am 13. September 2023. Daten Panasonic Industry.

*2: Stand: 13. September 2023, als Servomotor (Leistung: 200 W) und Servoverstärker (Leistung: 200 W). Daten Panasonic Industry.

Die Technologie zur Automatisierung der Servomotor-Abstimmung hat sich weiterentwickelt. Allerdings konnten mit der herkömmlichen automatischen Abstimmung keine zufriedenstellenden Ergebnisse für Geräte erzielt werden, die eine hochpräzise Positionierungsleistung erfordern, wie z. B. Geräte zur Halbleiterfertigung und Montagemaschinen für elektronische Komponenten. Diese Dinge erforderten ausgefeilte manuelle Tuning-Fähigkeiten, die von als Experten anerkannten Ingenieuren erworben wurden.

Dieses Produkt automatisiert solch präzise Tuning-Arbeiten, die bisher nur menschlichen Experten vorbehalten waren, durch die vollständige Nutzung der KI-Technologie. Es ist möglich, die Positionierungs-Einschwingzeit [2], die ein Indikator für die Positionierungsleistung ist, um 45 % *3 (im Vergleich zu früheren menschlichen Ergebnissen) und die für die Abstimmung erforderliche Betriebszeit um 90 % oder mehr *4 zu reduzieren.

*3: Messungen in der experimentellen Umgebung von Panasonic. Gemessene Einschwingzeit bis zur Annäherung der Positionierungsabweichung an den vorgegebenen Positionierungsbereich.

*4: Messungen in der experimentellen Umgebung von Panasonic. Gemessene Tuning-Betriebszeit, bis sich die Positionierungsabweichung dem vorgegebenen Positionierungsbereich annähert.

Darüber hinaus ist die Geschwindigkeitsreaktionsfrequenz [3], die die Grundleistung des Servosystems darstellt, mit 4,0 kHz oder mehr die höchste *1 der Branche (1,25-mal *5 so viel wie bei herkömmlichen Produkten von Panasonic), und die Encoderauflösung [4] ist mit 27 Bit (134.217.728 Impulse/Umdrehung) der branchenweit höchste *1. Diese Ergebnisse werden zur Verbesserung der Geräteleistung beitragen.

*5: Im Vergleich zum herkömmlichen Servomotor der MINAS A6-Serie von Panasonic (Leistung: 200 W). Daten Panasonic Industry.

Panasonic Industry wird dazu beitragen, die Leistung der Kundenausrüstung zu verbessern und gleichzeitig Energieeinsparungen durch die Reduzierung von Abfällen aufgrund der minderwertigen Qualität der mit solchen Geräten hergestellten Produkte und durch eine Verbesserung der Gerätezykluszeit zu erzielen [5].

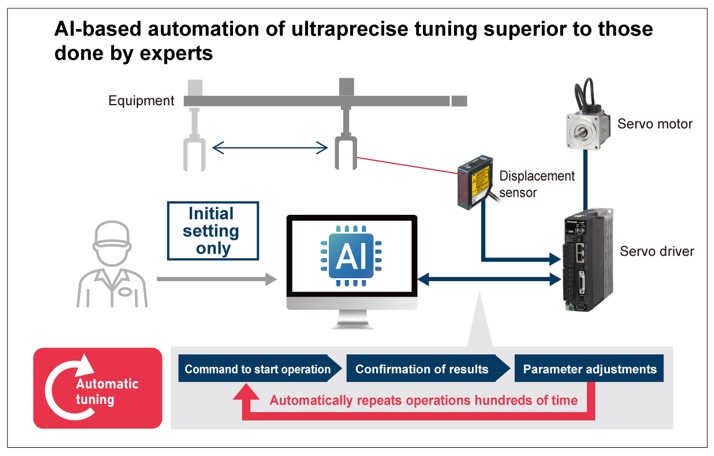

Das unabhängig entwickelte precAIse TUNING von Panasonic, das die KI-Technologie voll ausnutzt, ermöglicht eine präzise automatische Abstimmung. Es automatisiert sogar Aufgaben in Bereichen, in denen Experten aufgrund der unbefriedigenden Leistung herkömmlicher automatischer Tuning-Funktionen früher Zeit mit der manuellen Abstimmung verbrachten.

Geräte, die eine hochpräzise Positionierungsgenauigkeit erfordern, wie z. B. Geräte zur Halbleiterfertigung und Montagemaschinen für elektronische Komponenten, erfordern eine Abstimmung, die die große Anzahl von Parametern für die Eigenschaften jedes einzelnen Geräts präzise reguliert. Dies erforderte das anspruchsvolle Wissen, die Sinne und die Fähigkeiten erfahrener Ingenieure.

Darüber hinaus gibt es Fälle, in denen selbst solche Experten mehrere Tage bis eine Woche benötigen, um die geforderte Leistung zu erbringen. Ausgestattet mit PrecAIse TUNING automatisiert dieses Produkt die präzise Abstimmung, die zuvor manuell von Experten durchgeführt wurde, um Benutzern durch einfache Anfangseinstellungen eine hervorragende Positionierungsleistung zu ermöglichen.

Die Einschwingzeit für die Positionierung, ein Indikator für die Positionierungsleistung, wird im Vergleich zu Expertenergebnissen um 45 % reduziert, und die für die Abstimmung erforderliche Betriebszeit wird um 90 % oder mehr reduziert.

Die Ausrüstung, die KI nutzt, reduziert die menschliche Tuning-Arbeitszeit um 90 %

〈Vergleich von Tuning-Ergebnissen durch einen menschlichen Experten und KI-basiertem automatischem Tuning〉

Die Ausrüstung von AI reduziert die Einschwingzeit der Positionierung um 45 %

Die Encoderauflösung des Servomotors wird mit 27 Bit (134.217.728 Impulse/Zeit) erreicht, ein Branchenhöchstwert. Die Geschwindigkeitsreaktionsfrequenz, die die Steuerleistung von Servoverstärkern angibt, erreicht einen Branchenhöchstwert von 4,0 kHz oder mehr (das 1,25-fache des herkömmlichen Produkts von Panasonic). Diese Ergebnisse werden zur Verbesserung der Positionierungs- und Verarbeitungsgenauigkeit der Geräte der Kunden beitragen. Darüber hinaus erreicht der Servomotor eine maximale Drehzahl von 7.150 U/min. Die Verbesserung der Betriebsgeschwindigkeit der Geräte wird zu kürzeren Zykluszeiten beitragen.

Normalerweise erfordert die Steuerung von Servomotoren komplexe Steuerprogramme in Steuerungen wie SPS. Der für dieses Produkt verwendete Servoverstärker mit direkter Sensorrückmeldung (Wegregelung) verbessert die Reaktionsfähigkeit des Systems vom Sensoreingang bis zum Servomotorausgang. Der Verstärker erfasst die Sensordaten direkt und ohne Umweg über Steuerungen. Da keine komplexen Steuerprogramme für Steuerungen erstellt werden müssen, ist eine schnelle und präzise Steuerung möglich. Dies trägt zur Reduzierung des Arbeitsaufwands für die Entwicklung von Kundenprogrammen bei.

Panasonic Industry plant, in Zukunft die Produktpalette anwendungsspezifischer Servoverstärker schrittweise zu erweitern, beispielsweise um Produkte mit hochpräziser Portalsteuerung und Sensor-Direktrückmeldung (Druckregelung).

Halbleiterfertigungsanlagen, Montagemaschinen für elektronische Komponenten, Werkzeugmaschinen, Industrieroboter und mehr

|

Stromversorgung |

Einphasig 100 V AC, einphasig/dreiphasig 200 V AC |

|---|---|

|

Nennleistung des Motors |

200 W und 400 W |

|

Steuerbefehlsmethode |

EtherCAT-Kommunikation (Serienname: A7B-Serie) |

|

Anwendungsspezifische Servoverstärker |

Direkte Sensorrückführung (Verdrängungsregelung) |

Mit Blick auf die Stärkung globaler Produktionssysteme wird die Produktion zusätzlich zur Zhuhai-Fabrik in Guangdong, China, die derzeit die Produktionsbasis unseres Servosystems darstellt, in der Tatsuno-Fabrik in der Präfektur Hyogo, Japan, stattfinden.

[1] Bewegungsleistung

Leistung in Bezug auf Reaktionsfähigkeit und Positionierungsgenauigkeit, die Indikatoren für die Bewertung des Servosystems sind. Die Leistung wird im Allgemeinen anhand der Geschwindigkeitsreaktionsfrequenzen bewertet. Grundlegende Spezifikationen wie die Encoderauflösung sind Elemente, die sich aus Geschwindigkeitsreaktionsfrequenzen ergeben.

[2] Einschwingzeit der Positionierung

Die verstrichene Zeit vom Abschluss des Positionierungsbefehls bis zum Erreichen des Zielpositionierungsbereichs, der durch die erforderliche Genauigkeit bestimmt wird.

[3] Geschwindigkeitsreaktionsfrequenz

Ein Indikator dafür, wie schnell ein Motor auf einen bestimmten Geschwindigkeitsbefehl reagieren kann. Je größer der Frequenzwert, desto höher ist die Regelleistung des Motors.

[4] Encoder-Auflösung

Die Anzahl der ausgegebenen Impulse pro Motorumdrehung. Je größer der Wert, desto höher ist die Genauigkeit des Encoders.

[5] Zykluszeit

Tatsächlich benötigte Zeit zur Herstellung eines Produkts. Sie wird als Gleichung aus der regulären Betriebspausenzeit pro Tag, dividiert durch die tatsächliche tägliche Produktionsmenge, ausgedrückt.

|

Über Panasonic Industry Co., Ltd. Panasonic Industry Co., Ltd. wurde am 1. April 2022 als Betriebsgesellschaft für das Gerätegeschäft der Panasonic-Gruppe gegründet. Die Mission des Unternehmens lautet: „Wir ebnen den Weg in eine bessere Zukunft und tragen weiterhin durch eine Vielzahl von Gerätetechnologien zu einer Betriebsgesellschaft Gesellschaft bei.“ Das Unternehmen beschäftigt weltweit rund 42.000 Mitarbeiter und erzielte im Geschäftsjahr zum 31. März 2023 einen Nettoumsatz von 1.149,9 Milliarden Yen. Vor dem Hintergrund des Arbeitskräftemangels in der Fertigung, der explosionsartigen Zunahme des Datenvolumens durch die Entstehung der informationsbasierten Gesellschaft und der gestiegenen Anforderungen an Umwelt und Sicherheit in der Mobilitätsgesellschaft wird sich das Unternehmen auf Bereiche konzentrieren, in denen kontinuierliche Weiterentwicklung erforderlich ist, und seinen Kunden weiterhin Mehrwert durch einzigartige Material- und Prozesstechnologien wie Kondensatoren, kompakte Servomotoren, EV-Relais und elektronische Materialien bieten. Erfahren Sie mehr über Panasonic Industry unter https://www.panasonic.com/global/industry. |

Der Inhalt dieser Website ist zum Zeitpunkt der Veröffentlichung korrekt, kann jedoch ohne vorherige Ankündigung geändert werden.

Bitte beachten Sie daher, dass diese Dokumente möglicherweise nicht immer die aktuellsten Informationen enthalten.

Bitte beachten Sie, dass es sich bei der deutschen, französischen und chinesischen Version um maschinelle Übersetzungen handelt, sodass Qualität und Genauigkeit variieren können.